High piercing-resistance, cutting-resistant semi-steel engineering tyre and manufacturing method thereof

An engineering tire, cutting-resistant technology, used in tire parts, reinforcement layers of pneumatic tires, tire tread/tread pattern, etc. puncture and other problems, to achieve excellent puncture resistance, low rolling resistance, and increase the strength of the tire crown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

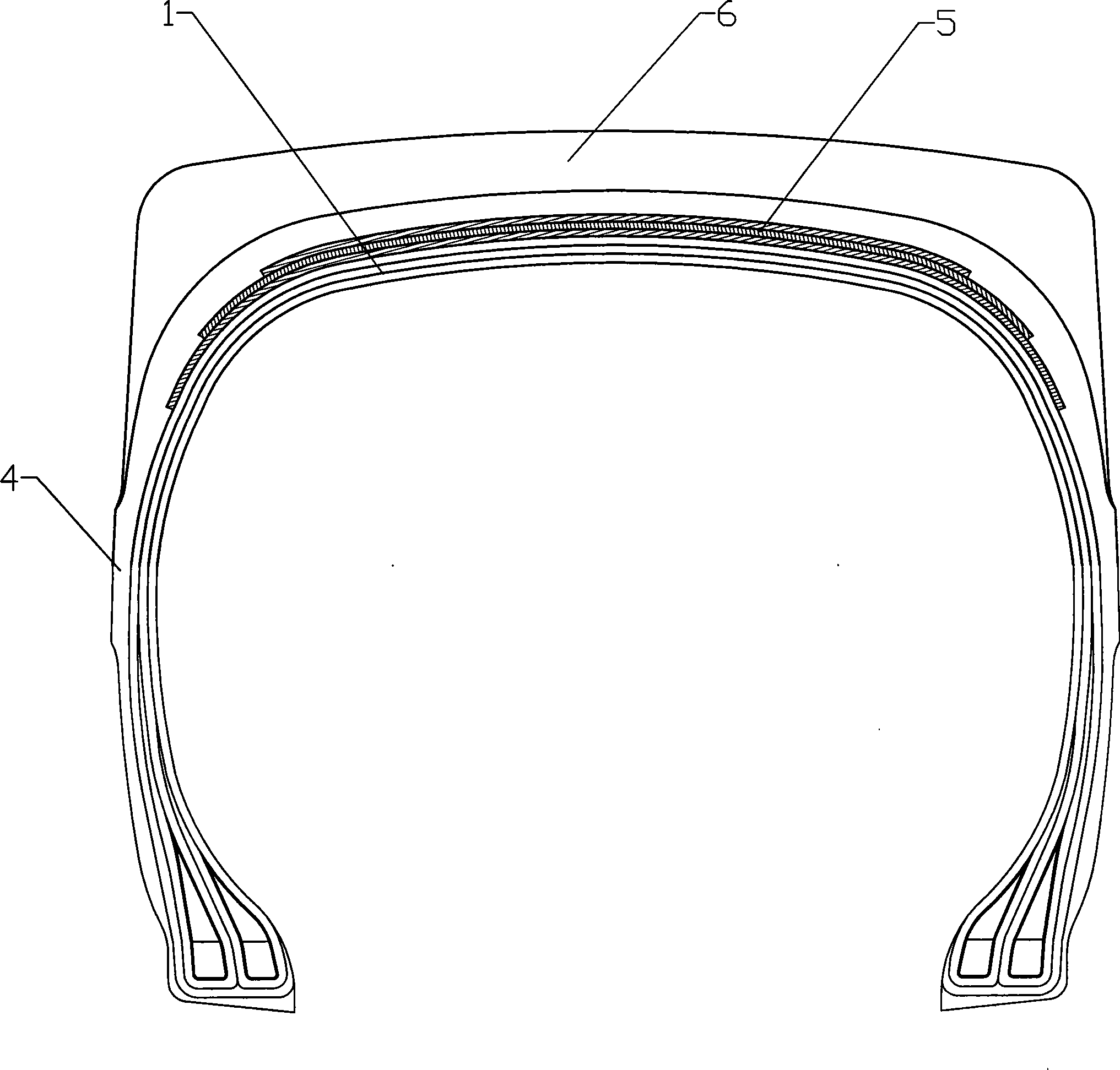

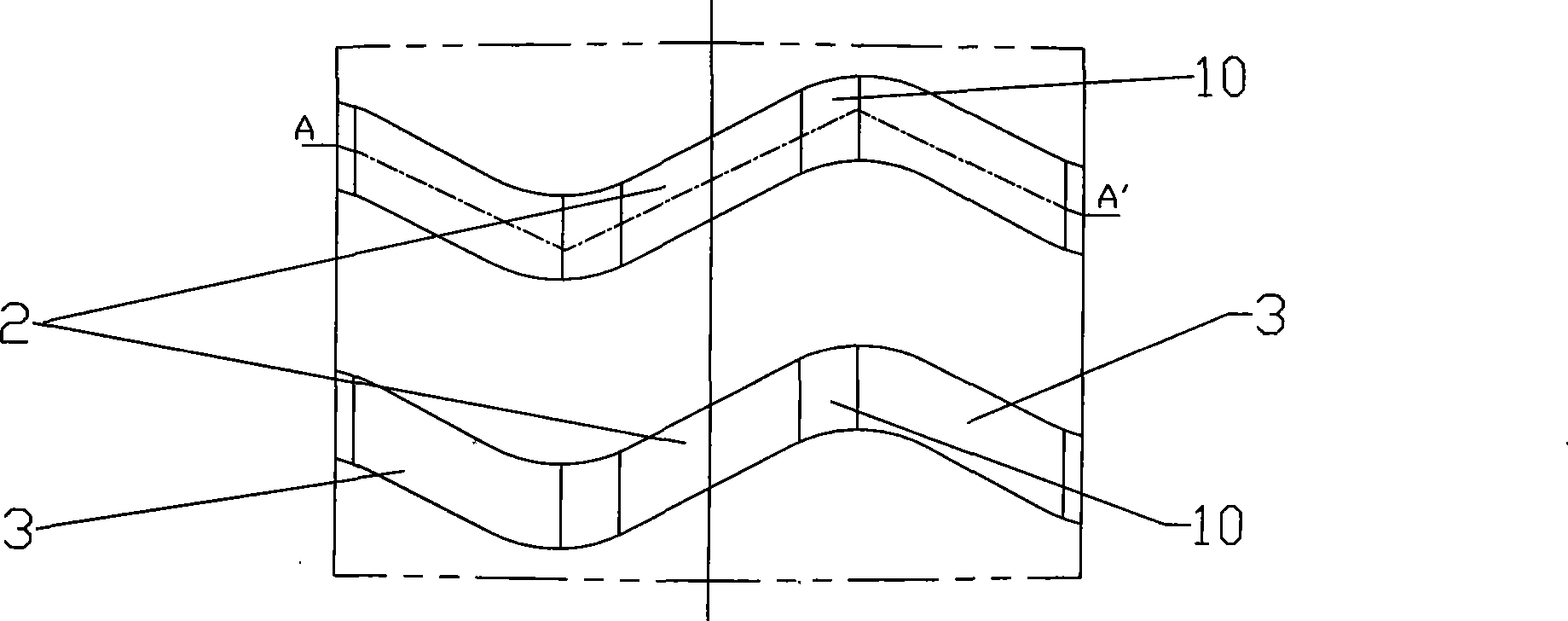

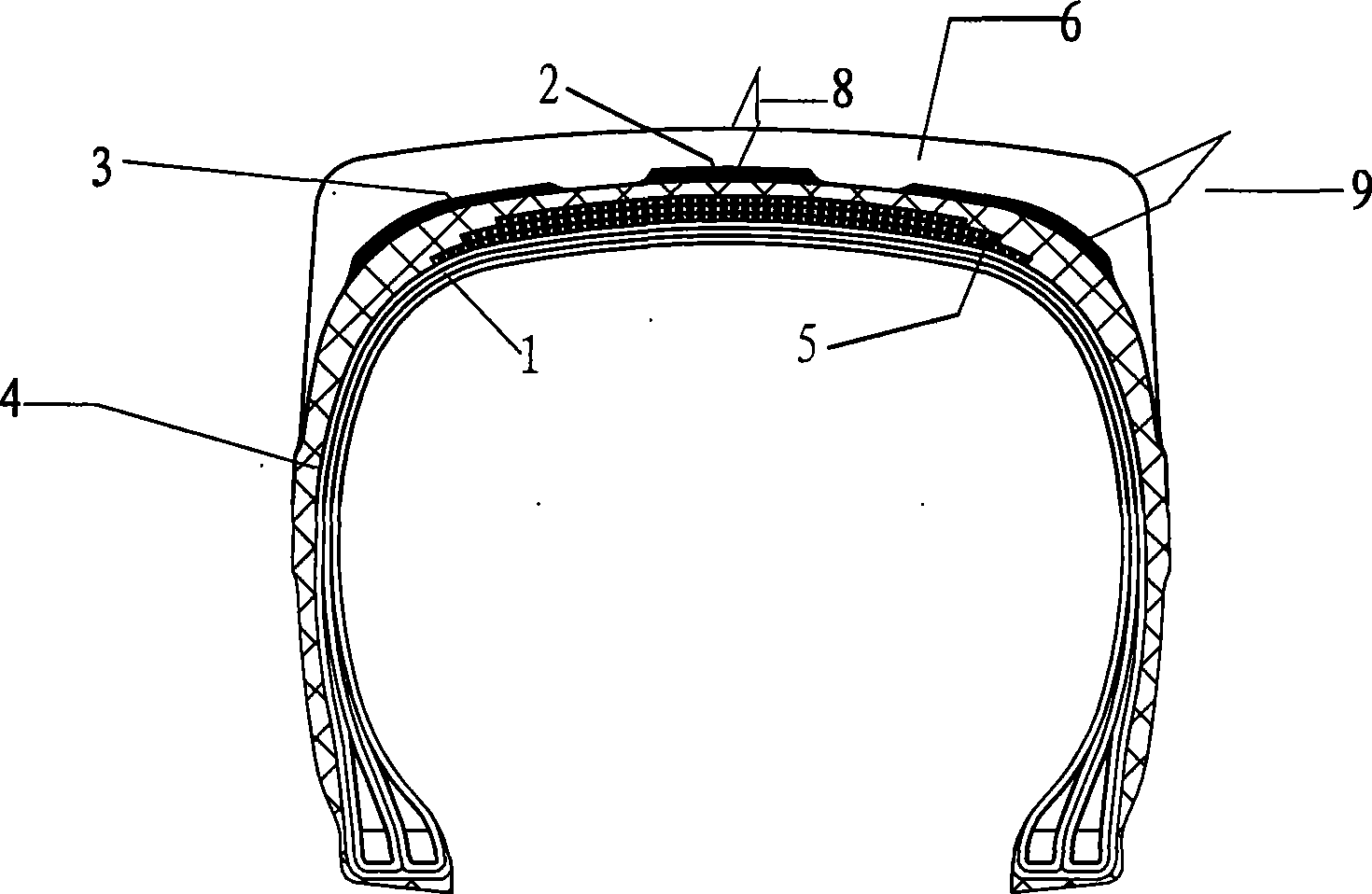

[0041] Embodiment 1, as attached figure 2 , 3 , 4, a high puncture-resistant, cut-resistant semi-steel engineering tire, including a carcass made of several layers of high-strength fiber cords, the outer side of the carcass 1 is fixed with a tire made of tread rubber. The tread includes a crown surface 