Gob-side entry retaining reinforcing filling body structure construction method

A construction method and filling body technology, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of wasting raw materials such as wood, slow contact, and poor roofing effect, so as to achieve load-bearing characteristics, prevent layer separation, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

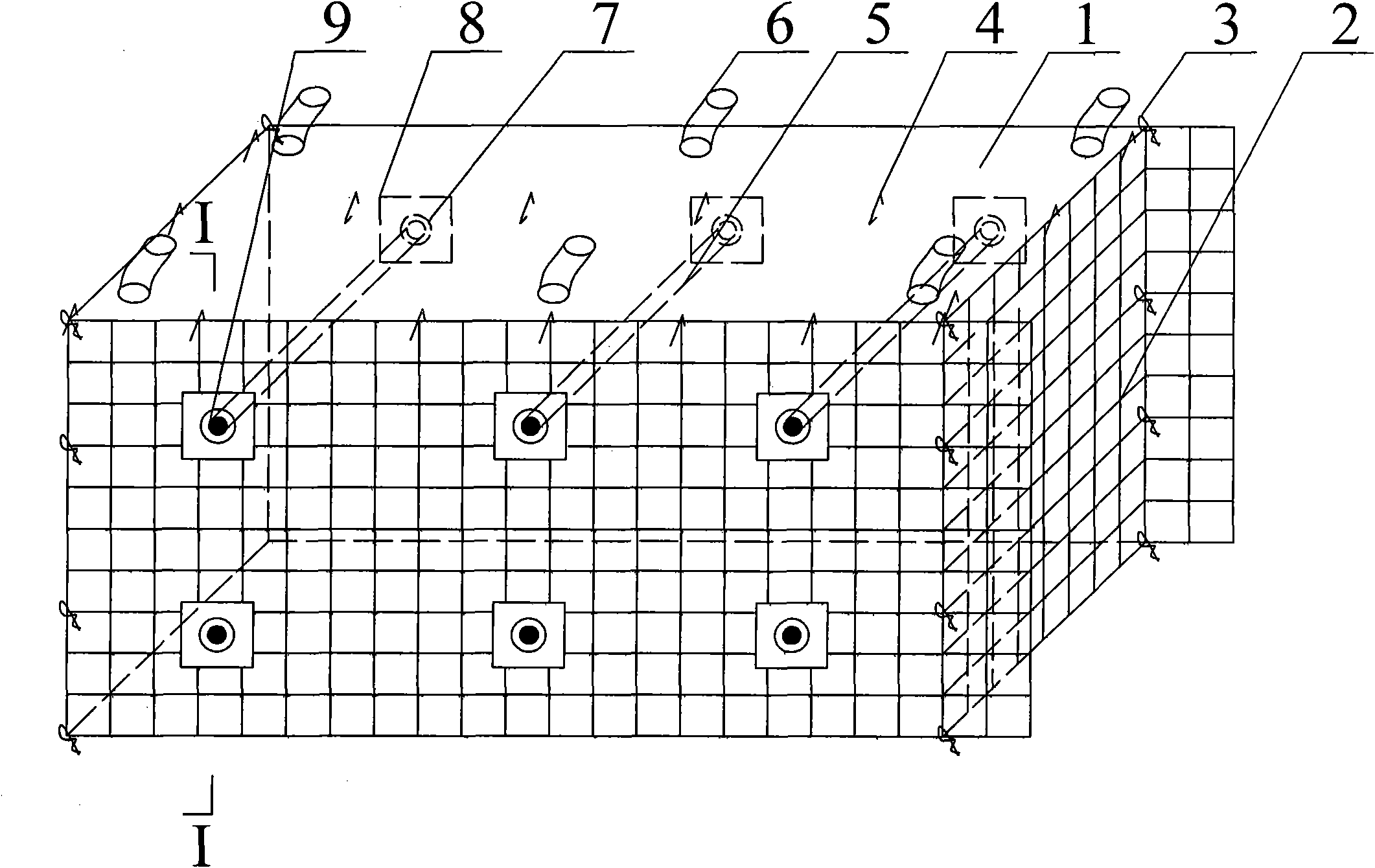

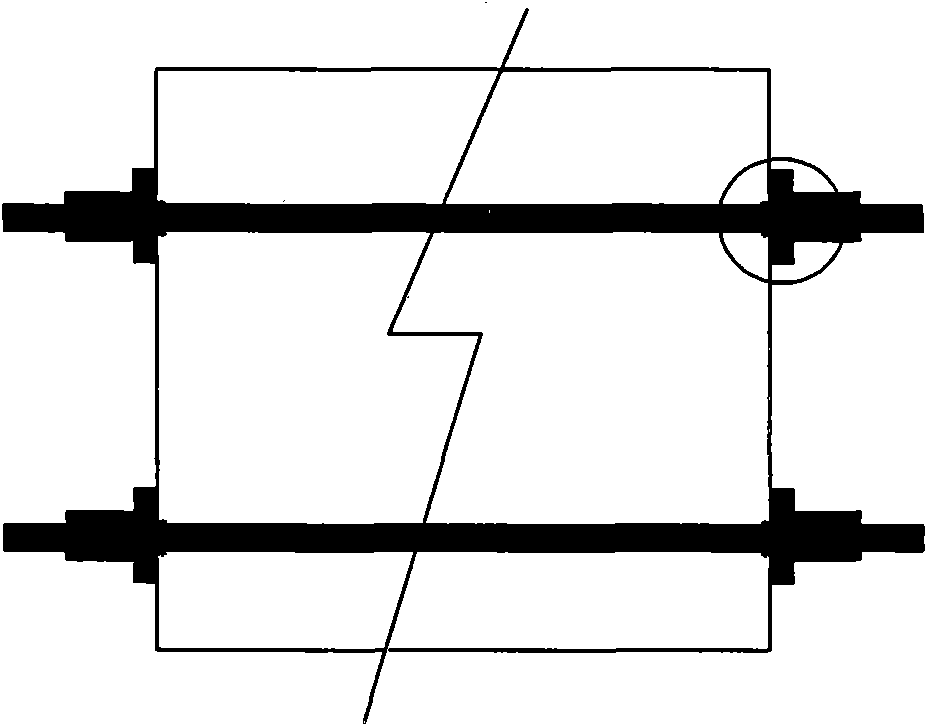

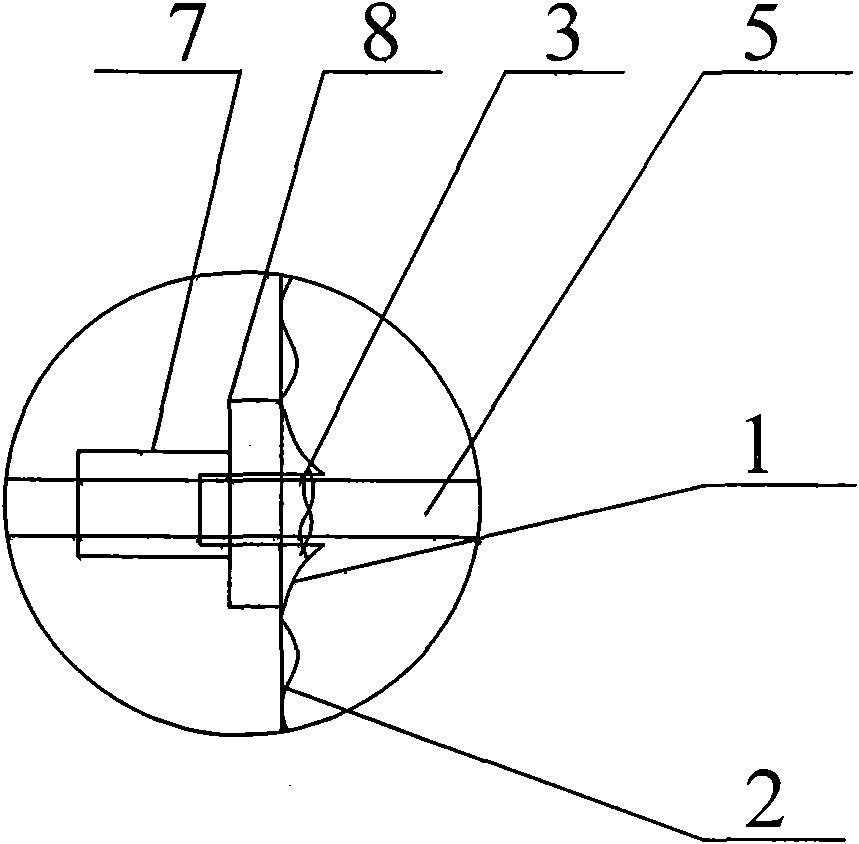

[0019] As shown in the drawings, the reinforced filling body structure along the goaf of the present invention includes a closed rectangular parallelepiped filling bag 1. The top edge of the filling bag 1 is provided with several tops for filling and exhausting. The small bag 6, the filling bag 1 is provided with several side small bags 9 symmetrically spaced along the filling direction on both sides of the anchor rod 5, the anchor rod 5 passes through the side small bag 9, and the two ends are respectively equipped with trays 8 and nut 7, a number of hooks 4 are arranged at intervals between the top and the periphery of the filling bag 1, and a mold-protecting steel mesh 2 fixed with iron wire 3 is arranged around the filling bag 1.

[0020] The construction method of the present invention for reinforcing the filling body structure along the goaf reserved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com