Mesophase carbon microspheres, their preparation method and use

A technology of mesocarbon microspheres and hard carbon, applied in chemical instruments and methods, carbon preparation/purification, structural parts, etc. thick and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

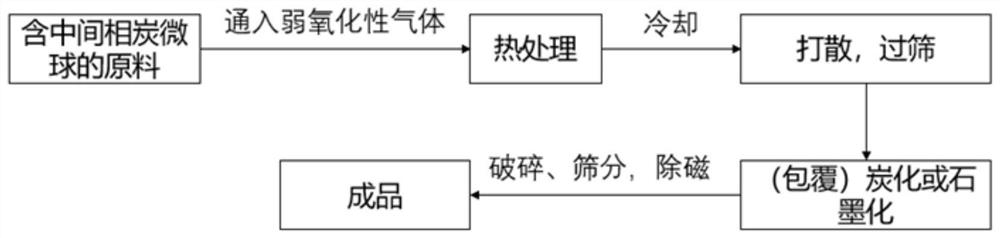

[0053] Second, the present invention provides a method for preparing intermediate phase carbon microspheres as described in the first aspect, the method comprising:

[0054] The intermediate phase carbon microsphere raw materials were oxidized to obtain intermediate phase carbon microspheres with a thickness of < 0.5 μm.

[0055] Since the main component of the intermediate phase carbon microsphere raw material is carbon, having strong reducibility, so the present invention is an oxidation treatment of the intermediate phase carbon microsphere raw material, the shell of the carbon microsphere can be effectively removed partially or completely, so that the resulting intermediate phase carbon microspheres have excellent electrochemical properties. The process of the present invention is simple, can be used in the existing equipment without major modification can be produced.

[0056] In an embodiment of the present invention, the intermediate phase carbon microsphere raw material co...

Embodiment 1

[0104] The present embodiment prepares the negative electrode material according to the following method:

[0105] Mix the carbon microspheres with D50 as 11 μm and the needle-like coke with D50 as 10 μm in a ratio of 8:2, and take 15 kg and put them into the interior of the induction furnace;

[0106]A mixture of gases with a volume ratio of 10:90 into carbon dioxide and argon, a heating rate of 10 °C / min, heating up to 1500 °C, maintained for 2h, and oxidized; Then cooled to room temperature at a rate of 15 °C / min, the powder was scattered, sieved and then graphitized at 2800 °C for 2h, and then crushed and screened to obtain a carbon microsphere graphitization finished product (negative electrode material) with D50 as 9 μm.

Embodiment 2

[0108] The present embodiment prepares the negative electrode material according to the following method:

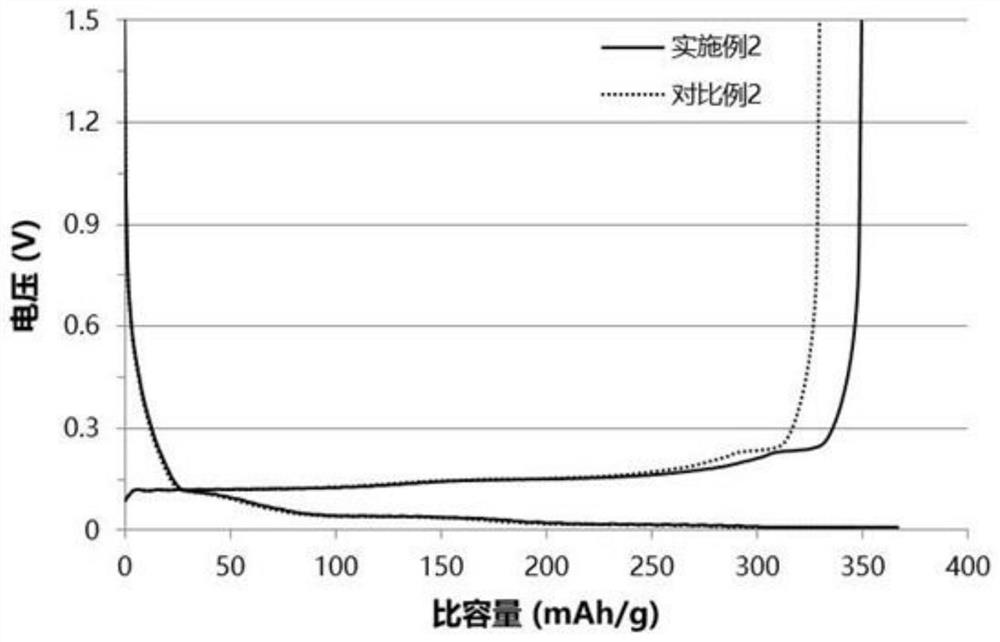

[0109] Put D50 into 12 μm carbon microsphere graphitization finished product (the thickness of the hard carbon shell is 1.5 μm), take 3kg and put it into the inside of the box furnace;

[0110] The volume ratio of water vapor and argon is 15:85 mixed gas, the heating rate is 8 °C / min, the temperature rises to 900 °C, maintains 1.5h; then cooled to room temperature at a rate of 20 °C / min, after crushing and screening, the finished carbon microsphere graphitization product (negative electrode material) with D50 as 11 μm is obtained.

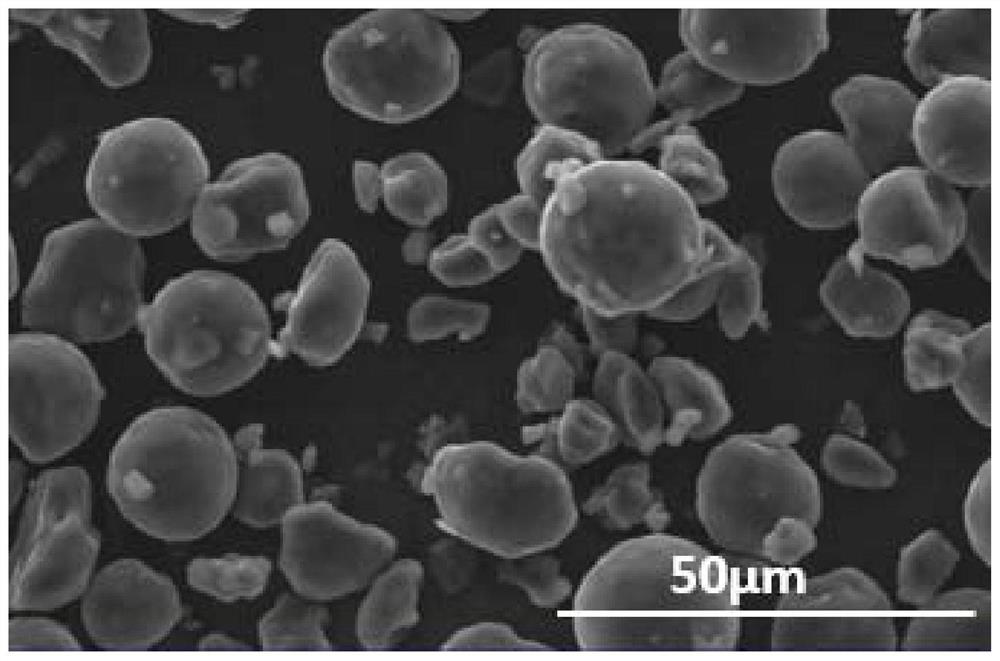

[0111] Figure 2 For the present embodiment obtained a scanning electron microscopy diagram of the negative electrode material, as can be seen from the figure, the particle size uniformity of the negative electrode material is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com