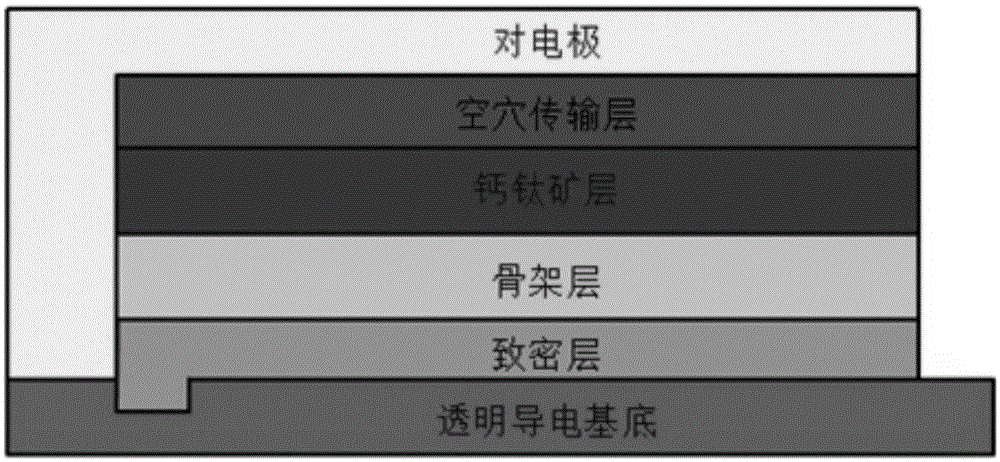

Mesoporous perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large transmission loss, low electron collection efficiency, low current, etc., to improve short-circuit current density and open-circuit voltage, reduce Interfacial resistance and the effect of carrier interfacial recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Preparation of transparent conductive substrate:

[0052] Etch the FTO conductive glass with 1:1 concentrated hydrochloric acid and zinc powder to form the required electrode pattern, and ultrasonically clean it with alkaline detergent aqueous solution for 60 minutes. Wash with deionized water, absolute ethanol, and acetone in sequence, then dry with cold dry air, and treat at a high temperature of 510°C for 20 minutes.

[0053] 2) Prepare the dense layer:

[0054] Spin-coat a 5-40 mM tetraisopropyl titanate isopropanol solution on the FTO transparent conductive glass at a speed of 3000-6000 rpm for 30 s. Then high temperature treatment at 510°C for 20 minutes to form 5-150nm TiO 2 dense layer.

[0055] 3) Preparation of perovskite light-absorbing layer:

[0056] Prepared using a two-step method, 350-500 mg of PbI 2 Dissolve in 1mL DMF (N,N-dimethylformamide), heat at 70°C for 12h to dissolve. This PbI2 solution was then spin-coated on BaSnO 3 On the skeleton ...

Embodiment 2

[0064] 1) Prepare a transparent conductive substrate. With embodiment 1.

[0065] 2) Prepare a dense layer. With embodiment 1.

[0066] 3) Prepare the skeleton layer:

[0067] Dilute commercial TiO with absolute ethanol at a mass ratio of 3:1 2 slurry, and then stirred for 12h until the diluted slurry was completely mixed evenly. The mixed slurry is spin-coated on the dense layer at a rotation speed of 2000-6000rpm for 30s. Then high temperature treatment at 510°C for 20 minutes to form 200-600nm thick TiO 2 Skeleton layer.

[0068] 4) Prepare the perovskite light-absorbing layer. With embodiment 1.

[0069] 5) Prepare the hole transport layer. With embodiment 1.

[0070] 6) Preparation of electrodes. With embodiment 1.

[0071] 7) Test:

