Ultrasonic micro grinding and processing equipment and technology thereof

A processing equipment and micro-grinding technology, which is applied to metal processing equipment, grinding/polishing equipment, and parts of grinding machine tools, etc., can solve the problems of complex grinding process, easy wear of micro-grinding wheels, and difficult dressing of micro-grinding wheels. The effect of various processing methods, simple processing process and high workpiece accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

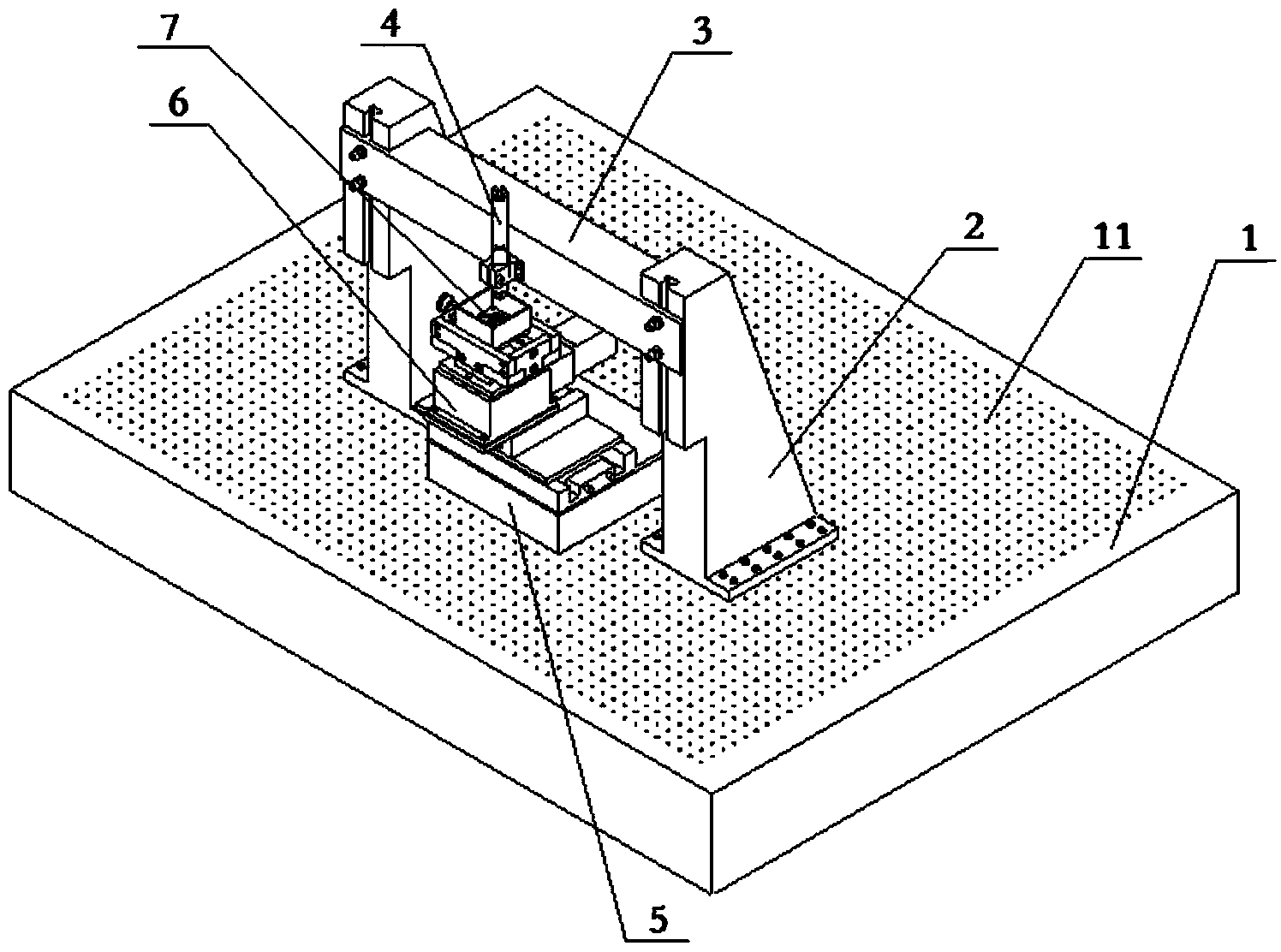

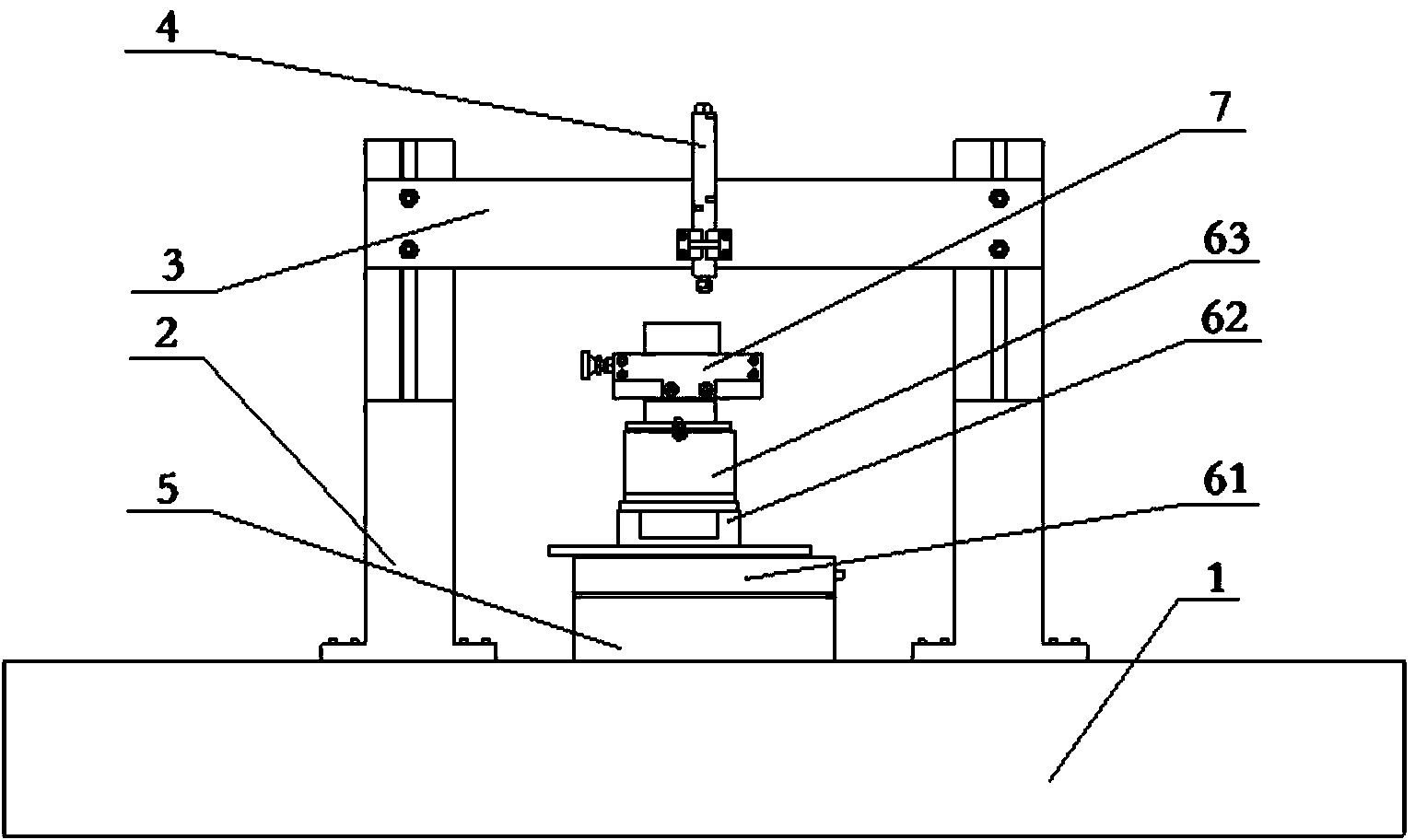

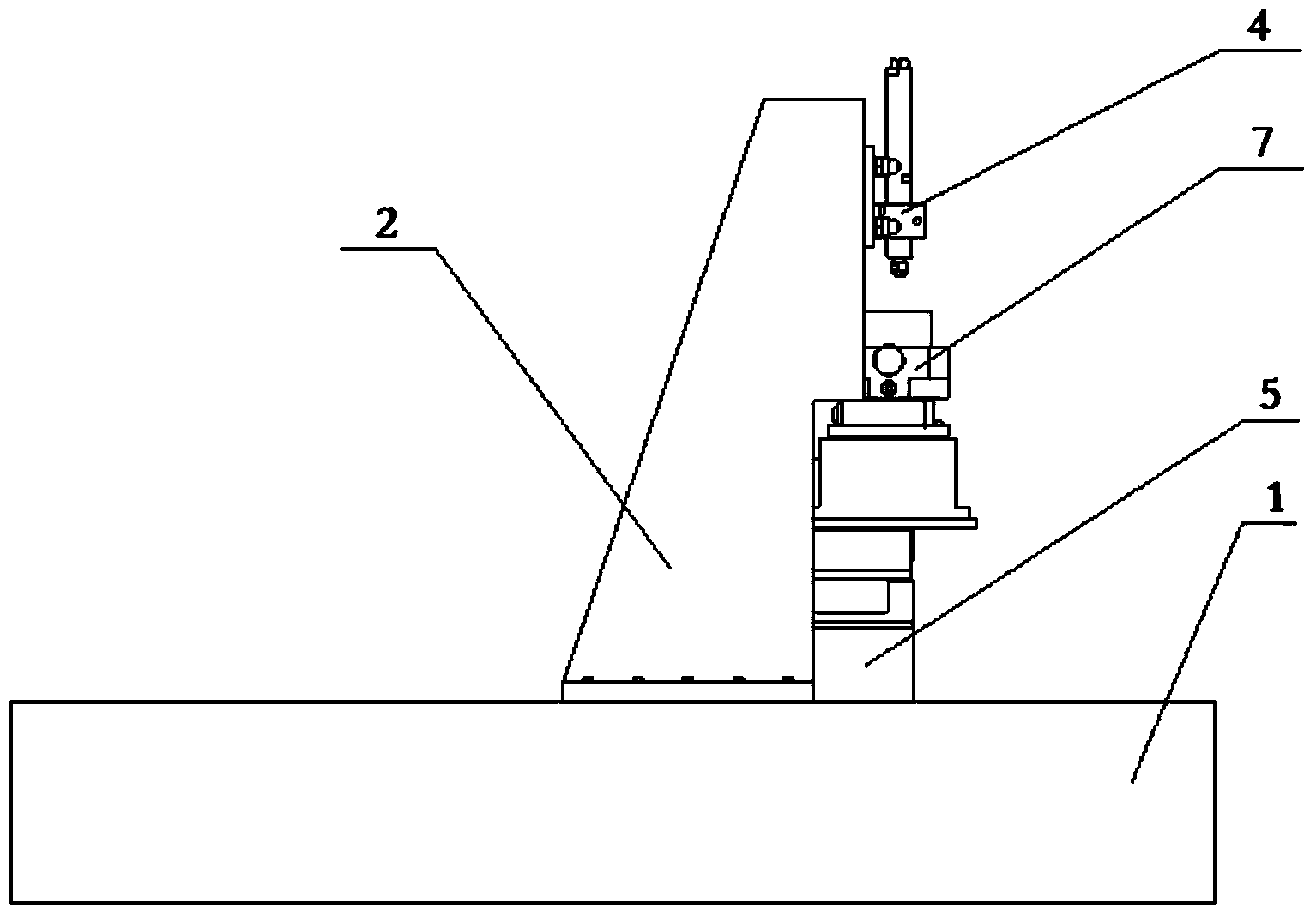

[0049] Such as Figure 1 to Figure 3 As shown, it is a kind of ultrasonic micro-grinding processing equipment provided by the present invention, including a vibration isolation table 1, and the vibration isolation table 1 is provided with threaded