Steel bar counting method

A counting method and steel bar technology, applied in calculation, image data processing, instruments, etc., can solve the problems of large counting error and inability to use a large number of stably, and achieve fast and accurate analysis and strong anti-environmental interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

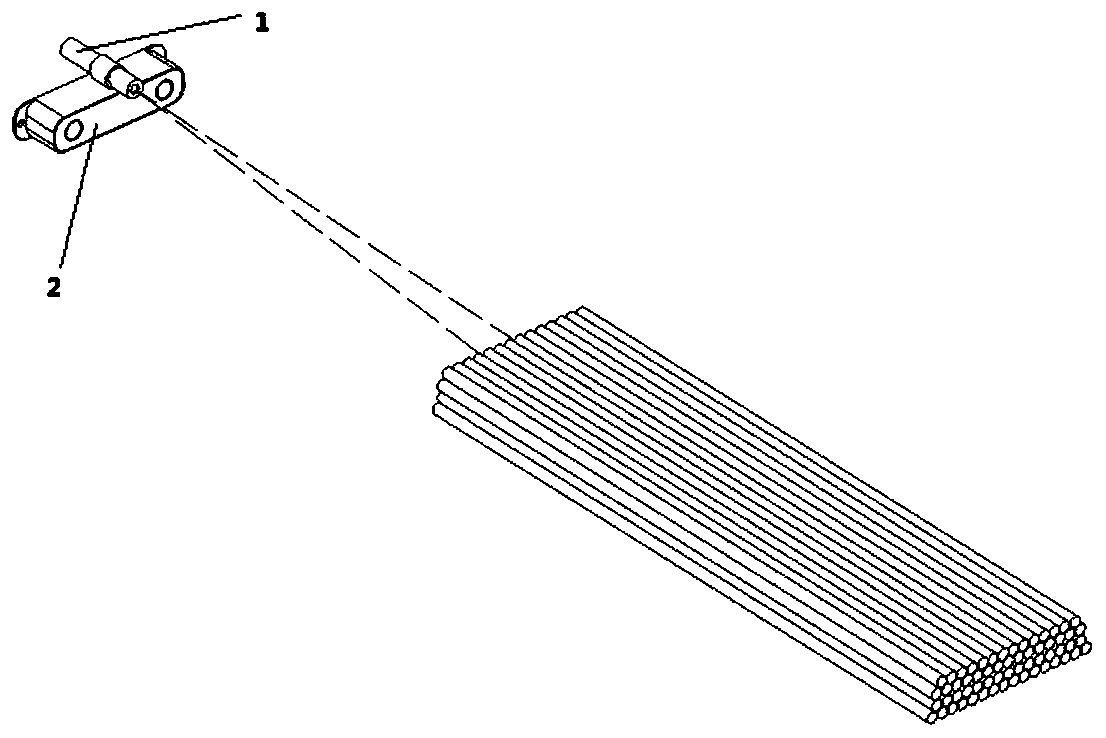

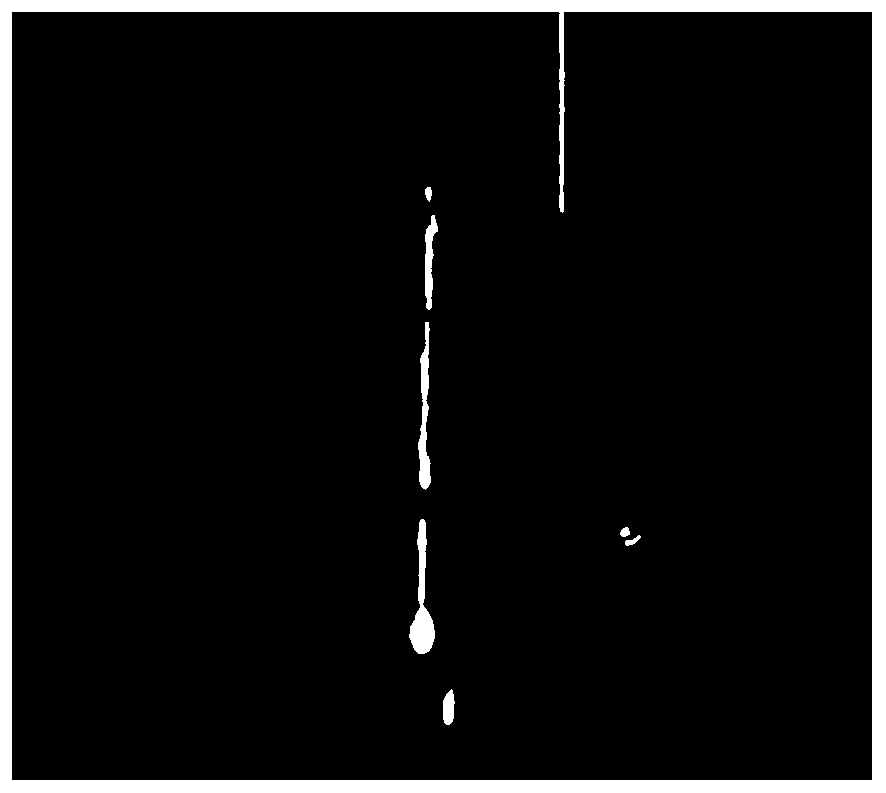

[0018] see Figure 1-3 , the embodiment of the present invention specifically includes the following steps:

[0019] (1) Stereo calibration of the binocular camera;

[0020] (2) The line laser emitted by the control line laser transmitter is projected to a certain place on the end face of the steel bar;

[0021] (3) Obtain the time-stamped left image and right image of the steel bar end face respectively by the left camera and the right camera of the binocular camera;

[0022] (4) Stereoscopic correction is carried out to the acquired left image and right image, so that the corrected left image and right image line are aligned;

[0023] (5) Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com