Fitting assembly for hood and projectile body

A projectile and assembly technology, which is applied in the field of hood and projectile assembly assembly, can solve problems such as poor closing pressure consistency, low shift output, and high labor intensity, and achieve lower production environment requirements, wide application range, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

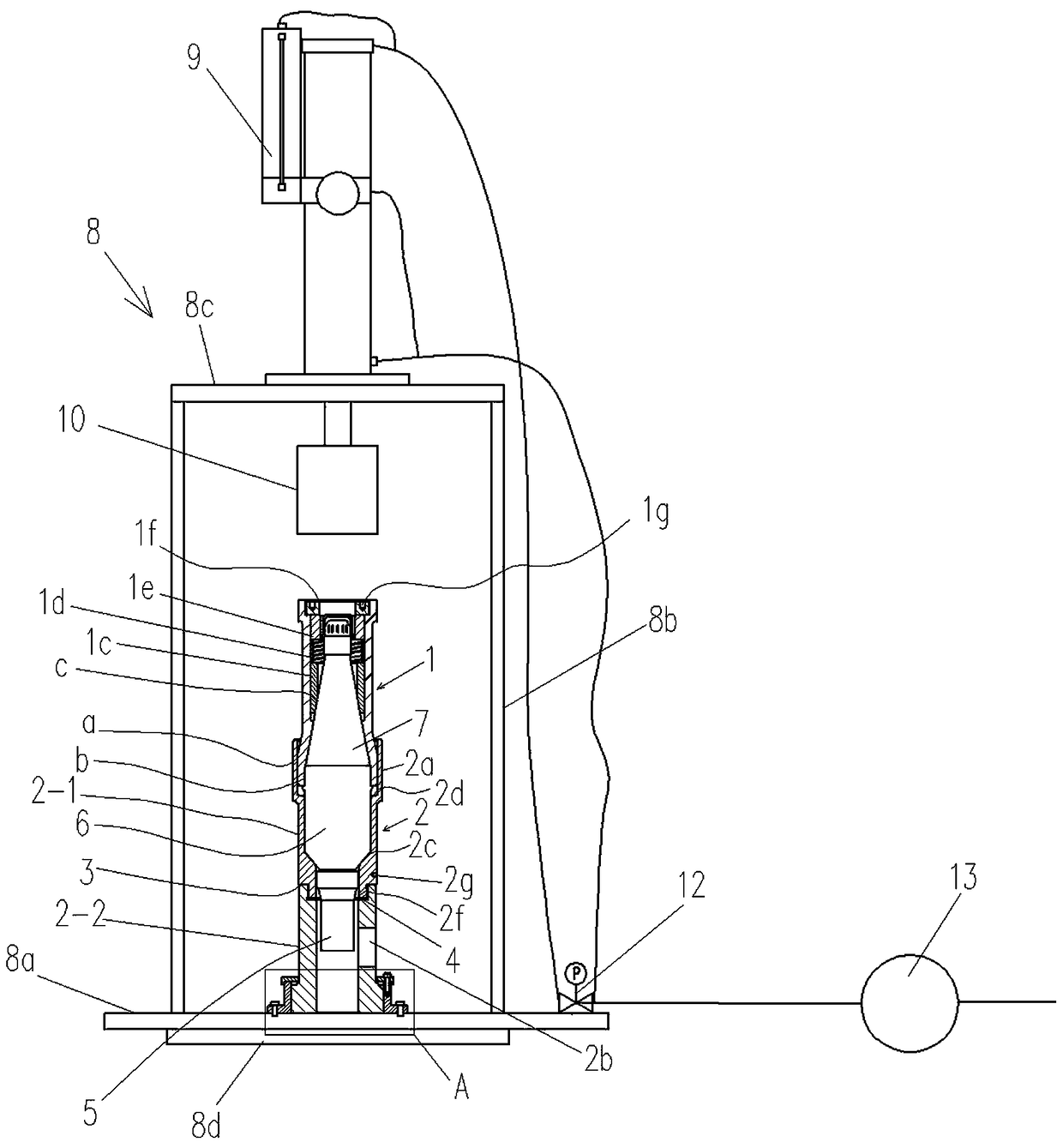

[0015] Such as figure 1 As shown, an assembly assembly for the wind cap and the projectile body, which includes a press device and a corresponding closing device, the press device includes a frame 8, and the frame 8 includes a lower working Table 8a is provided with a group of columns 8b on the lower table 8a, an upper table 8c is provided at the top of the column 8b, and a reinforcing plate 8d is also provided on the back side of the lower table 8a.