holes 11 uniformly distributed with 25x25, preferably, the threaded holes 11 is an M5 threaded hole, and the threaded hole 11 is used for installing other components in the ultrasonic micro-grinding equipment. The left and right symmetrical columns 2 are fixed on the vibration isolation workbench 1, and the columns 2 are connected by crossbeams 3. The columns 2 are T-shaped guide groove columns, and the crossbeams 3 form a gantry-type frame. The beam 3 is provided with a spindle assembly 4 that drives the grinding device to rotate at a high speed, and an ultrasonic vibration platform 7 is provided below the spindle assembly 4, and the ultrasonic vibration platform 7 is driven by a piezoelectric stack actuator 75, Two-dimensional ult...

Embodiment 2

[0069] The difference between the present embodiment and the second embodiment is that the vibrating plate 70 of the ultrasonic micro-grinding equipment in the present embodiment is not provided with a water tank, and the workpiece 8 is dry-ground. In this embodiment, the spindle assembly 4 is fixed on the upper surface of the beam 3 to grind the workpiece 8 in the circumferential direction.

[0070] Using the ultrasonic micro-grinding equipment in this embodiment to carry out micro-grinding process on the workpiece, including the following steps:

[0071] A determine the position of the fixture 77 fixed on the vibrating plate 70 according to the shape, position and material of the workpiece 8 to be processed, and select 4 mounting holes in the 8 mounting holes according to the fixed position of the vibrating plate 70; The form of the grinding process determines that the working frequency of the piezoelectric stack actuator 75 in the ultrasonic vibration platform is 20-23KHz, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com