Dental tooth drill

A dental and rod technology, applied in the direction of dental drilling, dentistry, dental tools, etc., can solve the problems of insufficient flexibility, increased manufacturing cost, strong machinability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

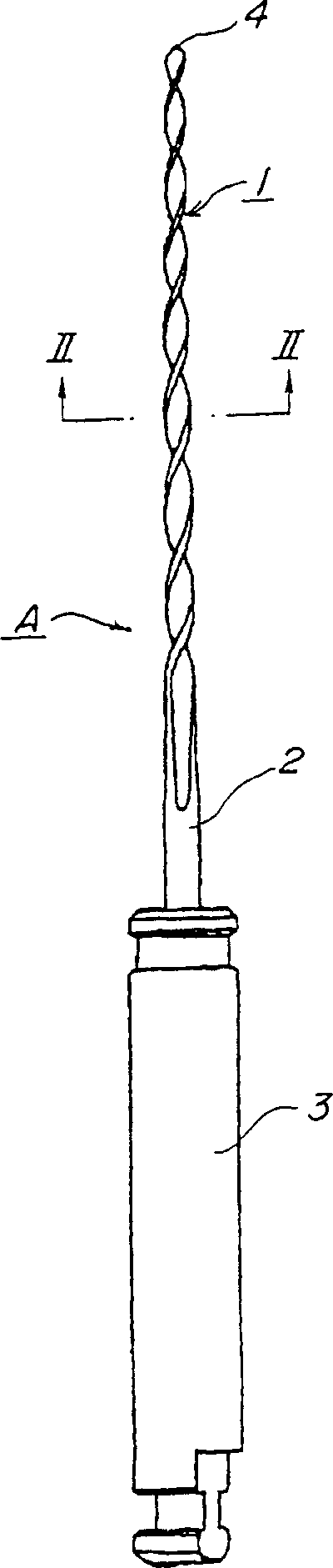

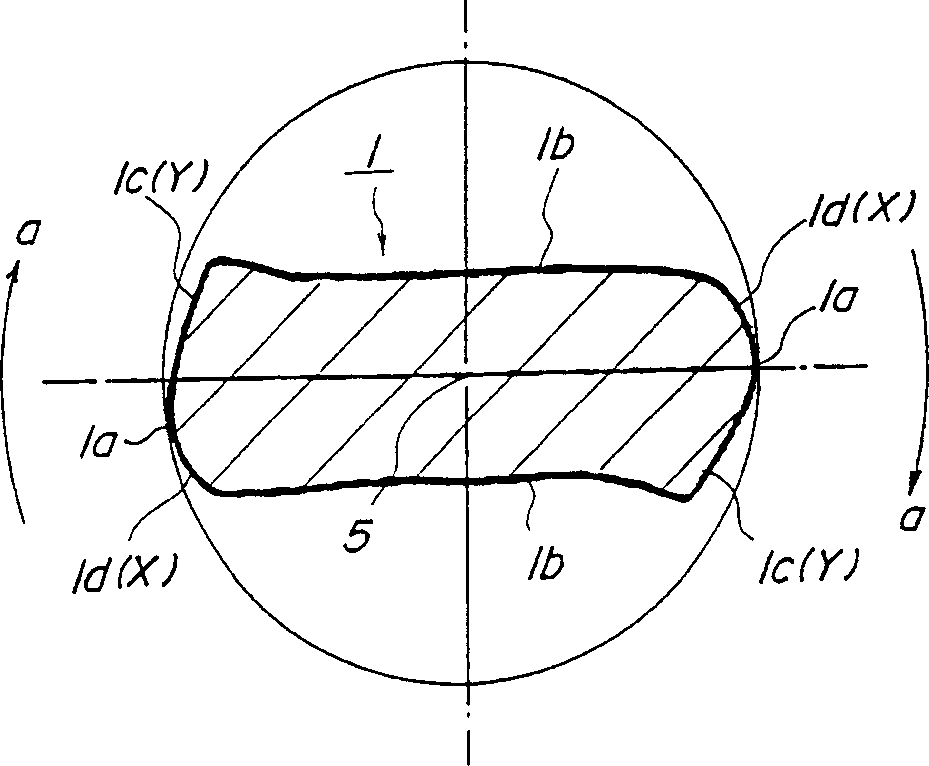

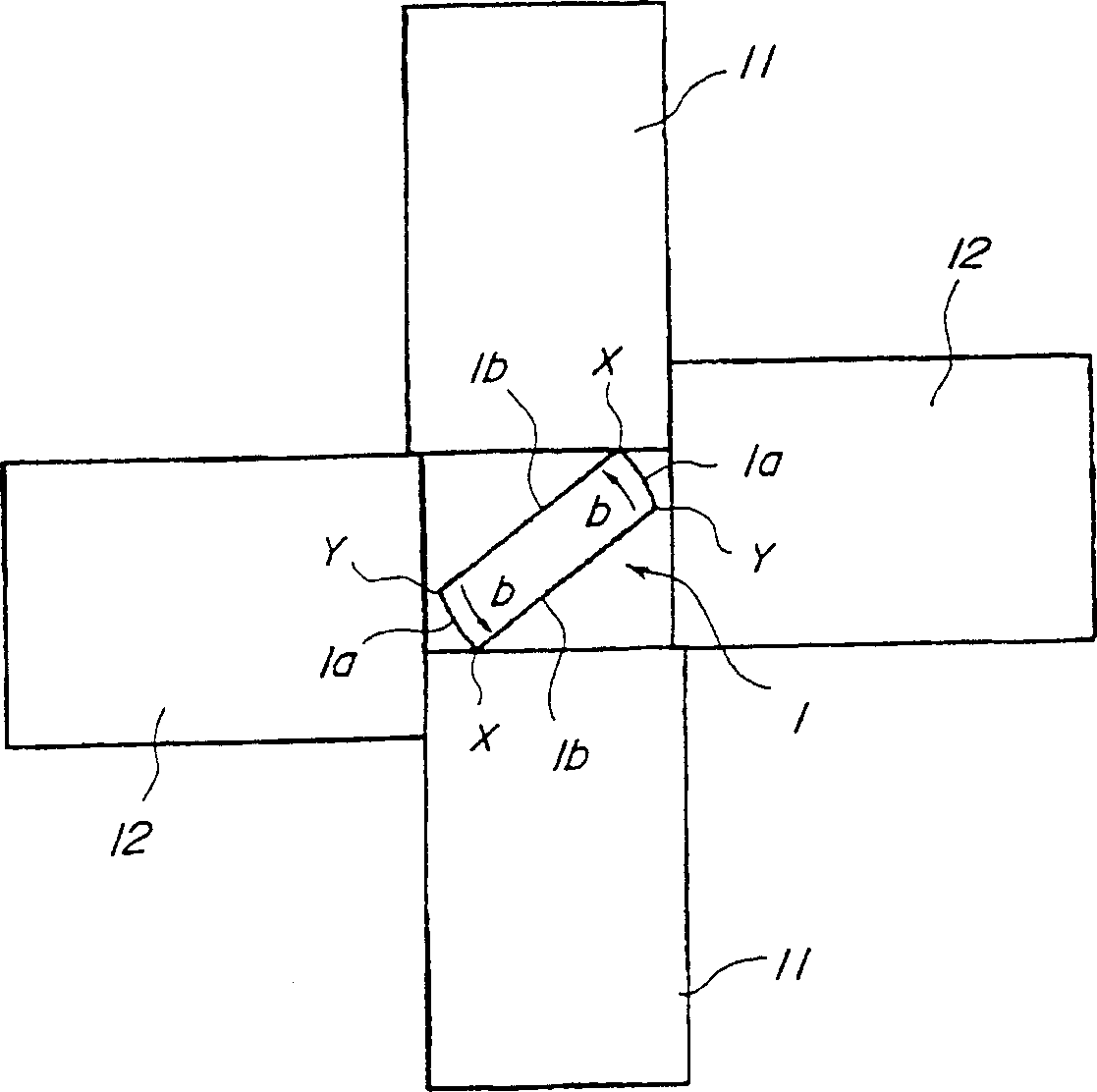

[0033] The preferred implementation forms of the above-mentioned dental drill are described below in conjunction with the accompanying drawings. figure 1 It is an explanatory diagram of the overall structure of the drill. figure 2 It is to describe the cross-sectional shape of the working part figure 1 II-II direction view. image 3 It is a schematic diagram illustrating an example of a twist forming device used when forming a working part. Fig. 4 is an explanatory diagram of a cross-sectional shape of an intermediate material. Fig. 5 is a cross-sectional view of a working portion formed by twisting an intermediate material having the cross-sectional shape of Fig. 4 . Fig. 6 shows the result of forming a root canal with the drill of this embodiment, the NiTi file and the engine drill. Figure 7 It is to compare the time required for root canal formation with a plurality of test pieces of the size number No. 20 (tip diameter 0.2 mm) of the present invention, NiTi file and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com