[0016] A gas-liquid booster cylinder 9 is arranged on the upper workbench 8c, the lower end of the output shaft of the gas-liquid booster cylinder 9 is located below the upper workbench 8c, and a pressure head 10 is arranged at the lower end of the output shaft. A slot 11 corresponding to the indenter 10 is provided on the lower workbench 8 a below the indenter 10 .

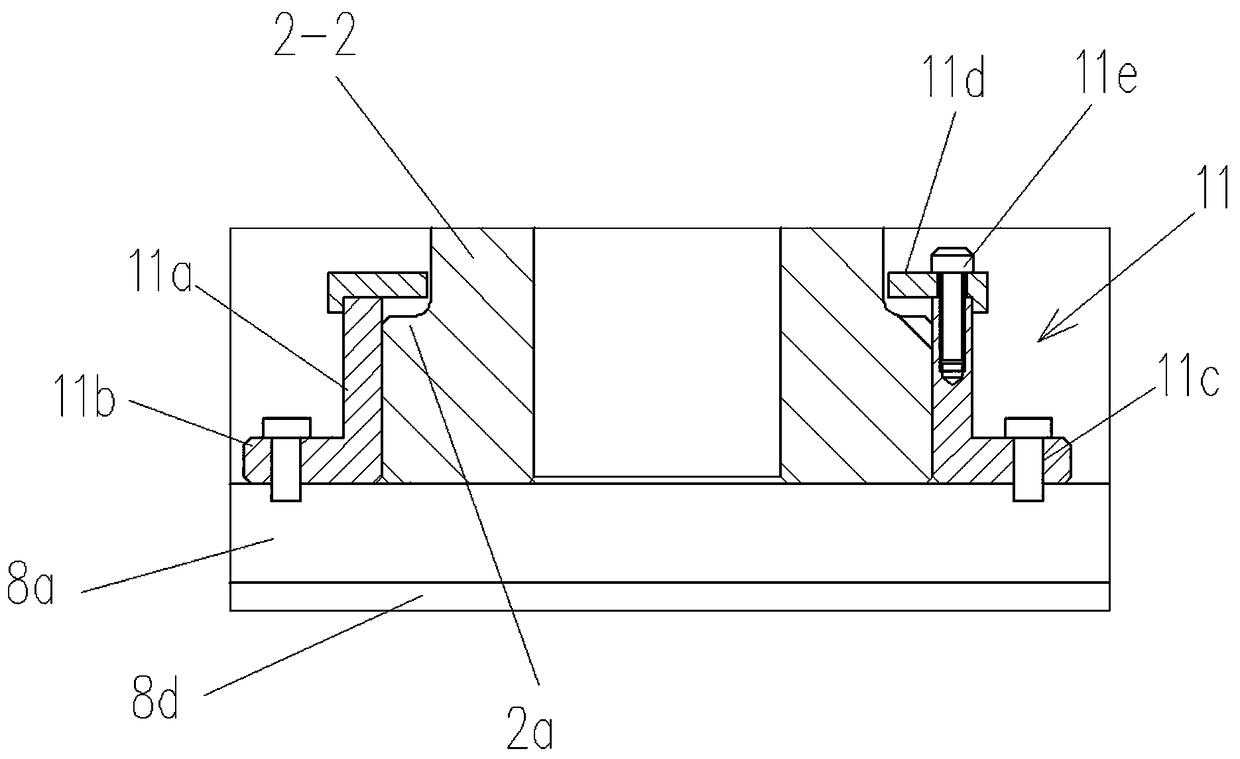

[0017] Such as figure 2 As shown, the clamping groove 11 includes an arc-shaped groove 11 a arranged coaxially with the indenter 10 . An outwardly extending fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com