Back irradiation arsenic indium table face line array or face array detector chip and its making technology

A detector chip, InGaAs technology, applied in sustainable manufacturing/processing, semiconductor devices, final product manufacturing, etc., can solve the problem of device responsivity and quantum efficiency reduction, limit the performance of InGaAs detectors, and limit the uniformity of devices Improve the performance and other issues to achieve the effect of reducing the surface charge density and interface state density, improving the responsivity and detection rate, and reducing the dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

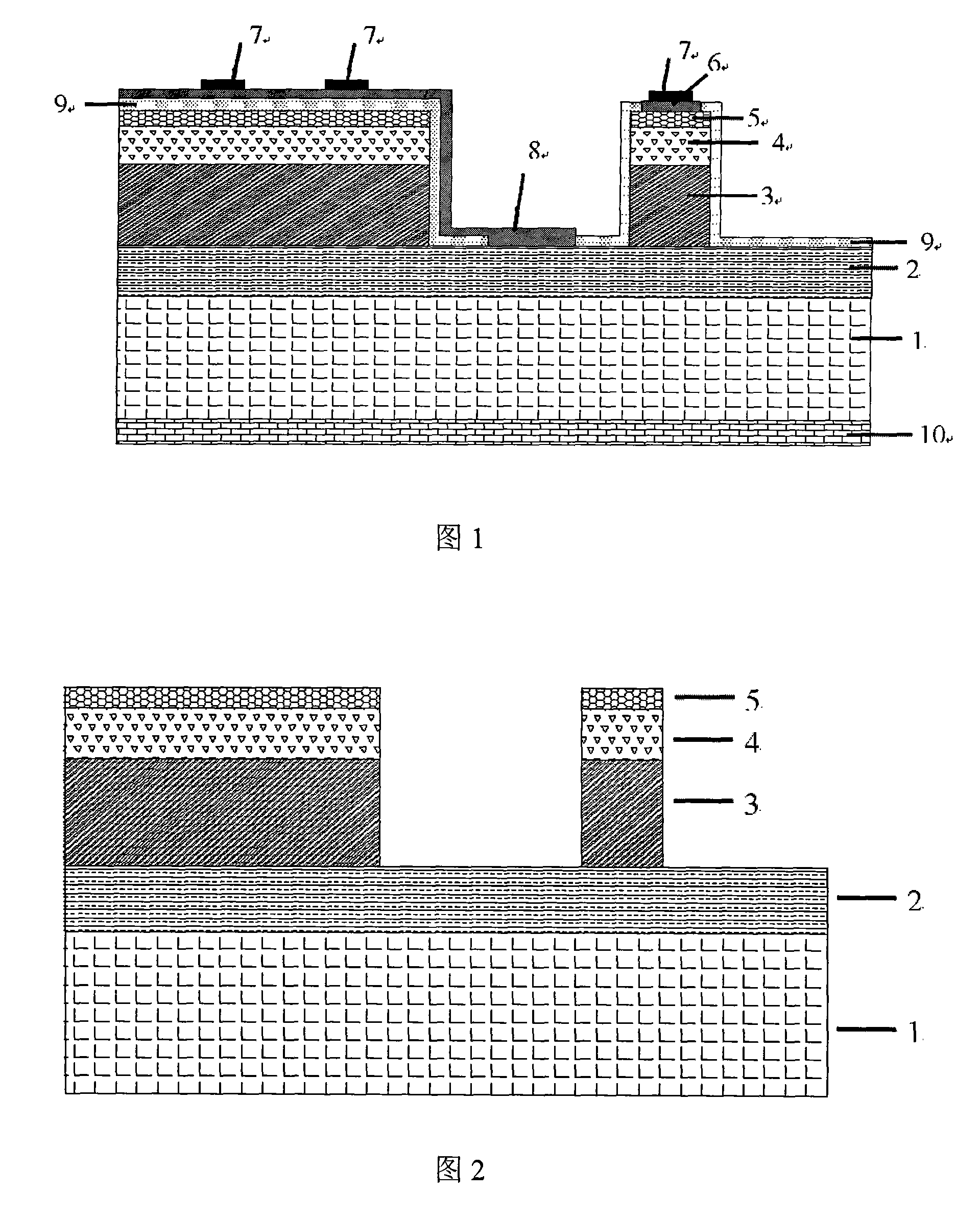

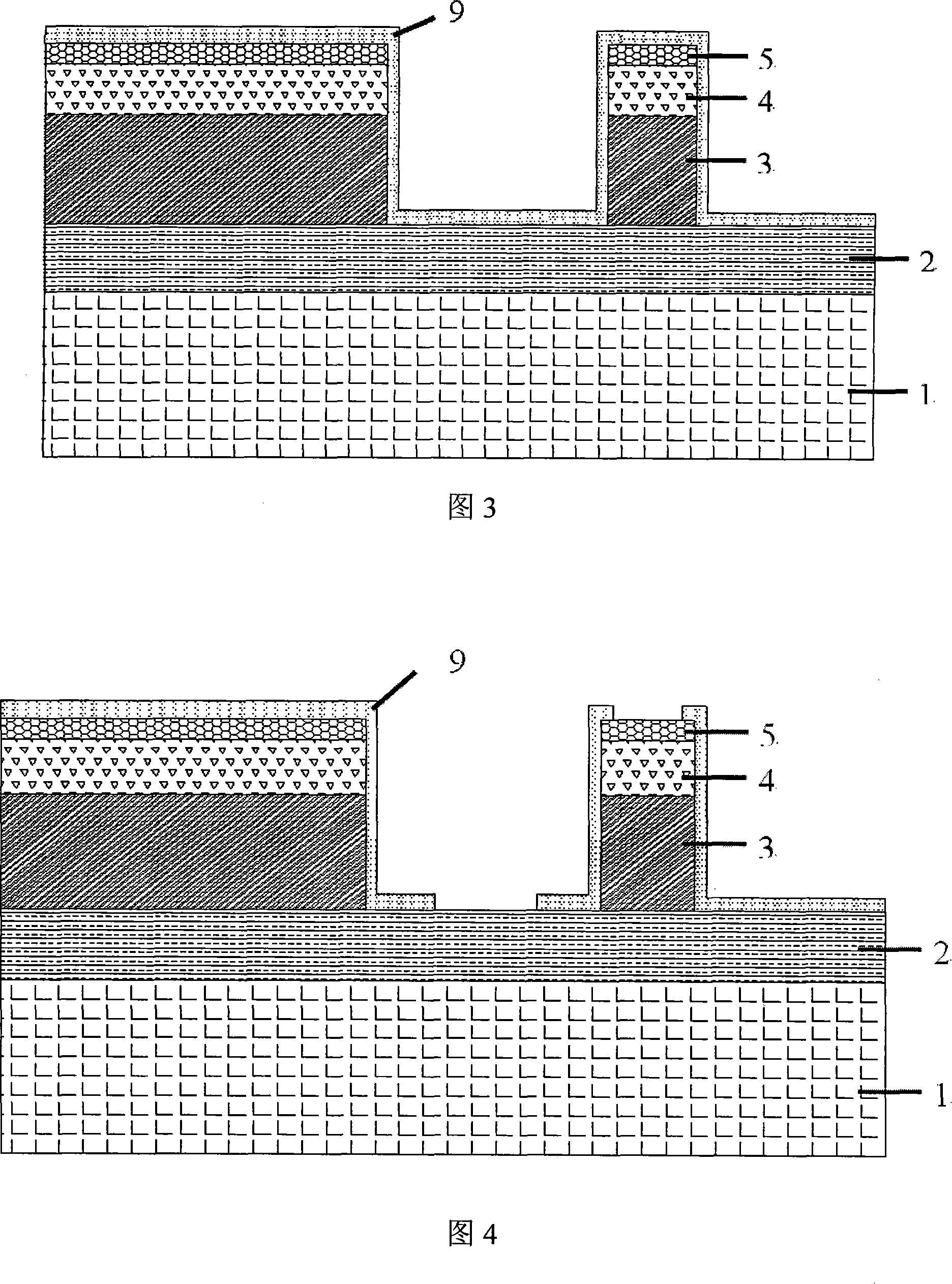

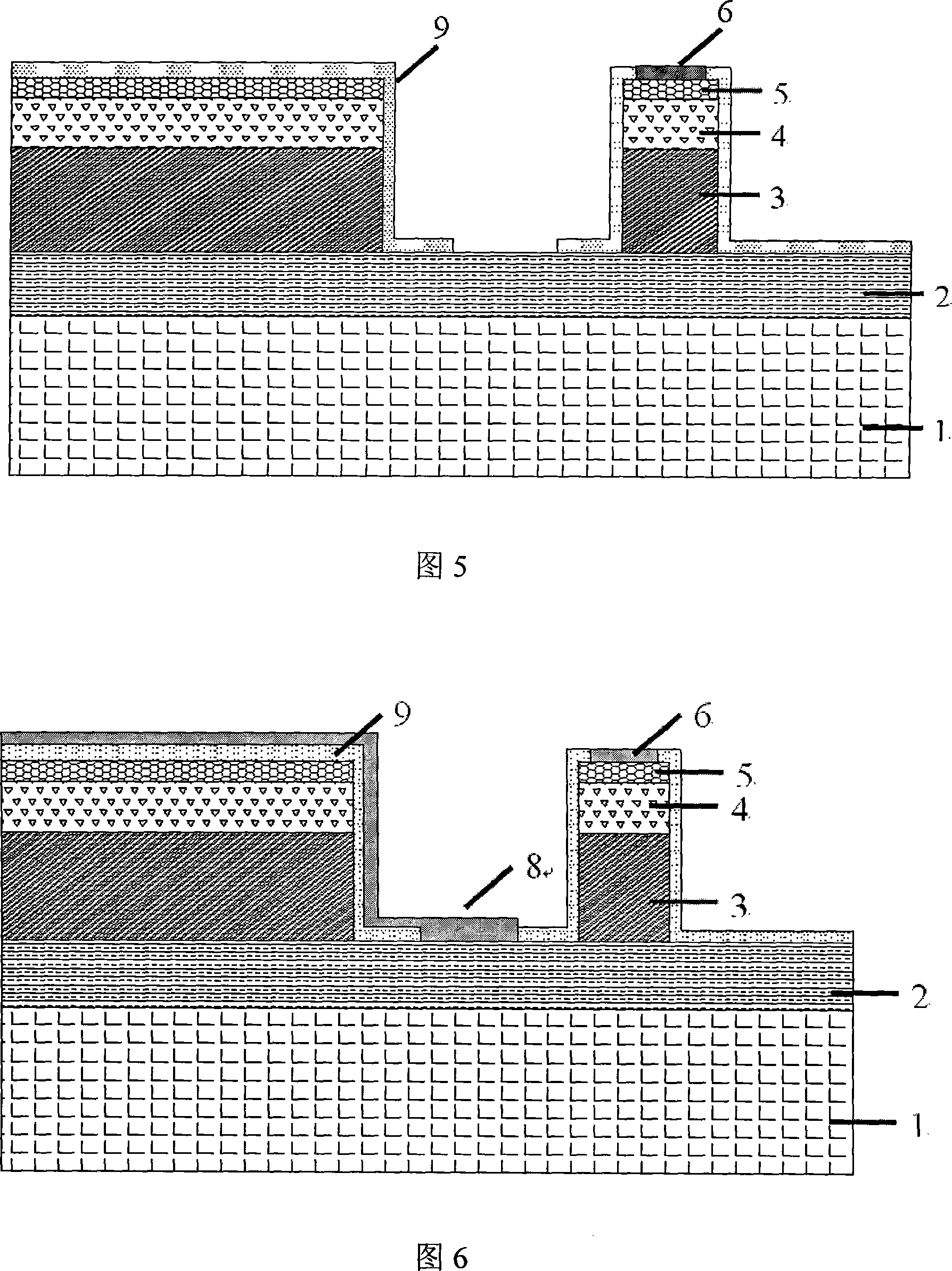

[0024] As shown in Figure 1, the epitaxial wafer used in the detector of this embodiment is an N-type InP layer 2 with a thickness of 1 μm grown sequentially on a semi-insulating InP substrate 1 with a thickness of 350 μm by MBE technology, and the carrier concentration is greater than 2 ×10 18 cm -3 ; In thickness of 1.1 μm to 1.5 μm 0.53 Ga 0.47 As absorption layer 3, the carrier concentration is 5×10 16 cm -3 ; P-type InP cap layer 4 with a thickness of 0.5 μm, the carrier concentration is greater than 2×10 18 cm -3 ; The uppermost layer grows a p-InGaAs layer 5 with a thickness of 20nm and a carrier concentration of 2×10 18 cm -3 . On the epitaxial wafer, the linear p-InGaAs / p-InP / i-InGaAs micro-mesas are formed by etching, and there is a Ti / Pt / Au electrode region 6 in ohmic contact with p-InGaAs on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com