Stripe gob filling repeated-mining method

A goaf and strip technology, which can be used in filling, ground mining, mining equipment, etc., can solve problems such as waste of coal resources, improve the recovery rate of coal resources, and eliminate hidden dangers of geological disasters in mining areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] combine Figure 1 to Figure 5 , a strip goaf filling and re-mining method, comprising the following steps:

[0026] Step 1: Open the airtight wall of the main roadway in the strip goaf to ventilate and discharge possible residual harmful gases, such as residual gas.

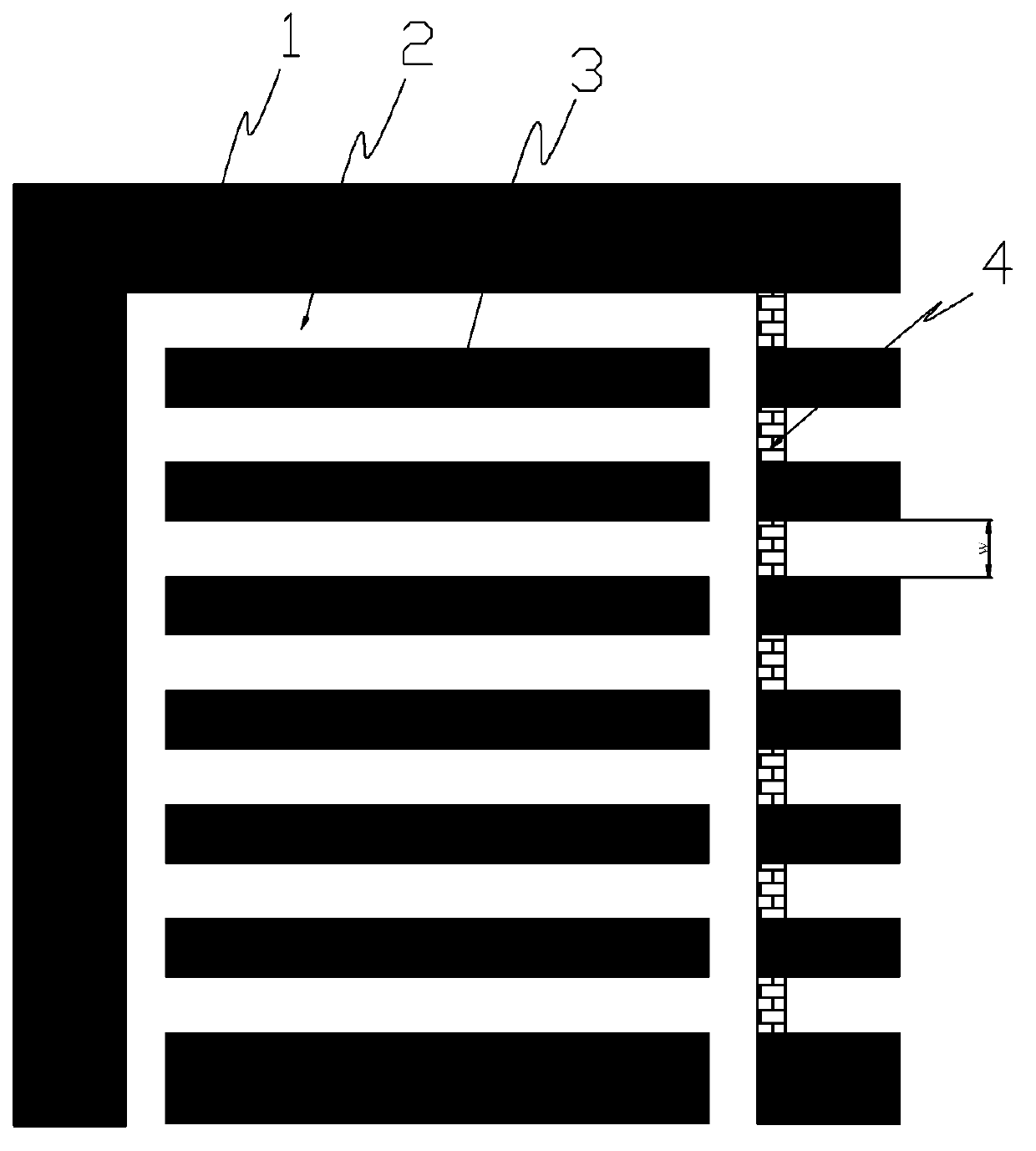

[0027] Step 2. After step 1 is completed, the roadway in the strip goaf is cleaned up, and the partially broken roof is reinforced to remove accumulated water. For the above two steps, please refer to figure 1 .

