Gob-side entry retaining reinforcing filling body structure and construction method thereof

A technology for filling bodies and entry retaining, which is applied in the direction of fillings, earthwork drilling, safety devices, etc. It can solve the problems of waste of wood and other raw materials, poor roofing effect, failure, etc., to achieve load-bearing characteristics, reduce erection, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

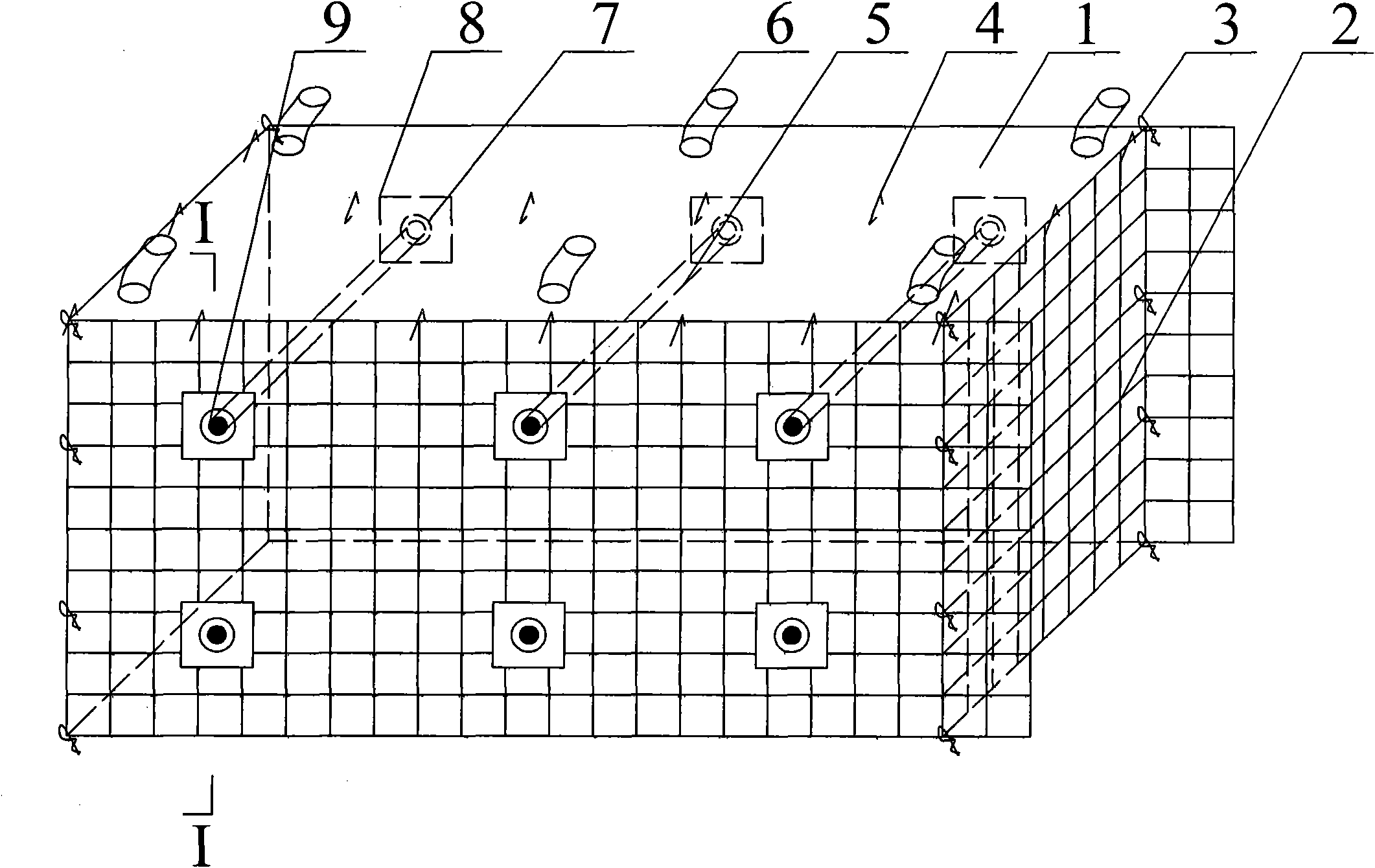

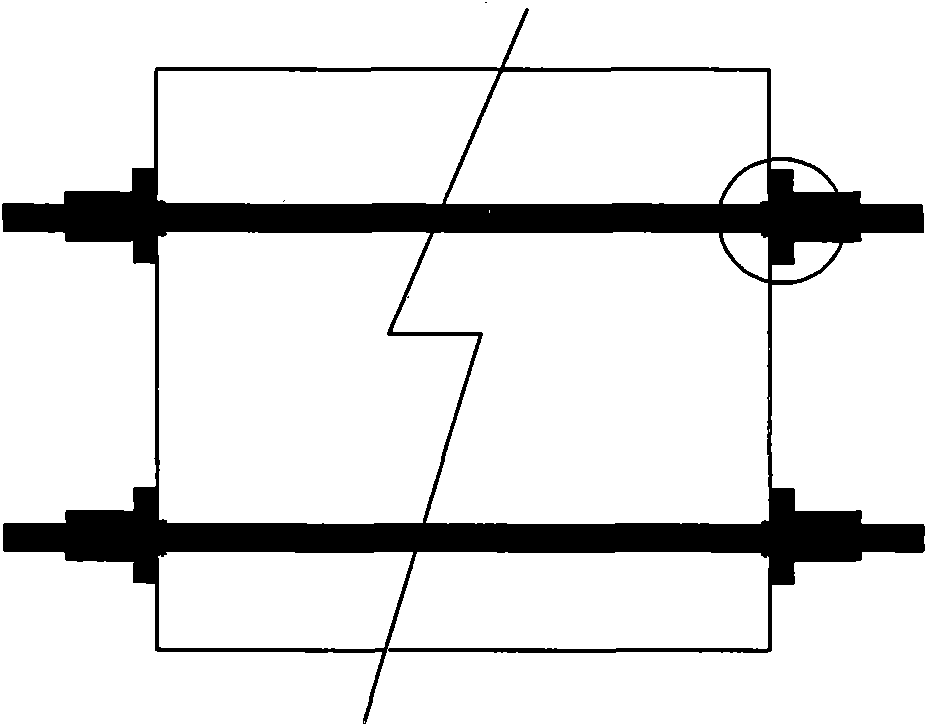

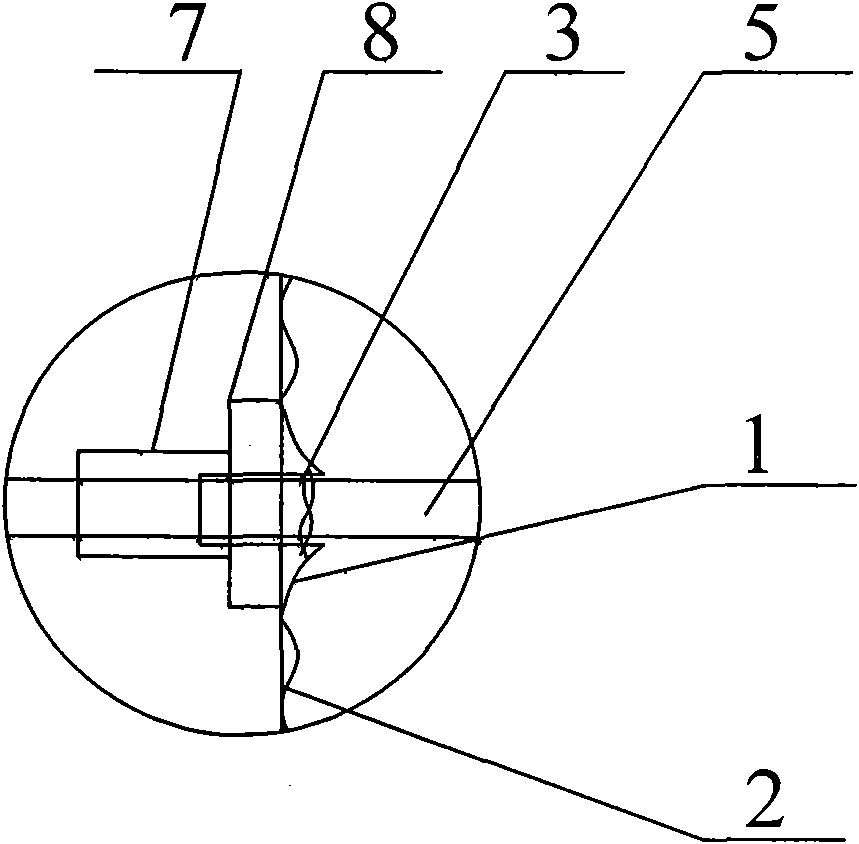

[0020] As shown in the accompanying drawings, the Gobside Entry Reinforced Filling Body Structure of the present invention includes a closed cuboid filling bag 1, and the top edge of the filling bag 1 is provided with several tops for filling and exhausting at intervals. The small bag 6 and the filling bag 1 are symmetrically arranged on both sides along the filling direction. There are several side small bags 9 that pass through the pull anchor rod 5. The pull anchor rod 5 passes through the side small bag 9, and its two ends are respectively equipped with trays. 8 and nut 7, the top and the periphery of the filling bag 1 are provided with some hooks 4 at intervals, and the surrounding of the filling bag 1 is provided with a mold-protecting steel mesh 2 fixed with iron wire 3.

[0021] The construction method of the gob-side entry retaining reinforcement f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com