Unfolding lofting method for large-size non-standard static equipment with tangential connecting pipes

A technology of non-standard static equipment and tangential connection, which is applied in the field of unfolding samples of large non-standard static equipment, can solve the problems of low processing precision, complicated methods, and affecting work, and achieve accurate and reliable data, simple unfolding, improved quality and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

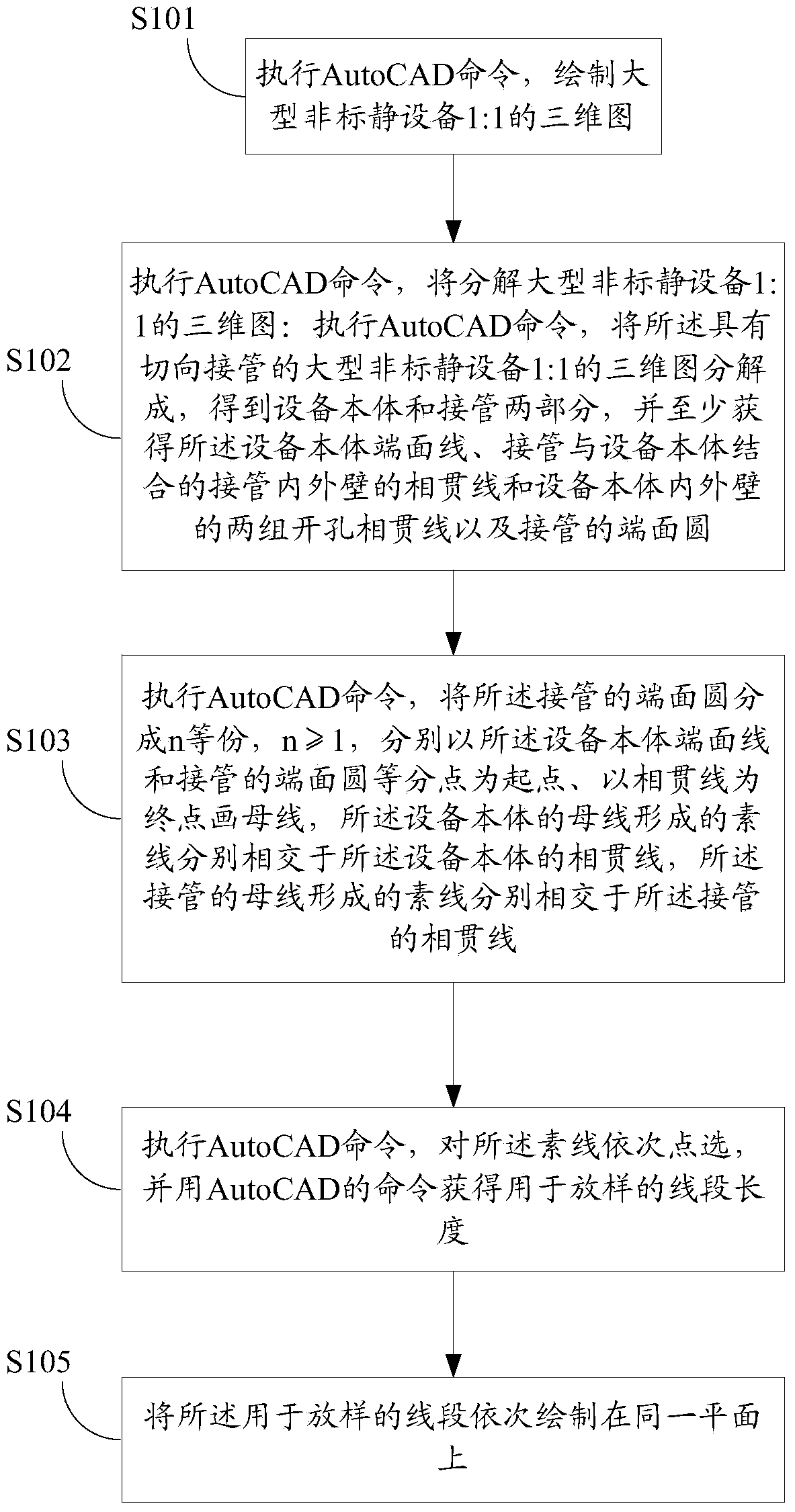

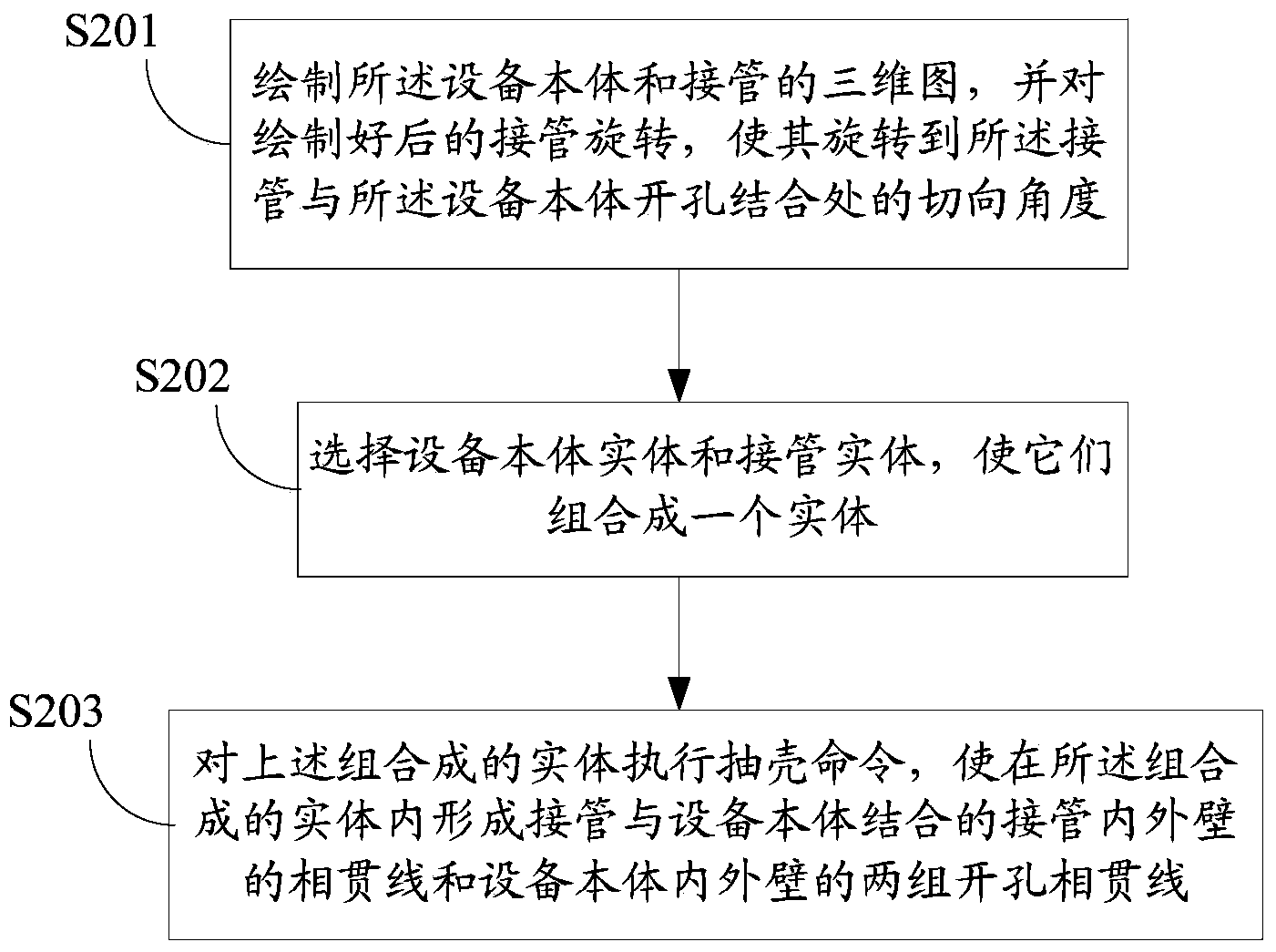

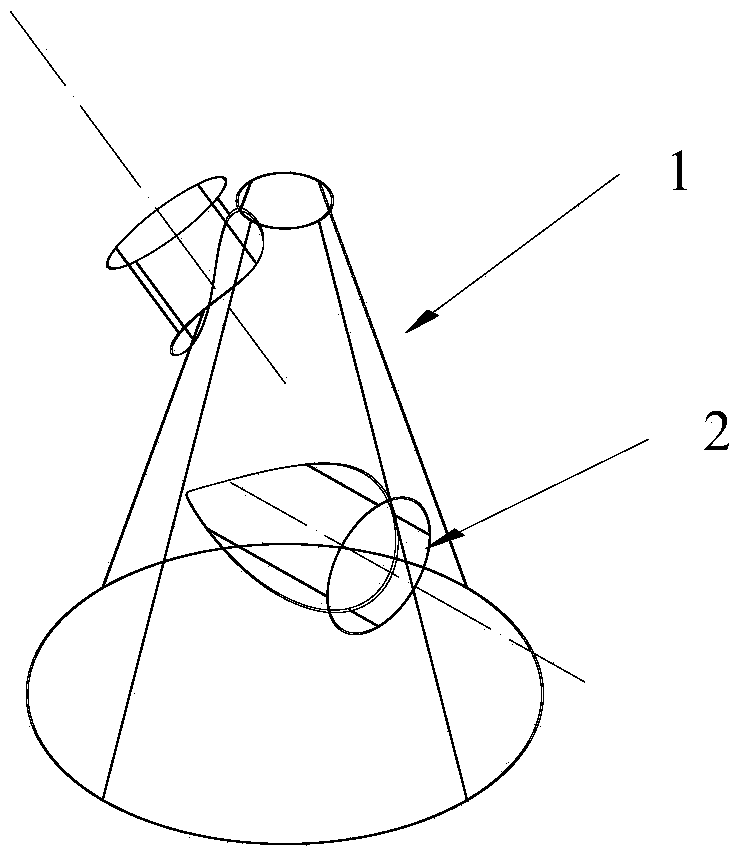

[0027] refer to figure 1 , the present invention is a sample opening method for large-scale non-standard static equipment with tangential nozzles. The large-scale non-standard static equipment with tangential nozzles includes a device body and a nozzle connected tangentially to the device body. The outer wall of the nozzle and the The device body is connected to the outer wall of the tangential opening, and the inner wall of the connecting pipe is connected to the inner wall of the tangential opening of the device body. The method includes:

[0028] S101: Execute AutoCAD commands to draw a 1:1 three-dimensional drawing of large non-standard static equipment;

[0029] S102: Execute the AutoCAD command to decompose the 1:1 three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com