N-type double-sided solar cell and preparation method thereof

A solar cell, N-type technology, applied in the field of solar cells, can solve problems such as complex process flow, and achieve the effects of simple process steps, precise ion implantation technology, and low light-induced attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] See Figure 1 to Figure 6 as well as Figure 8 As shown, the manufacturing method of an N-type double-sided solar cell provided in this embodiment includes the following steps:

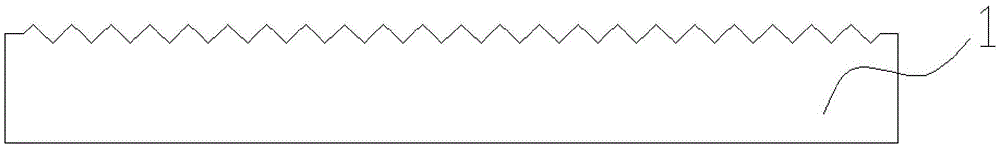

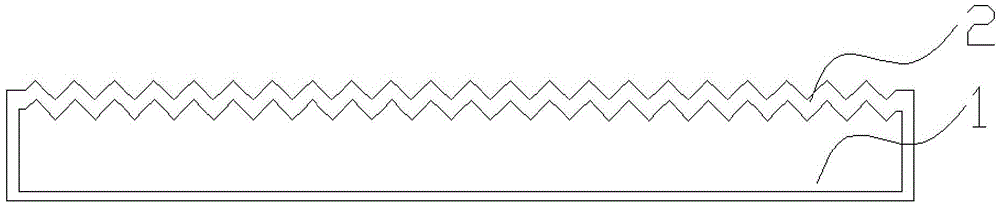

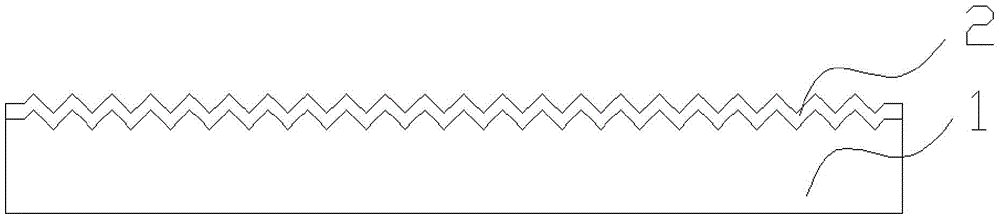

[0044] (1) Select the N-type crystalline silicon substrate and perform texturing treatment on the front surface of the N-type crystalline silicon substrate; in this embodiment, as figure 1 The selected N-type crystalline silicon substrate shown is The crystal orientation of the N-type single crystal silicon substrate 1. The N-type single crystal silicon substrate 1 of this embodiment is an N-type CZ single crystal silicon substrate (single crystal silicon obtained by the Czochralski method), and the N-type single crystal silicon substrate The resistivity of 1 is 0.5 to 15 Ω·cm, preferably 1 to 5 Ω·cm; the thickness of the N-type single crystal silicon substrate 1 is 50 to 300 μm, preferably 80 to 200 μm; the specific method of texturing is the N-type single crystal The silicon substrate 1 is place...

Embodiment 2

[0056] See Figure 1 to Figure 5 as well as Figure 7 , Picture 9 As shown, the manufacturing method of an N-type double-sided solar cell provided in this embodiment includes the following steps:

[0057] (1) Select the N-type crystalline silicon substrate and perform texturing treatment on the front surface of the N-type crystalline silicon substrate; in this embodiment, as figure 1 The selected N-type crystalline silicon substrate is an N-type single-crystal silicon substrate 1 with (100) crystal orientation. The N-type single-crystal silicon substrate 1 of this embodiment is an n-type CZ single-crystal silicon substrate (according to Czochralski growth). Single crystal silicon obtained by the method), the resistivity of the N-type single crystal silicon substrate 1 is 0.5-15 Ω·cm, preferably 1 to 5 Ω·cm; the thickness of the N-type single crystal silicon substrate 1 is 50-300 μm, preferably 80- 200μm; the specific method of texturing treatment is to place the N-type single cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com