Machine tool liquid kinetic pressure center frame

A technology of hydrodynamic pressure and steady rest, which is applied in grinding machines, machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, etc., which can solve the problems of poor ability to absorb vibration of workpieces, easily damaged machined surface quality, and support accuracy No high problems, to achieve the effect of absorption and vibration, high support precision, and vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

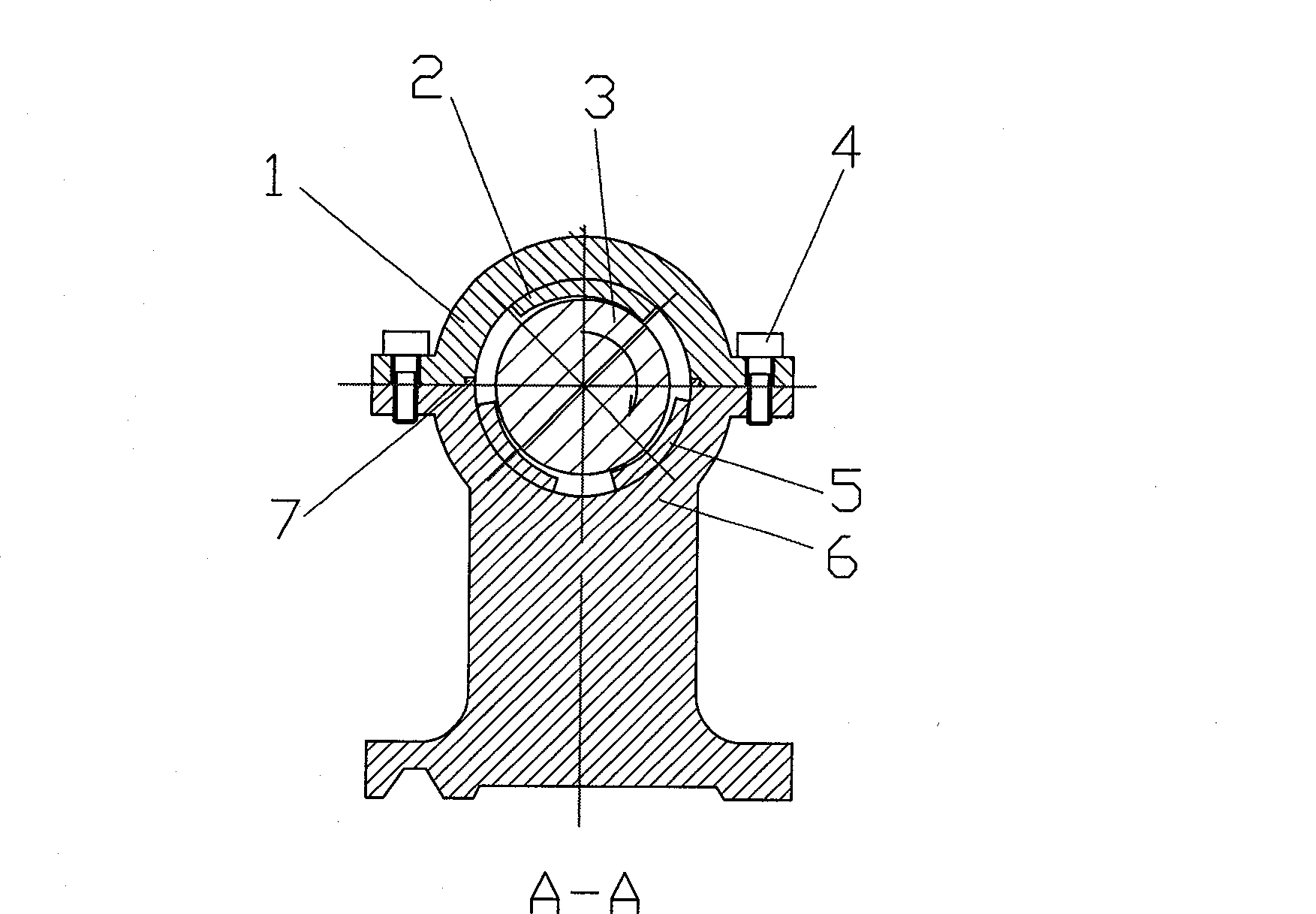

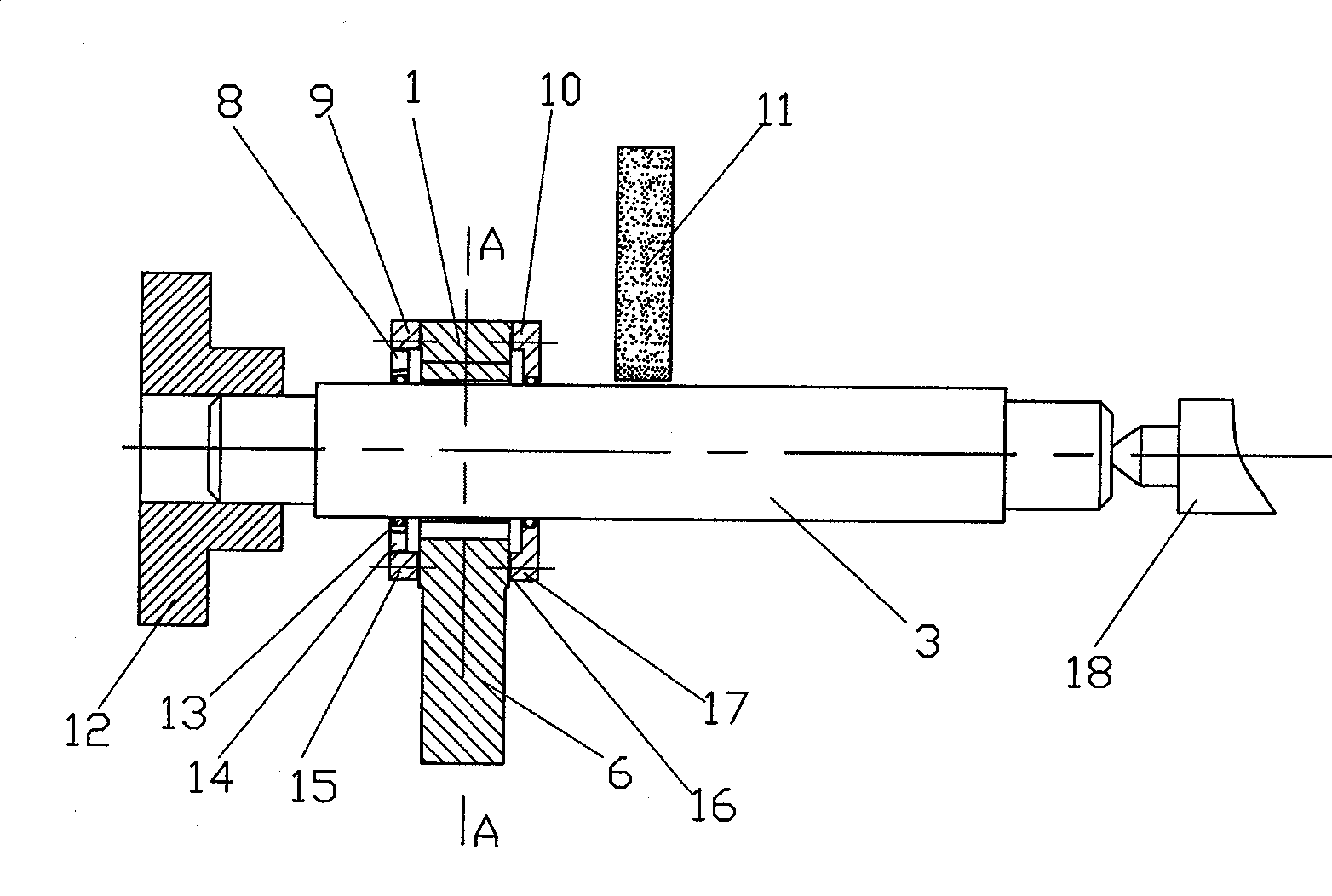

[0026] see figure 1 and figure 2 , the processed workpiece 3 is a high-precision spindle, one end of which is supported and clamped by the machine tool spindle chuck 12, and the other end is supported by the tailstock 18, and the surface of the processed workpiece 3 is ground by the emery wheel 11. Install the hydrodynamic center frame on the ground part of the processed workpiece 3, the machine tool hydrodynamic center frame includes an upper gland 1 and a center support 6 fixed by screws 4, and the upper gland 1 and the center A positioning notch 7 is provided between the supports 6 to ensure the positional accuracy after the two are assembled; The annular surface cooperates with the concave semicircular surface of the central support 6 to form a shaft machining hole; the upper bearing bush 2 is fixedly installed on the inner annular surface of the upper gland 1, and the concave semicircular surface of the central support 6 is evenly installed with Two lower bearing bushe...

