Preparation method and application of indium doped CZTSSe film

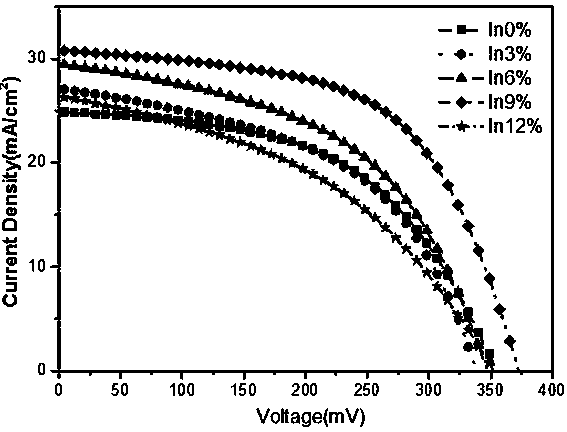

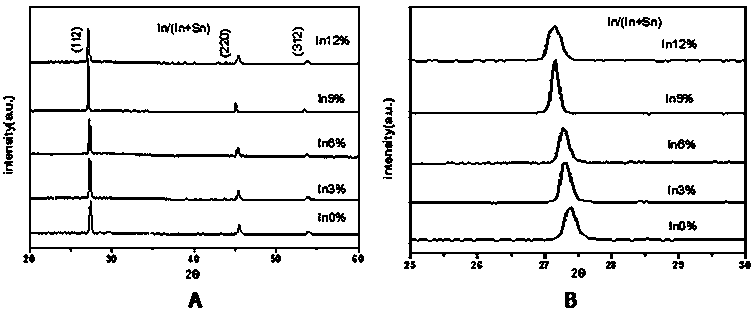

A thin-film, single-substance technology, applied in the field of thin-film solar cells, can solve the problems of large phase difference, achieve simple preparation process, good repeatability and stability, and improve the effect of open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 0.0699g of elemental copper, 0.0494g of zinc, 0.0859g of tin, 0.0857g of sulfur, and 0.0234g of selenium into 5.5mL of a mixed solution of ethylenediamine and ethanedithiol (10:1, v / v), Heat and stir for 1.5h until completely dissolved, add 1mL of stabilizer composed of ethanolamine, thioglycolic acid, ethylene glycol methyl ether (1:1:2, v / v), heat and stir for 0.5h to form a brown-golden CZTSSe precursor solution ;

[0037] (2) Spin-coat the CZTSSe precursor solution onto a clean and clean flexible Mo substrate using a homogenizer, and then anneal on a hot stage at 350 °C for 1 min; repeat the operation 9 times to form a CZTSSe prefabricated layer;

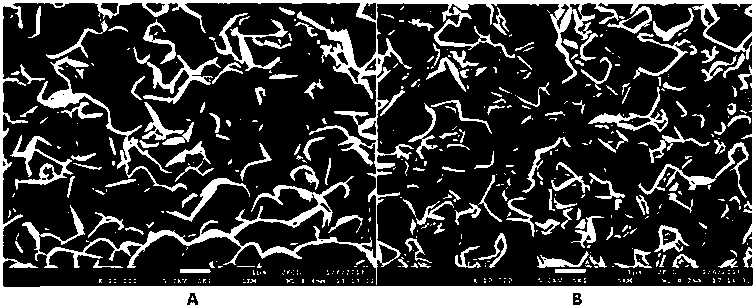

[0038] (3) Continuously feeding protective gas N 2 (The flow rate is 80sccm), the spin-coated sample is placed in an RTP selenization furnace at 550°C for 900s, the heating rate is 8°C / s, and the temperature is naturally lowered to obtain an undoped sample with a thickness of about 2 μm. CZTSSe film.

Embodiment 2

[0040] (1) Add 0.0699g of elemental copper, 0.0025g of indium, 0.0494g of zinc, 0.0833g of tin, 0.0857g of sulfur, and 0.0234g of selenium to 5.5mL of a mixed solution of ethylenediamine and ethanedithiol (10:1, v / In v), heat and stir for 1.5h until completely dissolved, add 1mL of stabilizer composed of ethanolamine, thioglycolic acid, ethylene glycol methyl ether (1:1:2, v / v), heat and stir for 0.5h, and form a golden yellow CZTISSe precursor solution;

[0041] (2) Spin-coat the CZTISSe precursor solution onto a clean and clean flexible Mo substrate using a homogenizer, and then anneal on a hot stage at 350 °C for 1 min; repeat the operation 9 times to form a CZTISSe prefabricated layer;

[0042] (3) Continuously feeding protective gas N 2 (The flow rate is 80sccm), the spin-coated sample is placed in an RTP selenization furnace at 550°C for 900s, the heating rate is 8°C / s, and the temperature is naturally lowered to obtain a doped 3 with a thickness of about 2 μm. %In CZ...

Embodiment 3

[0044] (1) Add 0.0699g of elemental copper, 0.0050g of indium, 0.0494g of zinc, 0.0807g of tin, 0.0857g of sulfur, and 0.0234g of selenium to 5.5mL of a mixed solution of ethylenediamine and ethanedithiol (10:1, v / In v), heat and stir for 1.5h until completely dissolved, add 1mL of stabilizer composed of ethanolamine, thioglycolic acid, ethylene glycol methyl ether (1:1:2, v / v), heat and stir for 0.5h, and form a golden yellow CZTISSe precursor solution;

[0045] (2) Spin-coat the CZTISSe precursor solution onto a clean and clean flexible Mo substrate using a homogenizer, and then anneal on a hot stage at 350 °C for 1 min; repeat the operation 9 times to form a CZTISSe prefabricated layer;

[0046] (3) Continuously feeding protective gas N 2 (The flow rate is 80 sccm), the spin-coated sample is placed in an RTP selenization furnace at 550 °C for 900 s, the heating rate is 8 °C / s, and the temperature is naturally lowered to obtain a doped 6 with a thickness of about 2 μm. %I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com