Connecting structure of red mud storage yard anti-seepage film and concrete column and construction method

A technology for concrete columns and connecting structures, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as health hazards, environmental pollution, leakage of red mud attached liquid, etc., to reduce environmental and health problems, easy to operate, The effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

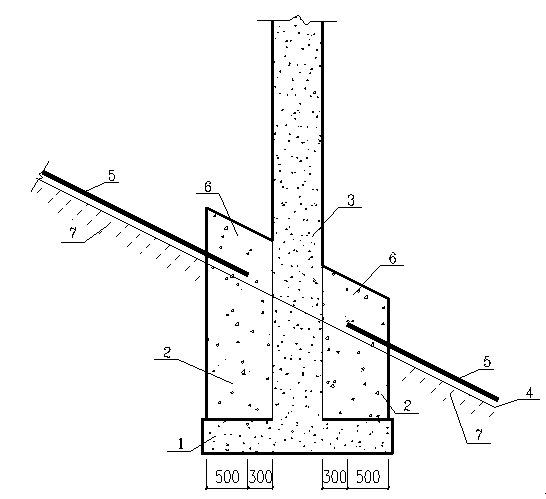

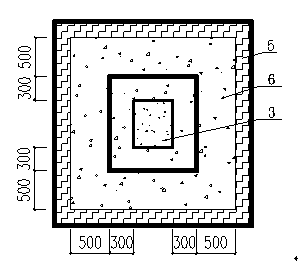

[0023] Embodiment of the present invention: the connection structure between the red mud stockyard anti-seepage membrane and the concrete column of the present invention is: a film-pressing platform 2 is set on the column foundation 1 and below the field level line 4 of the stockyard foundation 7, and the film is pressed The upper end surface line of the platform 2 is consistent with the field level line 4, and the micro-expansion concrete layer 6 is arranged on the upper end surface of the pressure-film platform 2, and the pressure-film platform 2 and the micro-expansion concrete layer 6 respectively surround the column 3 from bottom to top; the anti-seepage membrane 5 is laid on the field level 4 and extends into the cast micro-expansion concrete layer 6 to form a complete anti-seepage body.

[0024] The construction method of the connection structure of the anti-seepage membrane of the red mud stockyard and the concrete column of the present invention is constructed accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com