Diaphragm suspension system and its used diaphragm suspension device

A film and suspended load technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increasing the weight of the backlight module, increasing the manufacturing cost, and affecting the weight of the final product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

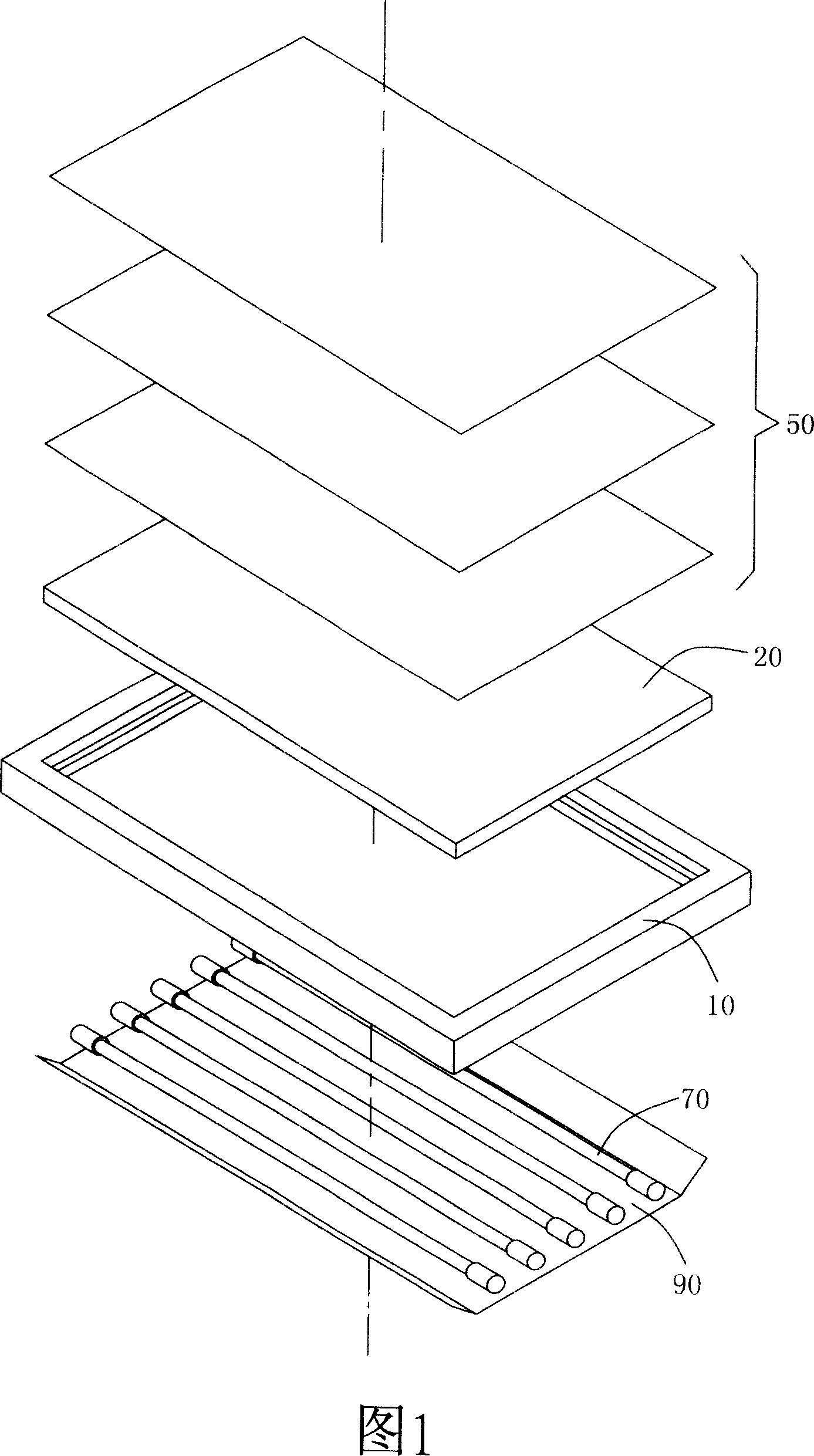

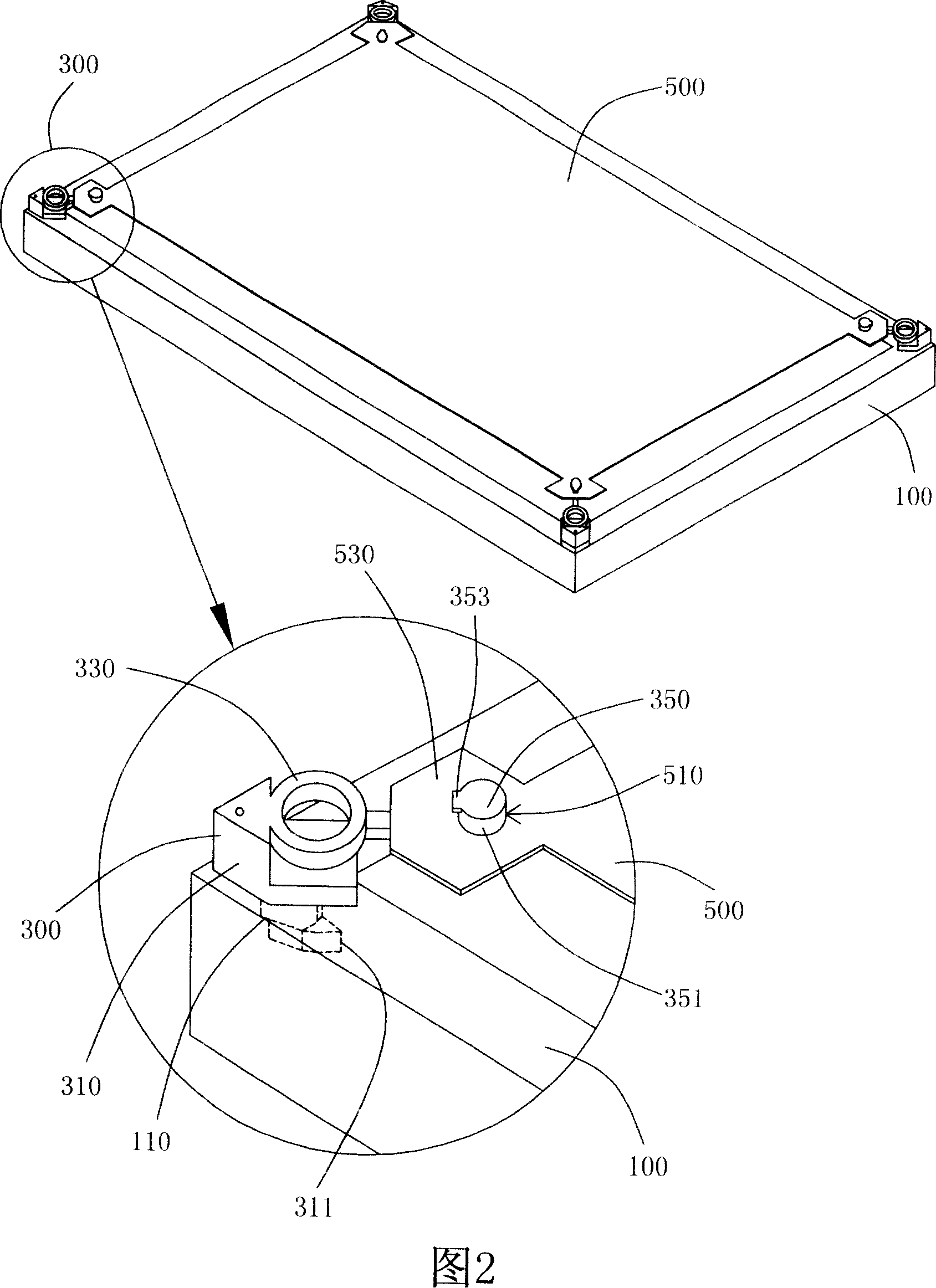

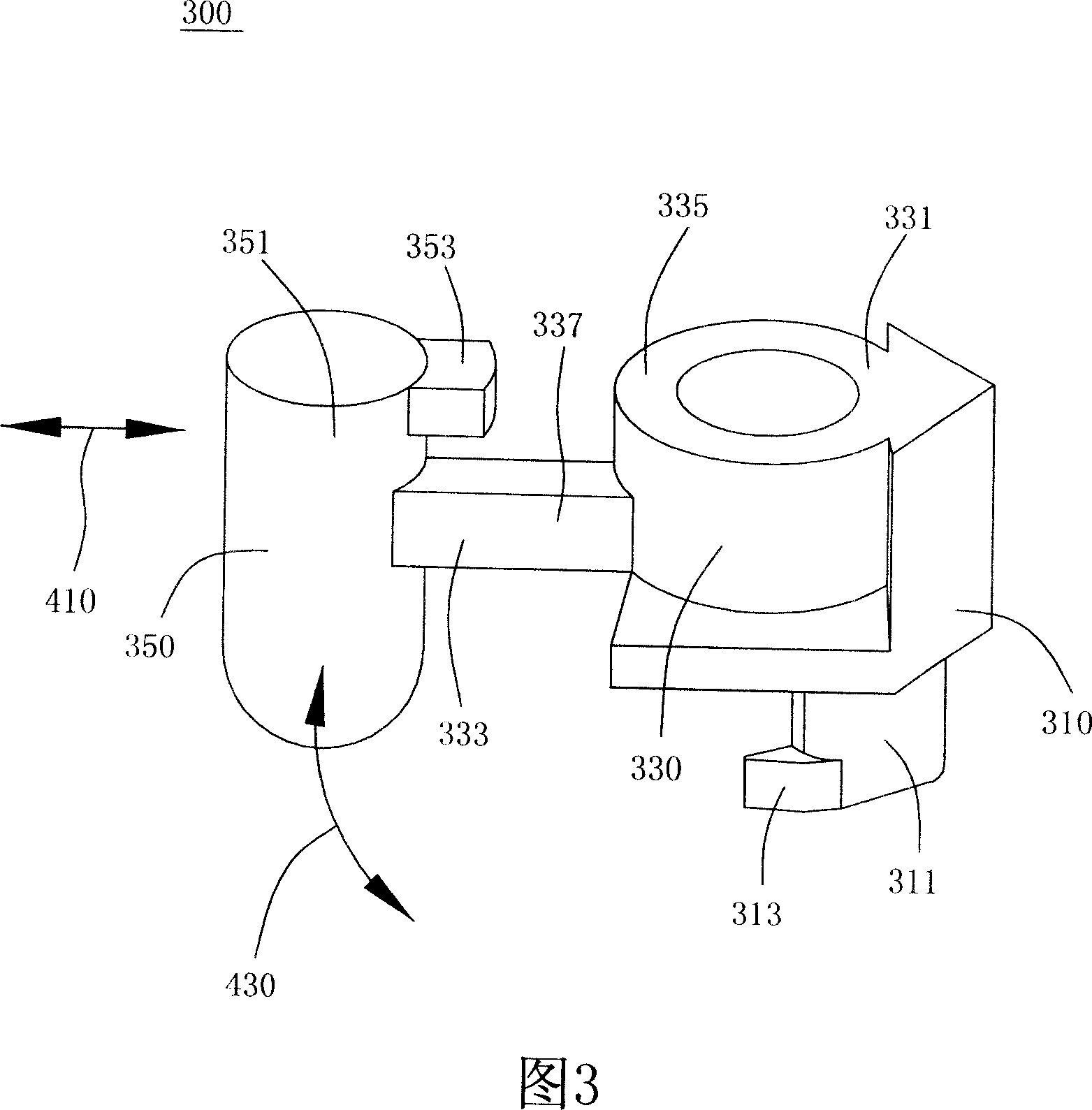

[0038] The invention provides a diaphragm suspension system and a diaphragm suspension device used therefor. The film preferably includes various optical films, such as a diffusion film, a brightness enhancement film, and a reflection film. In addition, the diaphragm may also include other sheet-shaped or plate-shaped optical elements, such as light guide plates. In a preferred embodiment, the film suspension system of the present invention is used for liquid crystal display devices and their backlight modules; however, in different embodiments, the backlight module containing the film suspension system of the present invention can also be used for computer keyboards, Mobile phone buttons, billboards and other devices that require flat light sources. Furthermore, the present invention also includes a liquid crystal display device using the membrane suspension system. In a preferred embodiment, the liquid crystal display device of the present invention includes a color liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com