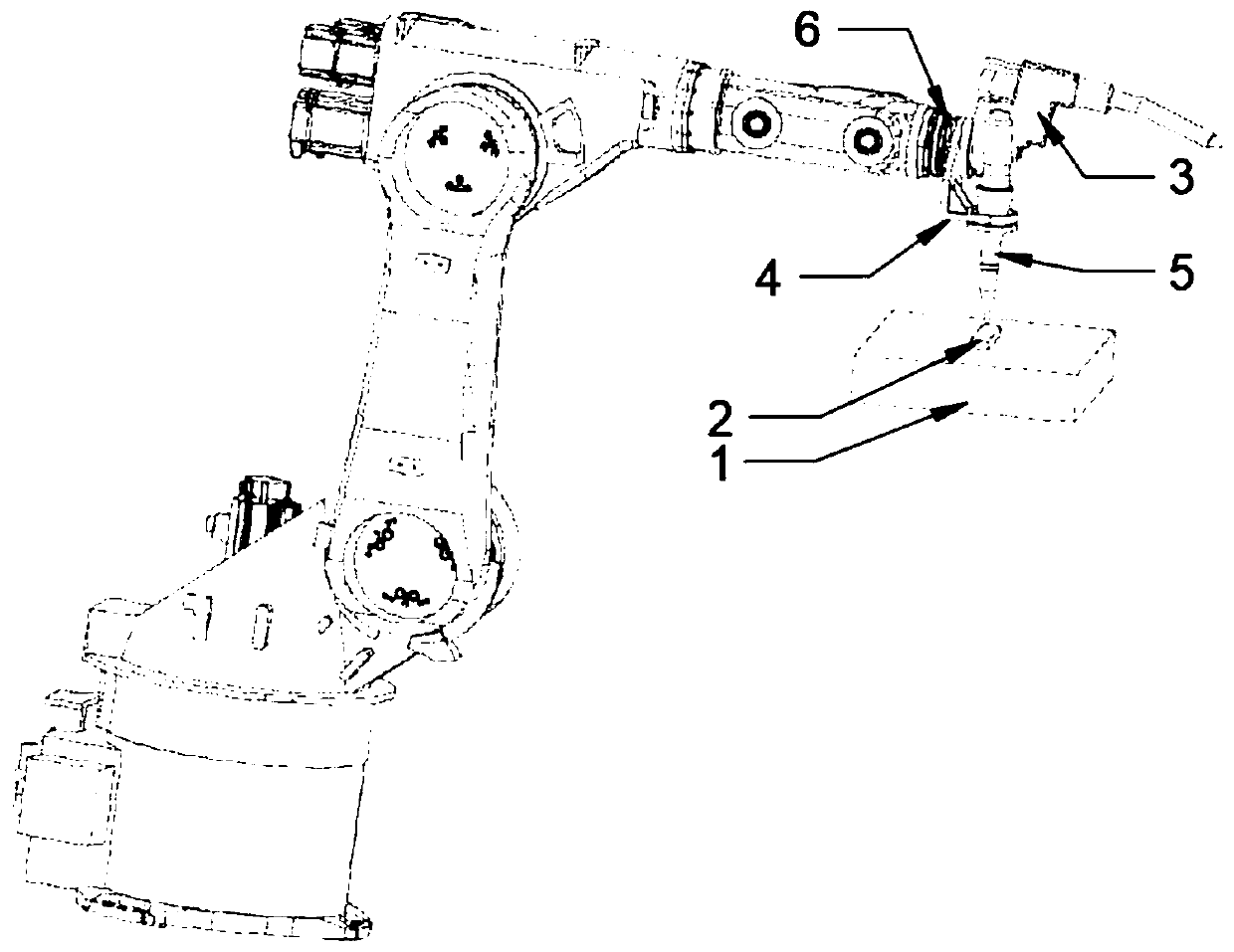

5xxx-series aluminum alloy electric-arc additive surface treatment device

A surface treatment device and technology of aluminum alloy, applied in the field of additive manufacturing, can solve the problems of reducing the deposition efficiency of additive manufacturing, affecting the deposition structure and mechanical properties, and affecting the molding quality, and achieving low price, low requirements, and guaranteed efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

