Preparation method and application of elemental silver-doped CZTSSe thin film

A thin-film, elemental technology, applied in the field of thin-film solar cells, can solve the problems of narrow pure phase stable region, and achieve the effects of low reaction conditions, improved photoelectric conversion efficiency, good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Add 0.0699g of elemental copper, 0.0494g of zinc, 0.0859g of tin, 0.0857g of sulfur, and 0.0234g of selenium into 5.5mL of a mixed solution of ethylenediamine and ethanedithiol, heat and stir for 1.5h until completely dissolved, add Stabilizer 1mL (a mixed solution of ethanolamine, thioglycolic acid, and ethylene glycol methyl ether) was heated and stirred for 0.5h to form a cola-colored CZTSSe precursor solution;

[0041] (2) The CZTSSe precursor was spin-coated onto a clean flexible substrate using a homogenizer, then annealed on a hot stage at 350 °C for 1 min, and spin-coated 9 times;

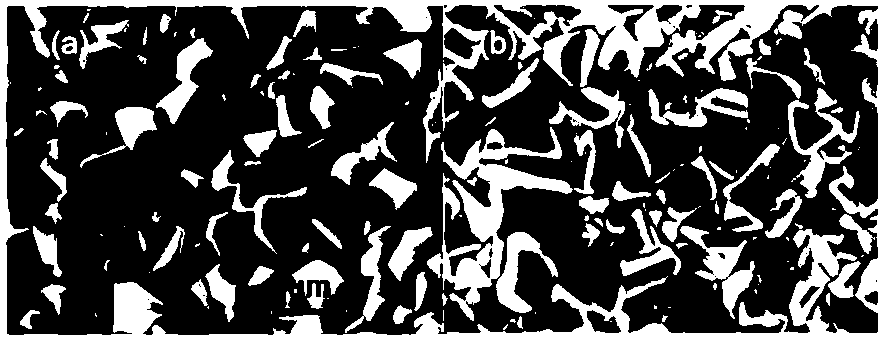

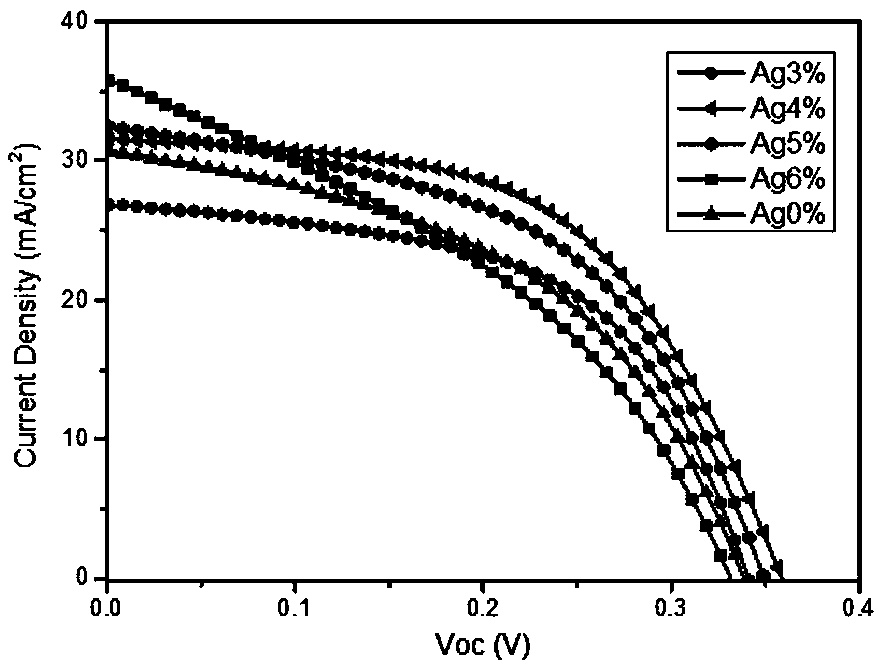

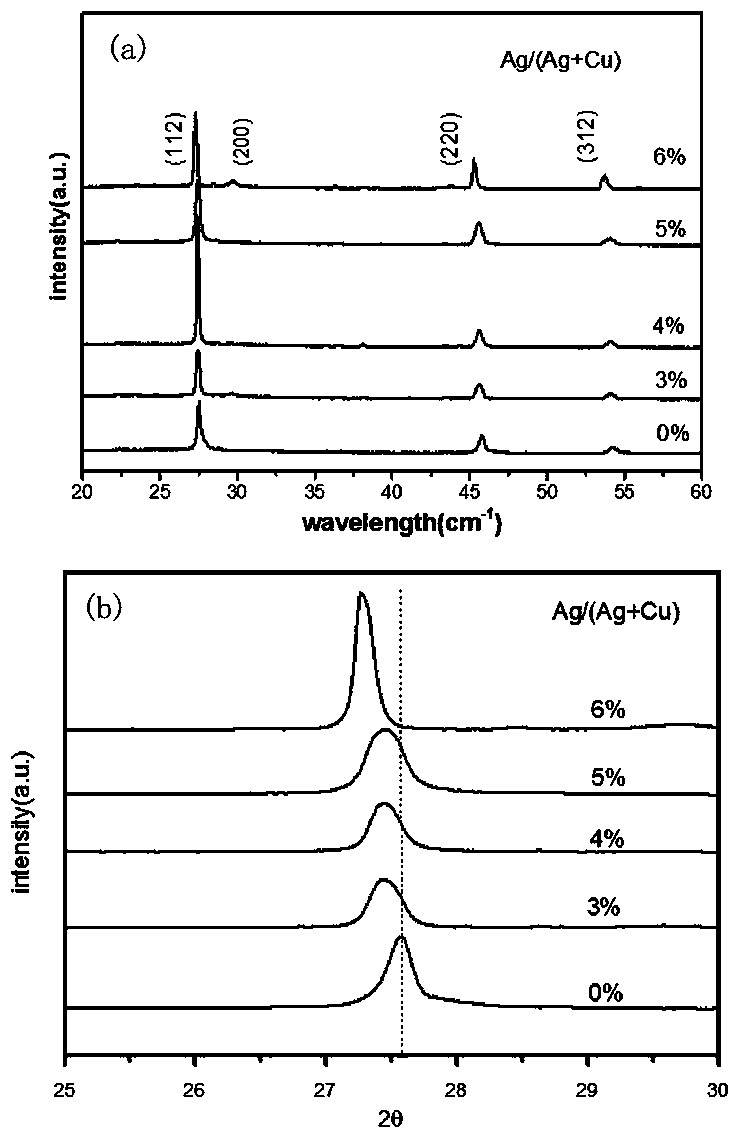

[0042] (3) After the spin coating is completed, the sample is selenized in an RTP selenization furnace at 480°C for 20min, the heating rate is 8°C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N is continuously passed. 2 , with a flow rate of 80 sccm, an undoped CZTSSe film with a thickness of about 2 μm can be obtained (as attached ...

Embodiment 2

[0049] (1) Add 0.0678g of elemental copper, 0.0036g of silver, 0.0494g of zinc, 0.0859g of tin, 0.0857g of sulfur, and 0.0234g of selenium to 5.5mL of a mixed solution of ethylenediamine and ethanedithiol, heat and stir for 1.5h to Dissolve completely, add stabilizer 1mL (mixed solution of ethanolamine, thioglycolic acid, ethylene glycol methyl ether) and heat and stir for 0.5h to form a golden yellow CAZTSSe precursor solution;

