Manufacturing method of supercapacitor

A technology of supercapacitor and manufacturing method, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of low production environment requirements, high production environment requirements, short production cycle, etc., and achieves low production environment requirements and is convenient for mass production. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

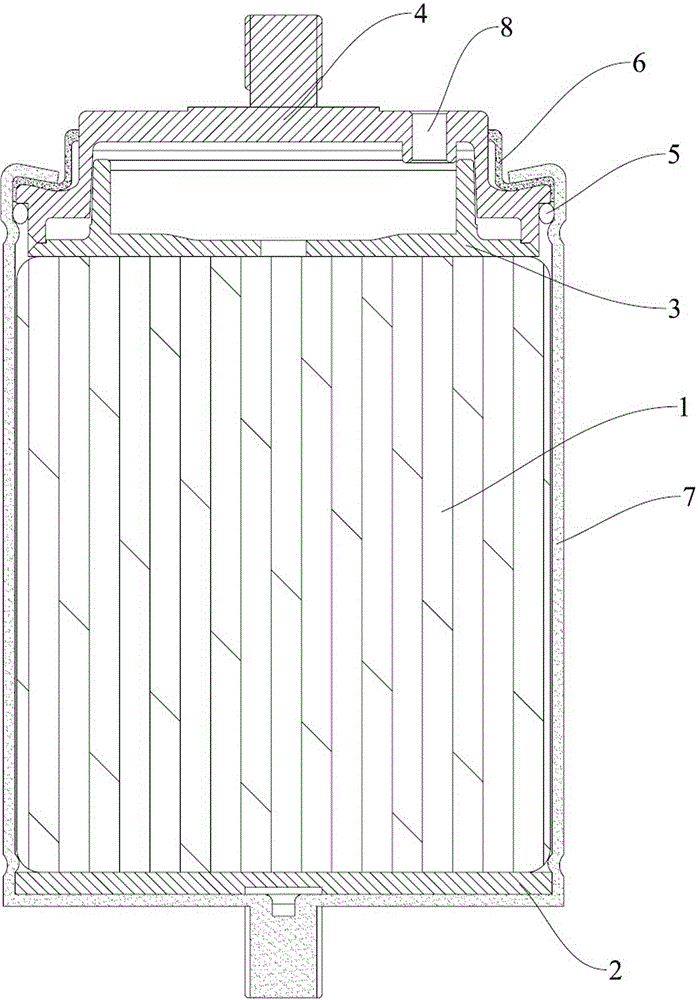

[0053] A method of manufacturing a supercapacitor, comprising the steps of:

[0054] (1) Preparation of electrode sheet and electrolytic paper: store the electrolytic paper and nickel foil electrode sheet at 45°C for 12 hours; the width of the nickel foil electrode sheet is 125mm, of which the carbon width is 110mm, and the blank width is 15mm; the width of the electrolyte 120mm;

[0055] (2) Winding: The ambient humidity of the winding is 13.8g of water per cubic meter of air. Under this humidity, nickel foil electrode sheets, electrolytic paper, nickel foil electrode sheets, and electrolytic paper are overlapped and wound together Form electrode core; the outer diameter of rolled electrode core is controlled within 58mm, and the length is controlled within 140mm;

[0056] (3) Welding: Sweep and compact both ends of the electrode core with a sweeper, and the length after compaction is about 125mm; weld the negative current collector on the lug of the compacted end of the ele...

Embodiment 2

[0064] A method of manufacturing a supercapacitor, comprising the steps of:

[0065] (1) Preparation of electrode sheet and electrolytic paper: store the electrolytic paper and copper foil electrode sheet at 50°C for 18 hours; the width of the copper foil electrode sheet is 125mm, of which the carbon width is 110mm, and the blank width is 15mm; the width of the electrolyte 120mm;

[0066] (2) Winding: The humidity of the environment where the winding is located contains 12g of water per cubic meter of air. Electrode core; the outer diameter of the rolled electrode core is controlled within 58mm, and the length is controlled within 140mm;

[0067] (3) Welding: Sweep and compact both ends of the electrode core with a sweeper, and the length after compaction is about 125mm; weld the negative current collector on the lug of the compacted end of the electrode core, and weld on the negative current collector Cover; Weld the positive current collector on the other end of the electr...

Embodiment 3

[0075] A method of manufacturing a supercapacitor, comprising the steps of:

[0076] (1) Preparation of electrode sheet and electrolytic paper: store electrolytic paper and aluminum foil electrode sheet at 55°C for 24 hours; the width of the aluminum foil electrode sheet is 125mm, of which the carbon width is 110mm, and the blank width is 15mm; the width of the electrolyte is 120mm;

[0077] (2) Winding: The humidity of the environment where the winding is located is 11g of water per cubic meter of air. Under this humidity, the aluminum foil electrode sheet, electrolytic paper, aluminum foil electrode sheet, and electrolytic paper are overlapped and wound together to form an electrode core. ;The outer diameter of the rolled electrode core is controlled within 58mm, and the length is controlled within 140mm;

[0078] (3) Welding: Sweep and compact both ends of the electrode core with a sweeper, and the length after compaction is about 125mm; weld the negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com