Passivation process for back of crystalline silicon solar cell and structure of back-passivated crystalline silicon solar cell

A solar cell, crystalline silicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as destroying passivation effects, and achieve the effects of reducing series resistance, protecting alumina, and reducing surface recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

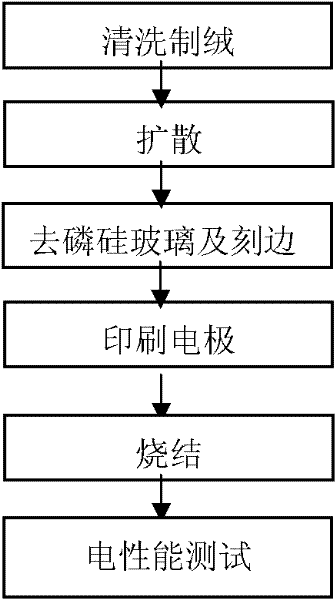

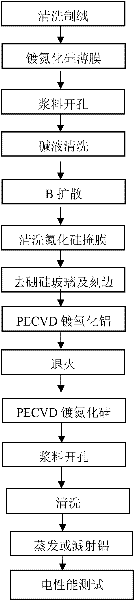

Method used

Image

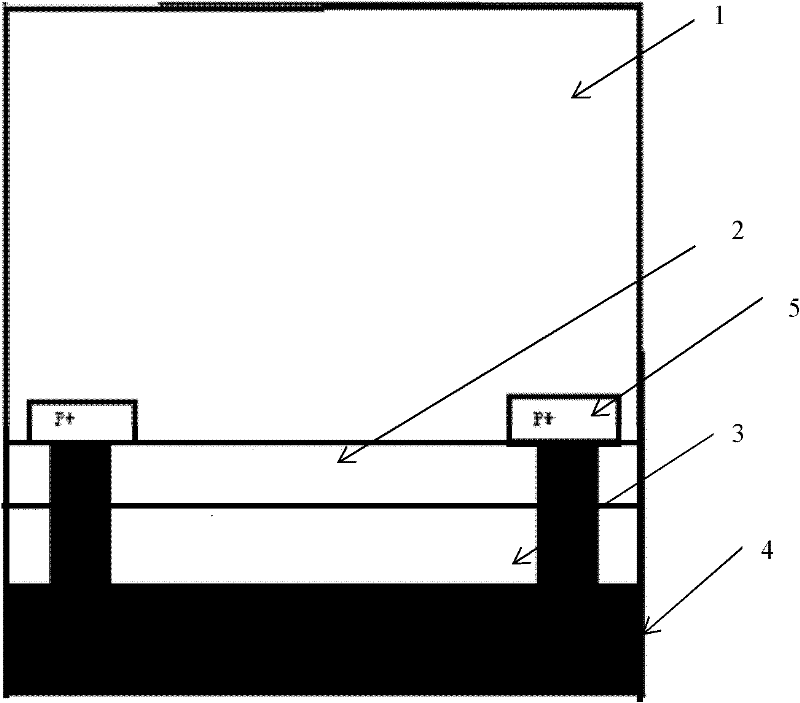

Examples

Embodiment 1

[0028] After the P-type silicon wafer is cleaned and textured, PECVD equipment is used to coat a layer of silicon nitride film on the back surface of the silicon wafer. The slurry opens pores on the surface of the silicon nitride, the size of the pores is 300 microns in diameter and the pitch is 900 microns. The slurry is 1% to 50% ammonium hydrogen fluoride and organic matter. The drying temperature of the slurry is 250°C for 5 to 30 minutes. B re-diffusion is carried out at a certain diffusion temperature. After heavy doping is completed, the silicon nitride mask is removed with 1% to 30% hydrofluoric acid solution or 1% to 50% phosphoric acid solution, and then PECVD is used to plate 30nm on the back surface of the silicon wafer. Aluminum oxide, the coating temperature is 300-350°C; then enter the rapid annealing furnace for annealing in H2 atmosphere, the annealing temperature is 400°C, the annealing time is 15min, and then use PECVD to coat about 100nm of nitride on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com