Medical air compressor

An air compressor and chassis technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machinery, etc. Noise, improve heat dissipation efficiency, reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

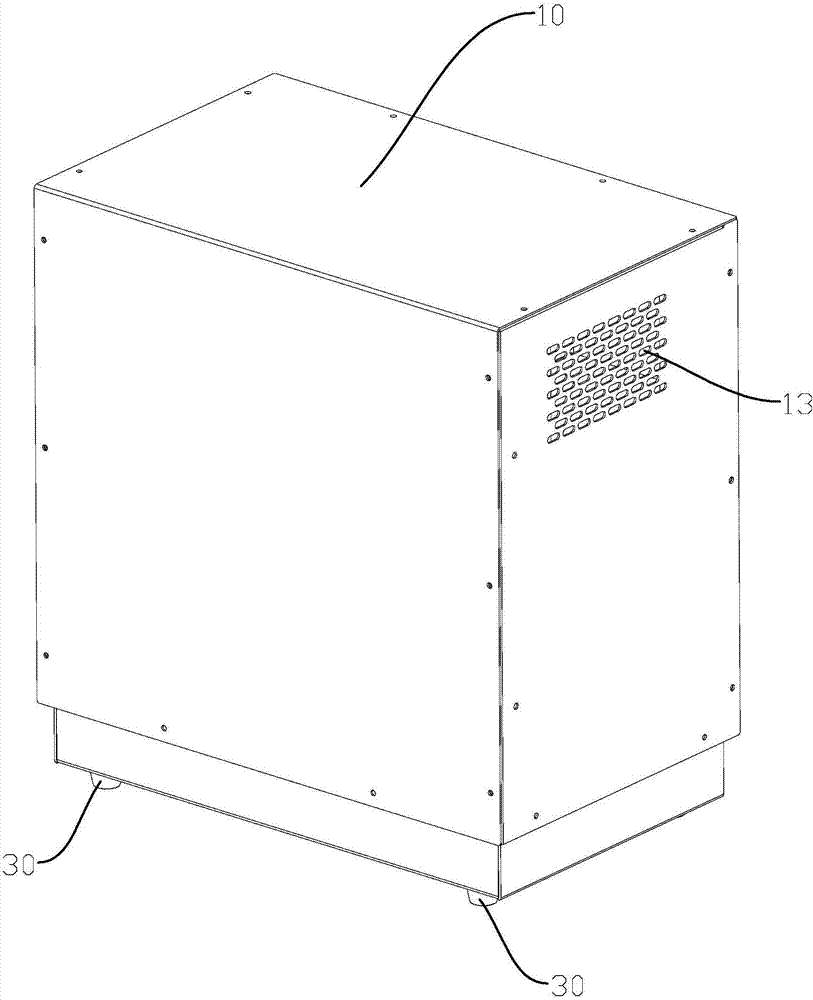

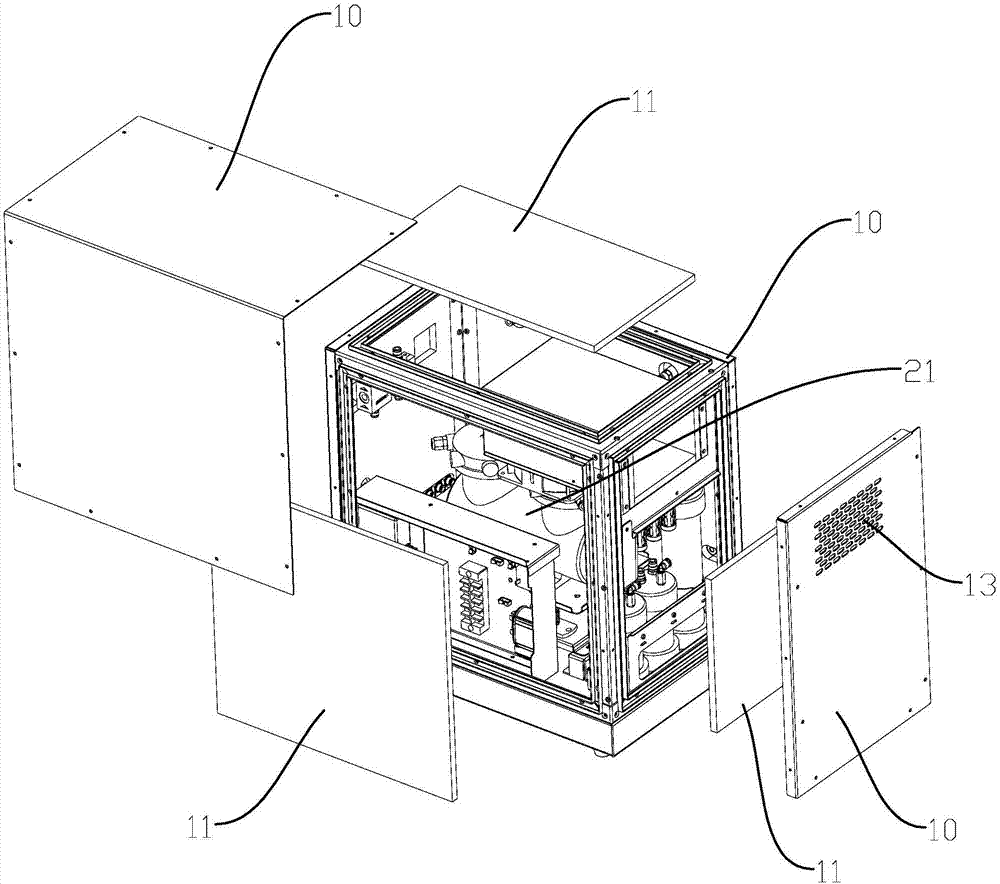

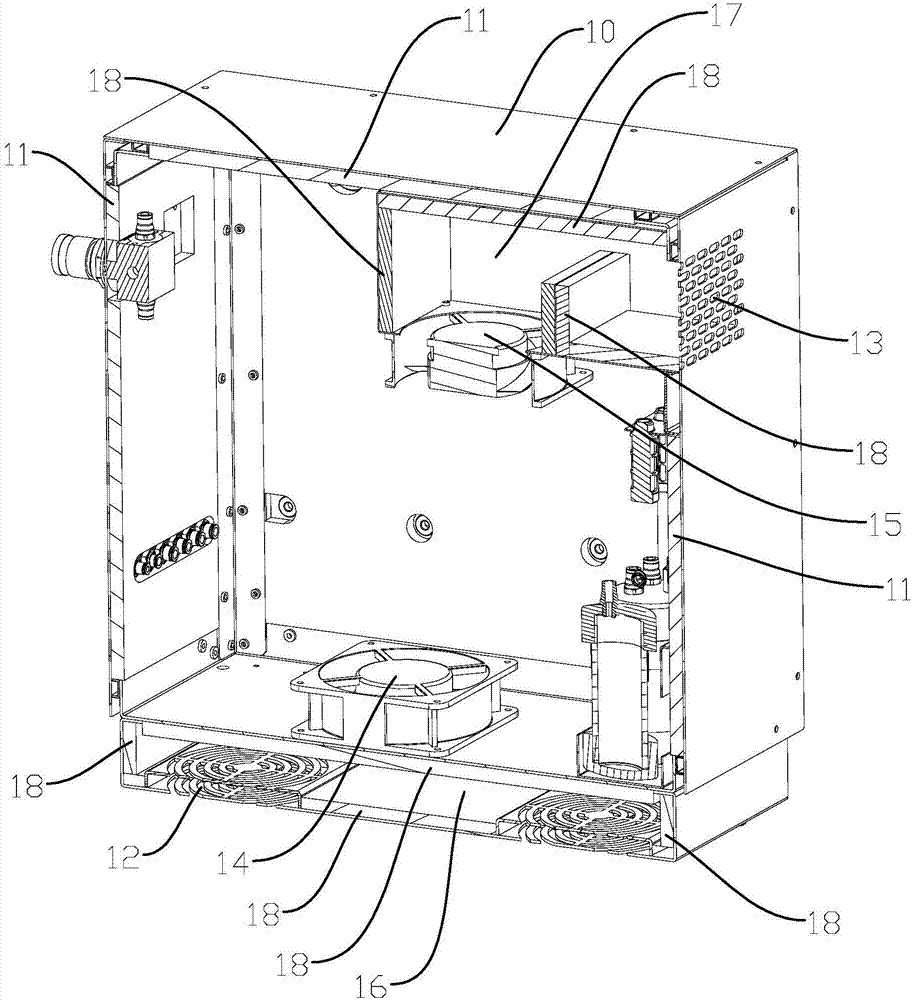

[0024] refer to Figure 1 to Figure 5 , a medical air compressor, comprising: a case 10, the inner wall of the case 10 is partially covered or completely covered with a first sound-absorbing member 11, and the outer wall of the case 10 is provided with an air inlet 12 and an air outlet 13 communicating with its inner cavity , the chassis 10 is provided with an airflow drive device for driving outside air from the air inlet 12 into the inner cavity of the chassis 10 and driving the air in the inner cavity of the chassis 10 to be discharged to the outside from the air outlet 13; the air compressor 21, through at least A vertical elastic member 22 is disposed in the case 10 . In the present invention, the air compressor 21 is arranged in the chassis 10 through the elastic member 22, and the elastic member 22 can absorb and slow down the vibration generated by the air compressor 21 during operation, thereby effectively reducing the noise generated by the air compressor 21 and redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com