Embodiment 2

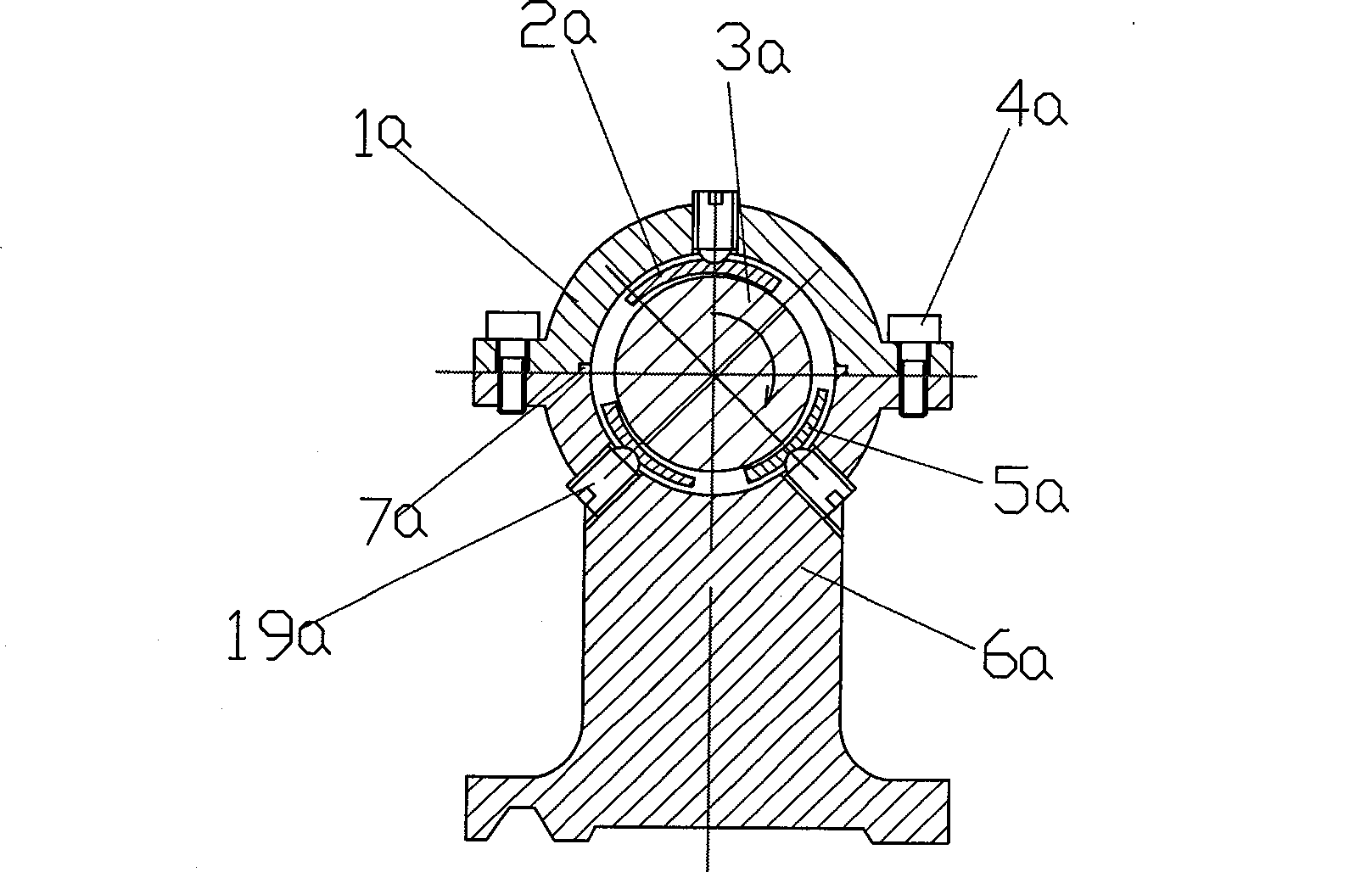

[0029] see image 3 and Figure 4 , the ball head adjustment screw 19a is installed radially on the upper gland 1a corresponding to the upper bearing bush 2a, and the ball head adjustment screw 19a is also installed on the center support 6a corresponding to the two lower bearing bushes 5a. The ball head is in the shape of a spherical segment; the backs of the upper bearing bush 2a and the two lower bearing bushes 5a corresponding to the ball head adjusting screw 19a are respectively provided with positioning circular sockets, and the positioning ball sockets on the backs of the upper bearing bush and the two lower bearing bushes are spherical pits; and The ball head adjusting screw 19a abuts on the positioning ball sockets on the back of the upper bearing bush 2a and the lower bearing bush 5a, and other structures are the same as in the first embodiment.

[0030] The upper bearing bush 2a and the lower bearing bush 5a can respectively swing around the ball head adjusting scre...

Embodiment 3

[0032] see Figure 5 and Figure 6 , the workpiece 3b to be processed is a large roll with a relatively large length and diameter, and the bending deformation caused by its own weight is the main factor affecting the machining accuracy. , to reduce the bending deformation caused by the workpiece's own weight. The ball head adjustment screw 19b is installed on the center support 6b, and the ball head of the ball head adjustment screw is in the shape of a spherical segment; the back of the bearing bush 5b corresponding to the ball head adjustment screw 19b is provided with a positioning ball socket, and the positioning ball socket on the back of the bearing pad is spherical pit; and the ball head adjustment screw 19b is supported on the positioning ball socket on the back of the bearing bush 5b, and other structures are the same as in Embodiment 1.

[0033] The bearing bush 5b can swing around the ball head adjustment screw 19b on its back to automatically adjust the gap. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com