Method of oxidation corrosion removing defect layer at the surface of silicon nanowire solar cell

A technology of solar cells and silicon nanowires, applied in chemical instruments and methods, circuits, electrical components, etc., can solve the problems of low surface minority carrier lifetime, low surface reflectivity, and reduced battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

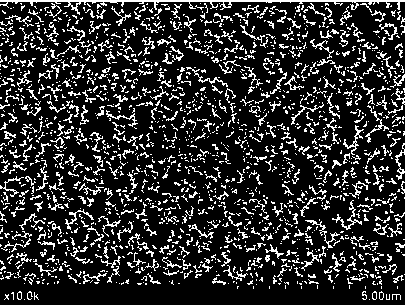

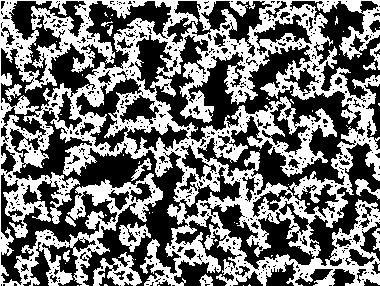

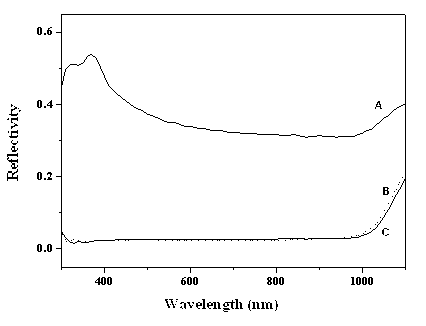

Image

Examples

example 3

[0034] The silicon nanowires in Comparative Example 1 were selected.

[0035] 1. Oxidation

[0036] The silicon oxide layer is grown on the silicon nanowire by dry oxygen oxidation, and the heating temperature is 900 o C, the oxygen flow rate is 50 sccm, the heating time is 30 min, and the thickness of the grown film is 10 nm.

[0037] 2. Corrosion

[0038] The above samples were etched with 1% HF etching solution for 30 min.

[0039] 3. Minority life span measurement

[0040] The measured minority carrier lifetime is 37.3 μs.

example 4

[0042] The silicon nanowires in Comparative Example 1 were selected.

[0043] 1. Oxidation

[0044] The silicon nanowires were put into hydrogen peroxide with a volume concentration of 30%, and soaked at room temperature for 10 minutes.

[0045] 2. Corrosion

[0046] The above samples were etched with 3% HF etching solution for 10 min.

[0047] 3. Minority life span measurement

[0048] The measured minority carrier lifetime is 30.9 μs.

example 5

[0050] The silicon nanowires in Comparative Example 1 were selected.

[0051] 1. Oxidation

[0052] The silicon oxide layer is grown on the silicon nanowire by dry oxygen oxidation, and the heating temperature is 850 o C, the oxygen flow rate is 20 sccm, the heating time is 10 min, and the thickness of the grown film is 5 nm.

[0053] 2. Corrosion

[0054] The above samples were etched with 1% HF etching solution for 30 min.

[0055] 3. Minority life span measurement

[0056] The measured minority carrier lifetime is 38.1 μs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com