Combined wood-face steel-core anti-theft door frame and mounting method

A combined anti-theft door technology, applied in the direction of anti-theft, window/door frame, window/door, etc., can solve the problems of complex and laborious installation, and achieve the effect of convenient installation, small error and good anti-prying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

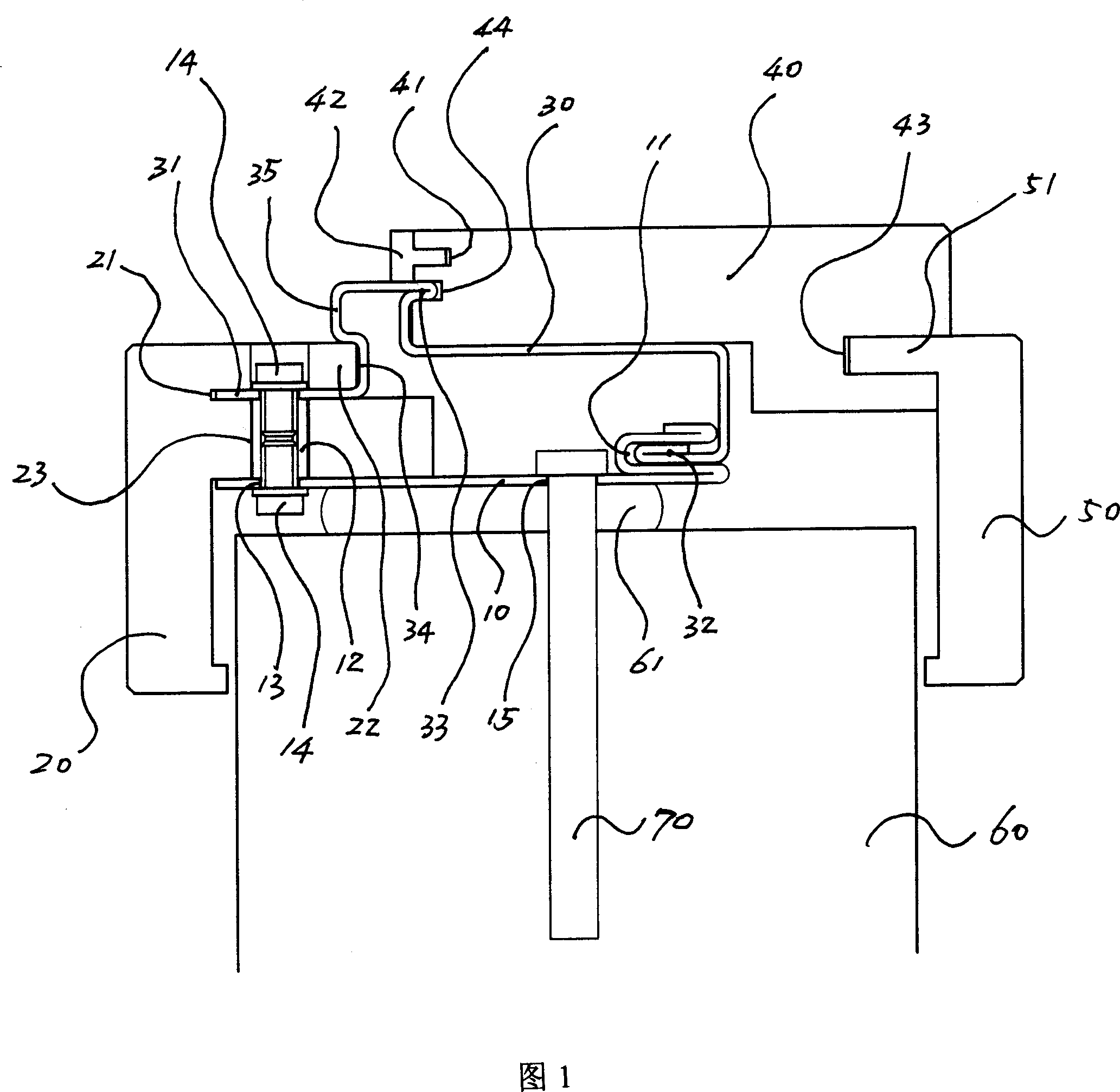

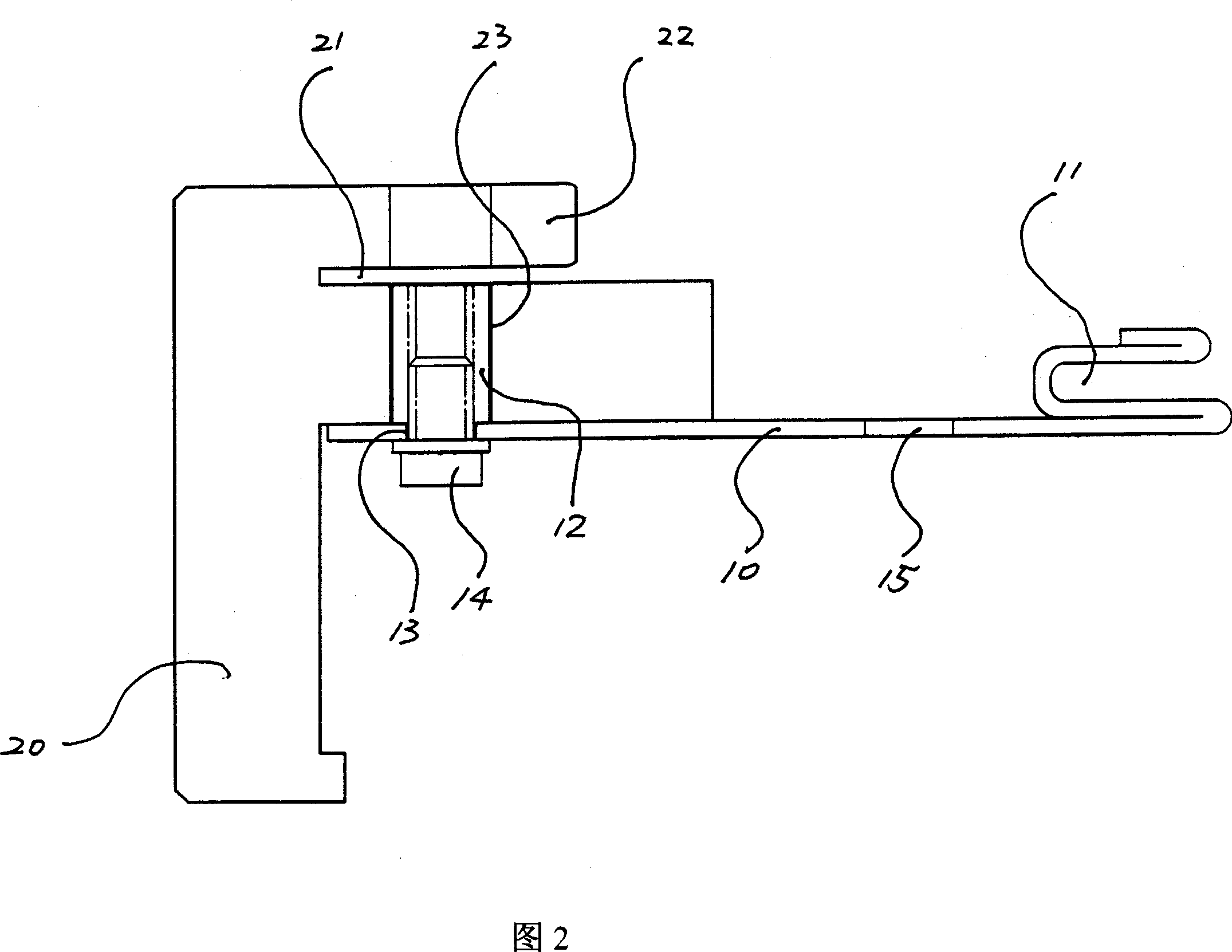

[0018] Embodiment 1: As shown in Figure 1, first connect the steel reference frame 10 and the wooden reference frame 20 together to form the main door frame; Connect together to form a secondary door frame; then pre-fix the main door frame in the door opening, and use styrofoam 61 to make it fixedly connected with the wall 60 of the door opening, and the expansion bolts 70 pass through the installation holes 15 to fix the main door frame on the wall of the door opening 60; the first positioning tenon 31 and the second positioning tenon 32 of the auxiliary door frame are respectively inserted into the first positioning groove 21 and the second positioning groove 11 of the main door frame, and the positioning tenon 22 on the main door frame is inserted into the positioning position on the auxiliary door frame In the slot 34 , a door stop line 35 is arranged above the positioning slot 34 . Install the bolt 14 on the positioning connecting column 12, so that the main door frame an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com