High-rigidity joint torque sensor

A joint torque and sensor technology, applied in the field of torque measurement, can solve problems such as poor output signal quality, and achieve the effect of improving control accuracy, good quality, high radial force and axial force interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

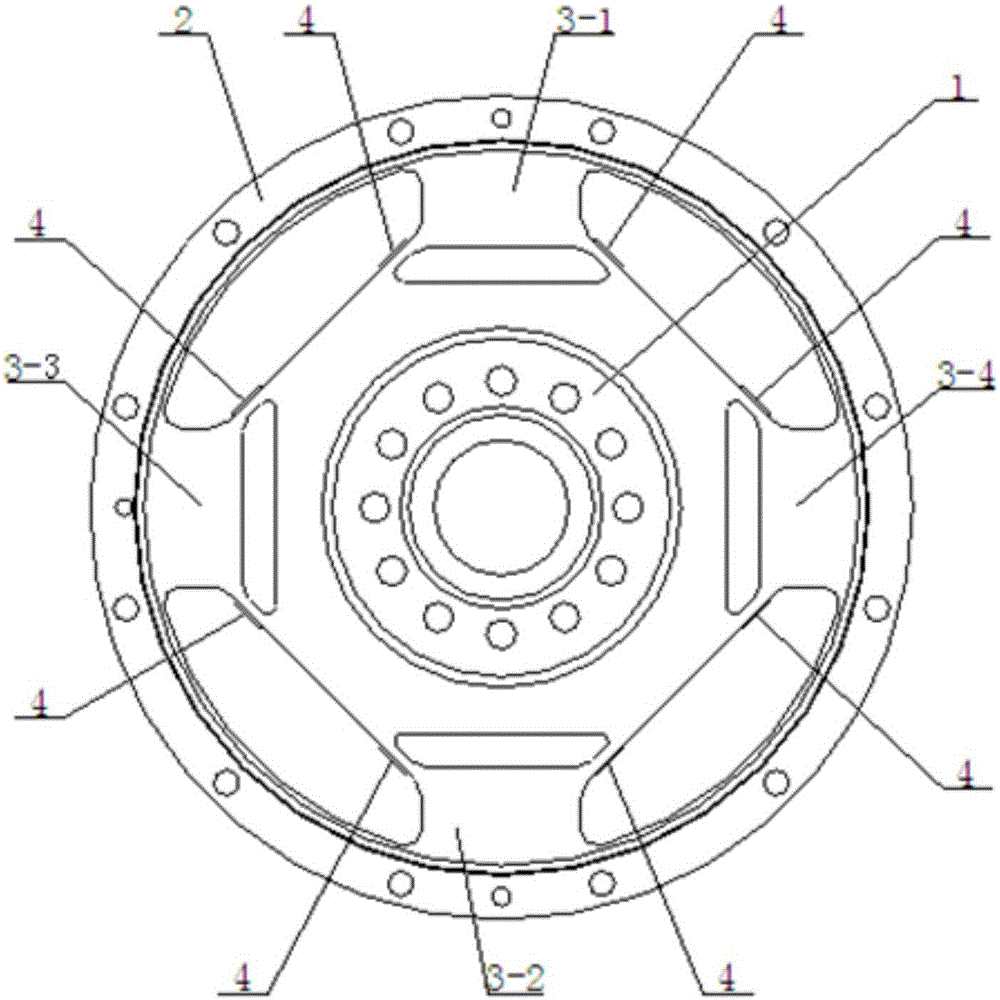

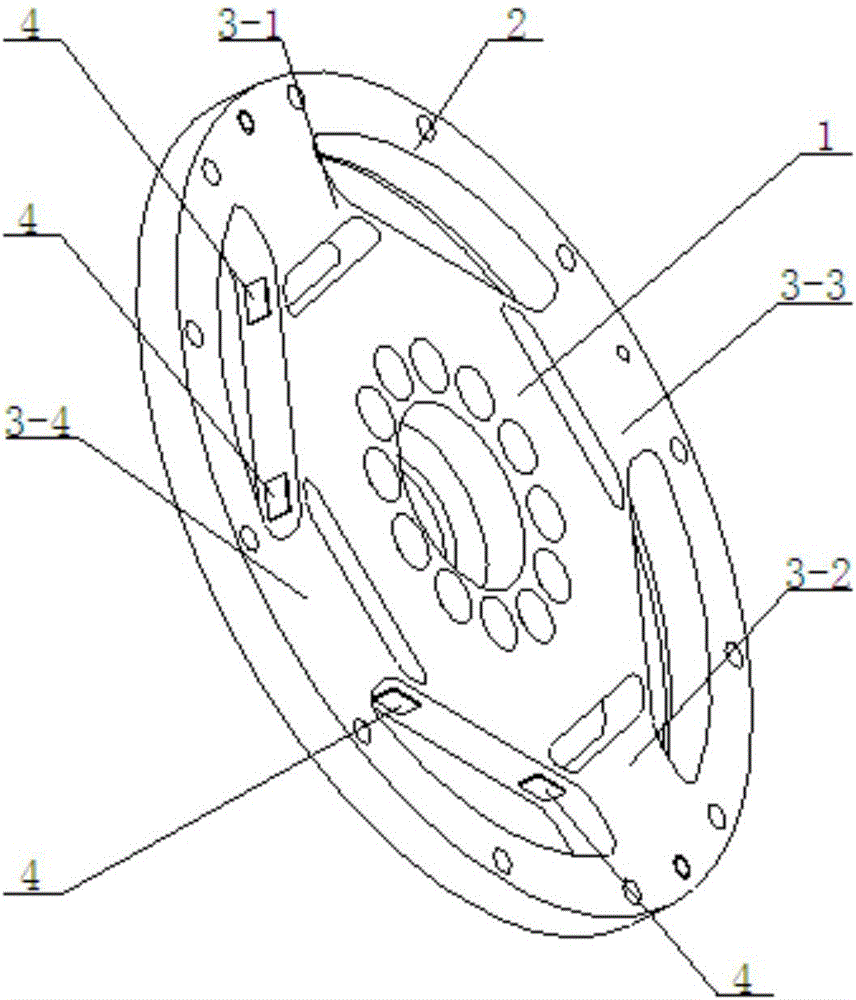

[0017] Embodiment one: the following combination figure 1 and figure 2 This embodiment will be described in detail.

[0018] The high-stiffness joint torque sensor described in this embodiment includes a torque input disk 1, a torque output disk 2, four strain beams and eight strain gauges 4;

[0019] The four strain beams are respectively a first strain beam 3-1, a second strain beam 3-2, a third strain beam 3-3 and a fourth strain beam 3-4, and the first strain beam 3-1, Both ends of the second strain beam 3-2, the third strain beam 3-3 and the fourth strain beam 3-4 are fixedly connected with the outer edge of the torque input disk 1 and the inner edge of the torque output disk 2 respectively, so that The first strain beam 3-1, the second strain beam 3-2, the third strain beam 3-3 and the fourth strain beam 3-4 are evenly distributed along the circumferential direction of the moment input disc 1;

[0020] On the strain beam, the two surfaces that are not parallel to the...

Embodiment 2

[0026] Embodiment 2: This embodiment further limits the high-stiffness joint torque sensor described in Embodiment 1.

[0027] In the high-stiffness joint torque sensor described in this embodiment, the strain gauge 4 is a metal foil resistance strain gauge.

[0028] The metal foil resistance strain gauge has small transverse effect, good heat dissipation performance, large current allowed to pass through, good flexibility, small creep and long fatigue life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com