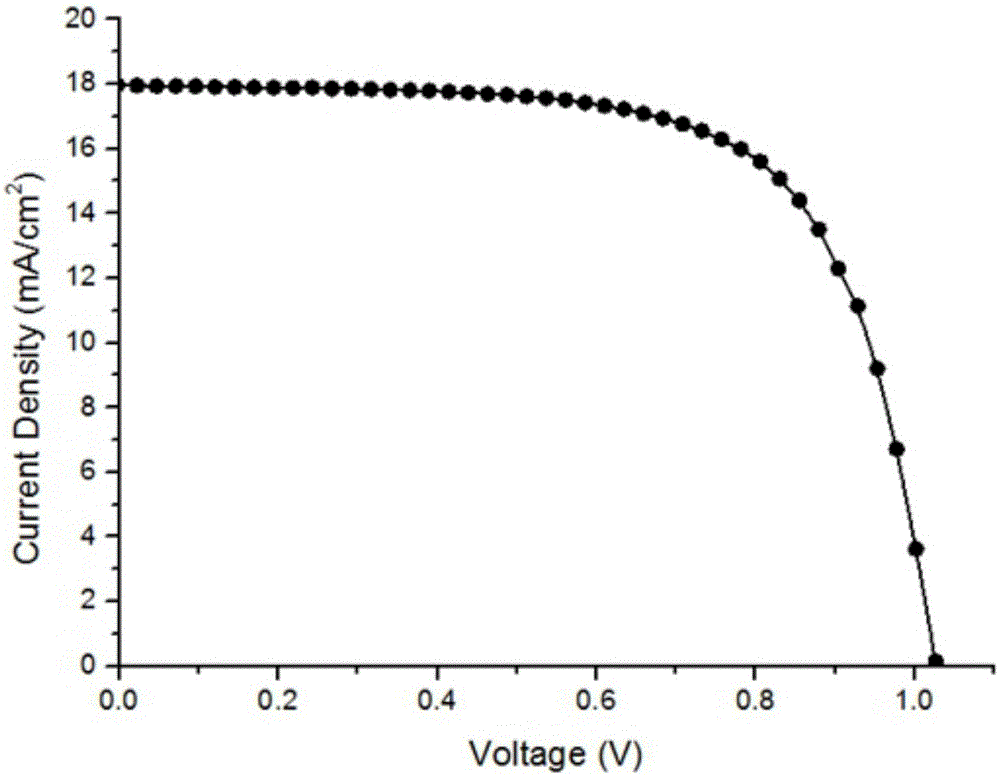

[0072] The test conditions are spectral distribution AM1.5G, light intensity 1000W / m 2 The standard light source, the effective area of the battery is 0.09cm 2 . After optimizing the parameters, the obtained photoelectric c...

Embodiment 3

[0074] 1) Prepare a transparent conductive substrate. With embodiment 1.

[0075] 2) Prepare a dense layer. With embodiment 1.

[0076] 3) Prepare the skeleton layer:

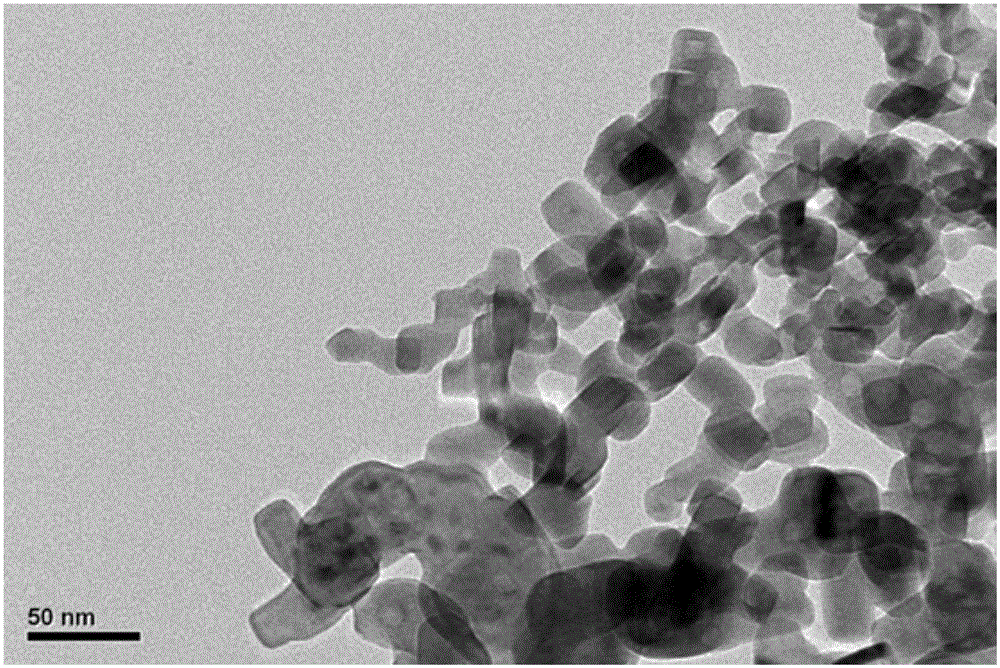

[0077] Dilute BaSnO with absolute ethanol at a mass ratio of 3:1 3 slurry, and then stirred for 12h until the diluted slurry was completely mixed evenly. The mixed slurry was spin-coated on the dense layer at a rotation speed of 3000 rpm for 30 s. Then high temperature treatment at 510°C for 20 minutes to form 200nm thick BaSnO 3 Skeleton layer.

[0078] 4) Prepare the perovskite light-absorbing layer. With embodiment 1.

[0079] 5) Prepare the hole transport layer. With embodiment 1.

[0080] 6) Preparation of electrodes. With embodiment 1.

[0081] 7) Test:

[0082] The test conditions are spectral distribution AM1.5G, light intensity 1000W / m 2 The standard light source, the effective area of the battery is 0.09cm 2 . After optimizing the parameters, the obtained photoelectric conversion eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com