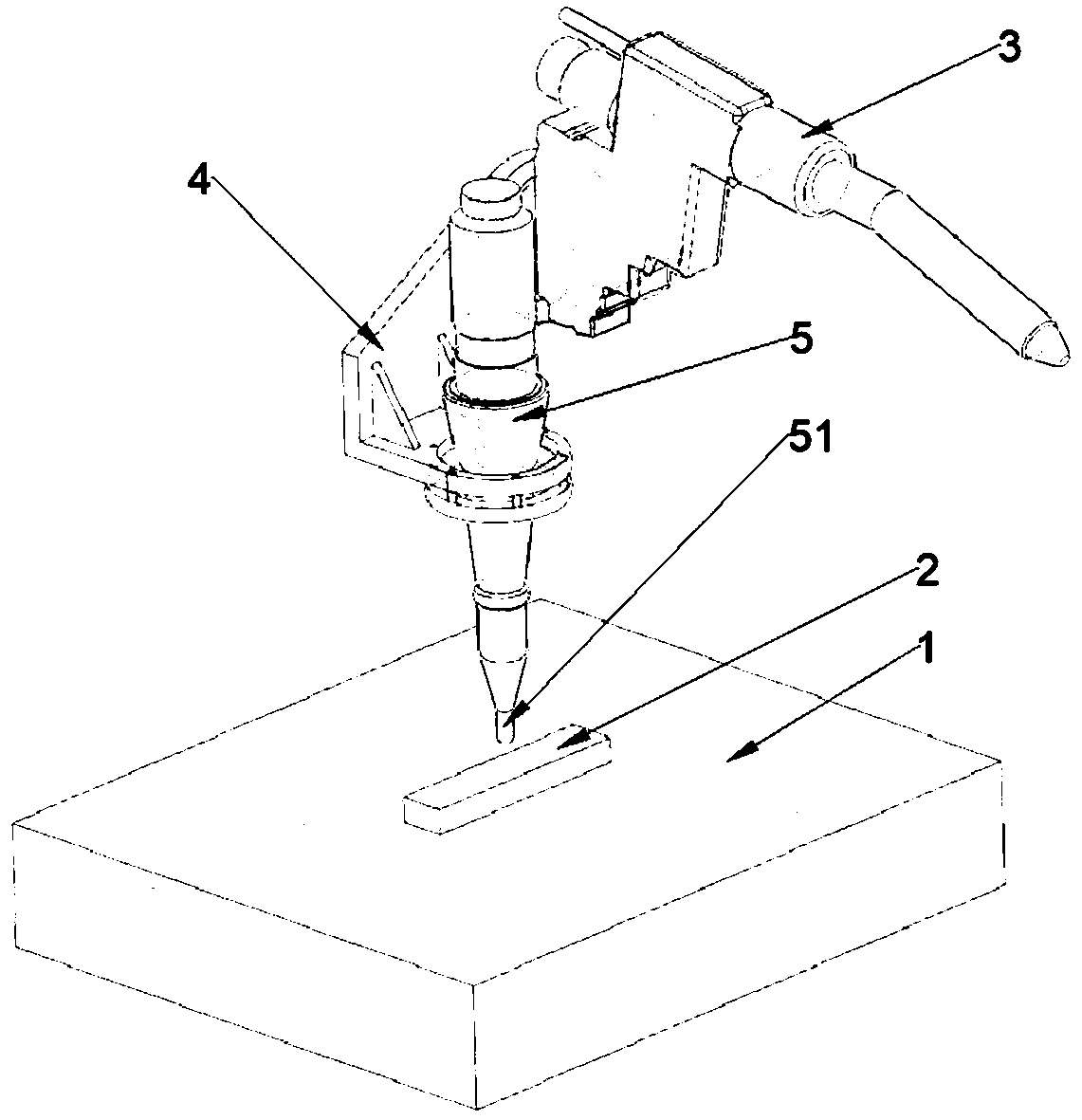

Embodiment 1

[0047] Select the thin-walled 5xxx series aluminum alloy for additive manufacturing as the additive material, that is, the additive manufacturing part 2, select a 6061 aluminum alloy substrate 1, choose a larger 6061 aluminum alloy substrate 1, and cut it into 6 substrates 1 of the same size, the substrate 1 The size is 150*150*18mm, additive manufacturing Figure 6 For thin-walled parts, adjust the position of the welding torch 3 so that the position of the thin-walled part is above the substrate 1, and set the welding torch to the above-mentioned optimal welding parameters for the material addition operation. After each layer of material is added, the robot controls the sandblasting nozzle 5 Sandblasting is performed on the surface of the current additive manufacturing part 2. During sandblasting, the robot controls the distance between the nozzle 5 and the additive material, and adjusts the angle of the nozzle so that the sandblasting direction and the normal direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com