[0050] (2) The CAZTSSe precursor was spin-coated onto a clean and clean flexible Mo substrate using a homogenizer, and then annealed on a hot stage at 350 °C for 1 min, and the spin coating was repeated 9 times;

[0051] (3) After the spin coating is completed, the sample is selenized in an RTP selenization furnace at 480°C for 20min, the heating rate is 8°C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N is continuously passed. 2 , the flow rate is 80 sccm, and a CAZTSSe film doped with 3% Ag with a th...

Embodiment 3

[0058] (1) Add 0.0671g of elemental copper, 0.0047g of silver, 0.0494g of zinc, 0.0859g of tin, 0.0857g of sulfur, and 0.0234g of selenium into 5.5mL of a mixed solution of ethylenediamine and ethanedithiol, heat and stir for 1.5h to Dissolve completely, add stabilizer 1mL (mixed solution of ethanolamine, thioglycolic acid, ethylene glycol methyl ether) and heat and stir for 0.5h to form a golden yellow CAZTSSe precursor solution;

[0059] (2) The CAZTSSe precursor was spin-coated onto a clean and clean flexible Mo substrate using a homogenizer, and then annealed on a hot stage at 350 °C for 1 min, and the spin coating was repeated 9 times;

[0060] (3) After the spin coating is completed, the sample is selenized in an RTP selenization furnace at 480°C for 20min, the heating rate is 8°C / s, and the temperature is naturally lowered. During the annealing process, the protective gas N is continuously passed. 2 , with a flow rate of 80 sccm, a CAZTSSe film doped with 4% Ag with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com