Perovskite solar cell and preparation method of perovskite solar cell by solution method

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems that nano-particle ZnO solution cannot be stored for a long time, and achieve the effects of large-scale production, simplified process flow, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

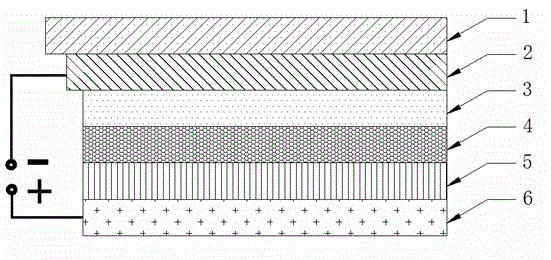

[0035] see figure 1 , the perovskite solar cell consists of a substrate 1 , a transparent electrode layer 2 , an electron transport layer 3 , a light absorbing layer 4 , a hole transport layer 5 and a top electrode layer 6 from top to bottom.

[0036] Wherein, the material of the substrate 1 is glass or flexible plastic; the material of the transparent electrode layer 2 is indium tin oxide or fluorine tin oxide; the material of the electron transport layer 3 is an electron transport material; the material of the light absorption layer 4 is It is a perovskite structure photovoltaic material; the material of the hole transport layer 5 is a hole transport material; the top electrode layer 6 is a metal electrode. The electron transport material is a metal oxide; the perovskite structure photovoltaic material is ABX 3 Organic-inorganic hybrid perovskite with crystal structure; the hole-transporting material is an organic material or an inorganic material. The electron transport ...

Embodiment 2

[0038] The preparation method of the solar cell described in embodiment 1 comprises the following steps:

[0039] Formulated PbI 2 Solution: PbI 2 The concentration is 1 mol / L, and the solvent is dimethylformamide. Prepare CH 3 NH 3 I solution: concentration 10 mg / mL, dissolved in isopropanol. Formulated TiO 2 Precursor solution: tetrabutyl titanate (tetra-n-butyl titanate) was mixed with ethanolamine at a molar ratio of 1:1, and then dissolved in 2-methoxyethanol solution.

[0040] (1) Select ITO glass with a square resistance of 15Ω / □, a thickness of 3mm, and a transmittance of 85% as the substrate material;

[0041] (2) Coating TiO on the substrate by solution spin coating 2 Precursor solution, low temperature treatment at 150°C to 200°C for 30 minutes on a heating platform to obtain TiO with a thickness of about 30-60nm 2 Thin film as electron transport layer;

[0042] (3) Spin-coat PbI on the substrate deposited with the electron transport layer 2 solution, ...

Embodiment 3

[0047] The preparation method of the solar cell described in embodiment 1 comprises the following steps:

[0048] Formulated PbI 2 Solution: PbI 2 The concentration is 1 mol / L, and the solvent is dimethylformamide. Prepare CH 3 NH 3 I solution: concentration 10 mg / mL, dissolved in isopropanol. Preparation of ZnO precursor solution: zinc acetate (Zn(Ac) 2 2H 2 O) After mixing with ethanolamine at a molar ratio of 1:1, dissolve in 2-methoxyethanol solution.

[0049] 4. Preparation of device functional layer, see figure 1 , mainly including various functional layers stacked on the glass substrate 1 and the transparent ITO electrode 2: electron transport layer 3, light absorbing layer 4, hole transport layer 5, and metal electrode 6, the preparation process is as follows:

[0050] (1) Select ITO glass with a square resistance of 15Ω / □, a thickness of 3mm, and a transmittance of 85% as the substrate material;

[0051] (2) Coating TiO on the substrate by solution spin coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com