Crystalline silicon battery surface passive film and manufacturing method thereof

A technology of crystalline silicon battery and passivation film, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of escaping silicon wafers and insignificant differences in refractive index, and achieve good light transmission and anti-PID effects. , The effect of improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

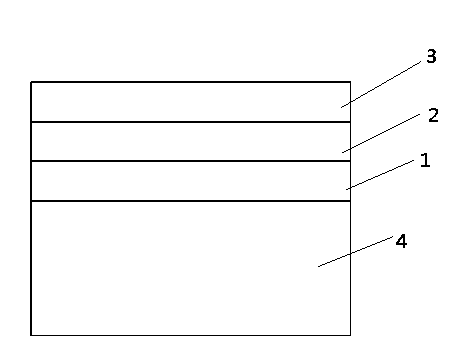

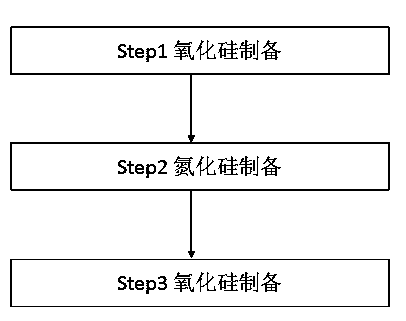

[0027] The production method is as follows: the N-type surface 4 of the P-type crystalline silicon battery is sequentially subjected to the following conventional procedures: primary cleaning, diffusion and secondary cleaning, and the first layer of silicon oxide film is produced by PECVD. The process conditions are: temperature 360 ° C, The nitrogen flow rate is 20L / min, the laughing gas flow rate is 7L / min, the silane flow rate is 2.1L / min, the pressure is 1Torr, the radio frequency power is 5kW, and the duration is 12s to obtain the first silicon oxide film 1 with a thickness of 20nm and a refractive index of 1.5; then use The second layer of silicon nitride film 2 is produced on the first silicon oxide film 1 by PECVD method. The process conditions are: temperature 360°C, nitrogen flow rate 25L / min, ammonia flow rate 0.6L / min, silane flow rate 1.9L / min, pressure 1.2Torr, RF power 8kW, duration 35s, to obtain a silicon nitride film 2 with a thickness of 45nm and a refracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com