6 and a sidewall 4, and a steel wire buffer layer 5 is provided between the tire crown surface 6 and the carcass 1, and the steel wire buffer layer 5 includes 2 to 10 layers of steel wire cords. The crown surface is provided with pattern grooves 10, and the bottom of the pattern grooves 10 is provided with a crown reinforcement platform 2, and the crown reinforcement platform 2 is arranged at the centerline position of the crown surface 6, between the crown surface 6 and The bottom of the pattern groove 10 at the connection part of the sidewall 4 is provided with a shoulder reinforcing platform 3, and the crown reinforcing platform 2 and the shoulder reinforcing platform 3 are...

Embodiment 2

[0054] Embodiment 2, as attached figure 2 , 3 , 4, a high puncture-resistant, cut-resistant semi-steel engineering tire, including a carcass made of several layers of high-strength fiber cords, the outer side of the carcass 1 is fixed with a tire made of tread rubber. The tread includes a crown surface 6 and a sidewall 4, and a steel wire buffer layer 5 is provided between the tire crown surface 6 and the carcass 1, and the steel wire buffer layer 5 includes 2 to 10 layers of steel wire cords. The crown surface is provided with pattern grooves 10, and the bottom of the pattern grooves 10 is provided with a crown reinforcement platform 2, and the crown reinforcement platform 2 is arranged at the centerline position of the crown surface 6, between the crown surface 6 and The bottom of the pattern groove 10 at the connection part of the sidewall 4 is provided with a shoulder reinforcing platform 3, and the crown reinforcing platform 2 and the shoulder reinforcing platform 3 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com