Novel method for improving uniformity and crystallinity of organic-inorganic perovskite thin film

An inorganic calcium and thin film technology, applied in photovoltaic power generation, electrical components, electrical solid devices, etc., can solve the problems of affecting the output voltage, poor film continuity, large surface roughness, etc., to avoid pinhole defects and improve uniformity. , the effect of high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

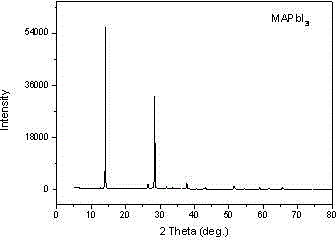

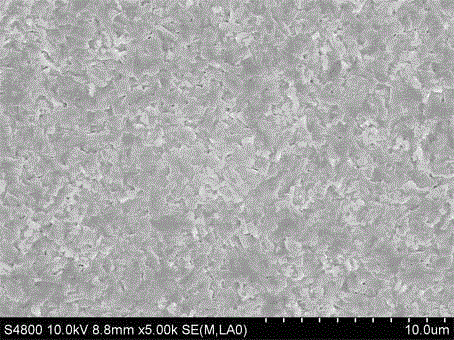

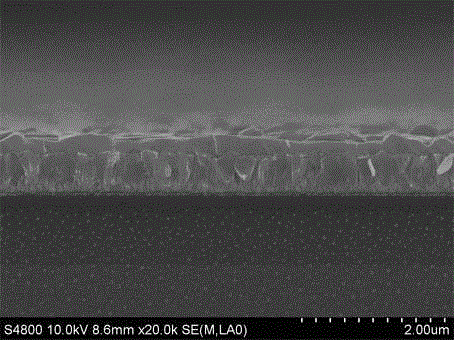

Embodiment 1

[0020] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30 min to obtain dense TiO 2 film. Spin-coating TiO on re-dense thin films 2 Slurry, TiO 2 particle size ~20 nm, and then a further 500 o C heat treatment for 30 min to obtain TiO 2 mesoporous film. Secondly, according to the molar percentage 1:0.5 PbI 2 and PbCl 2 mixed in DMSO solution to prepare a solution with a mass ratio of 40%, and then spin-coated on dense TiO 2 film, heated to 100 o C, 60 min, evaporate the solvent, and finally get MAPbI 3 perovskite structure. Finally, a hole transport layer Spiro-OMeTAD was spin-coated on the perovskite layer, gold electrodes were vapor-deposited, and a solar cell device was assembled to obtain a photoelectric conversion efficiency of 13.2%.

[0021]

Embodiment 2

[0023] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30 min to obtain dense TiO 2 film. Secondly, according to the molar percentage 1:0.5 PbI 2 and PbI(OH) were mixed in DMSO solution to prepare a solution with a mass ratio of 40%, and then spin-coated on dense TiO 2 film, heated to 100 o C, 60 min, evaporate the solvent, and finally get MAPbI 3 perovskite structure. Finally, a hole transport layer P3HT was spin-coated on the perovskite layer, and a gold electrode was vapor-deposited to assemble a solar cell device, and a photoelectric conversion efficiency of 12.2% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com