[0028] Step 3: after step 2 is completed, paste filling material is used to fill the empty strip in the goaf of the strip to form filling strip 1. This procedure includes the steps to determine the unidirectional strength of the paste filling material:

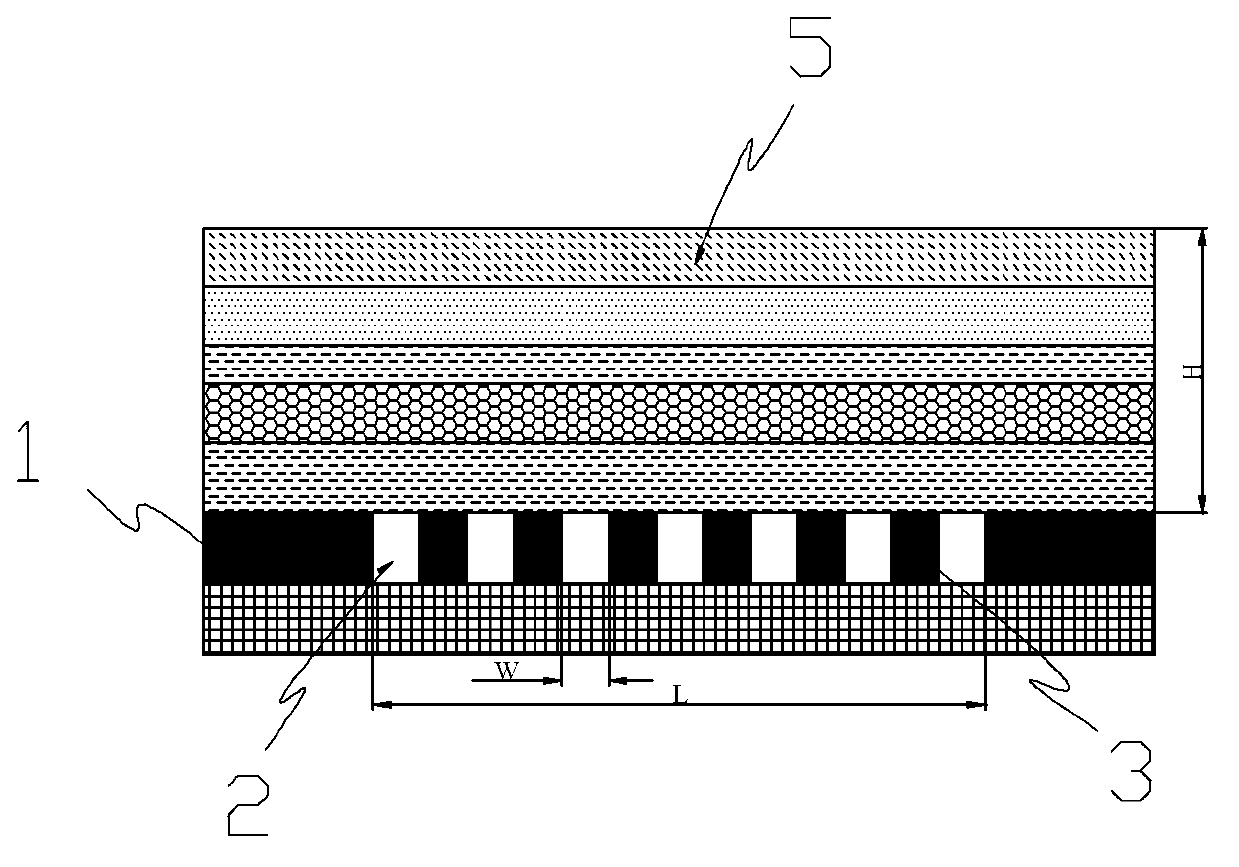

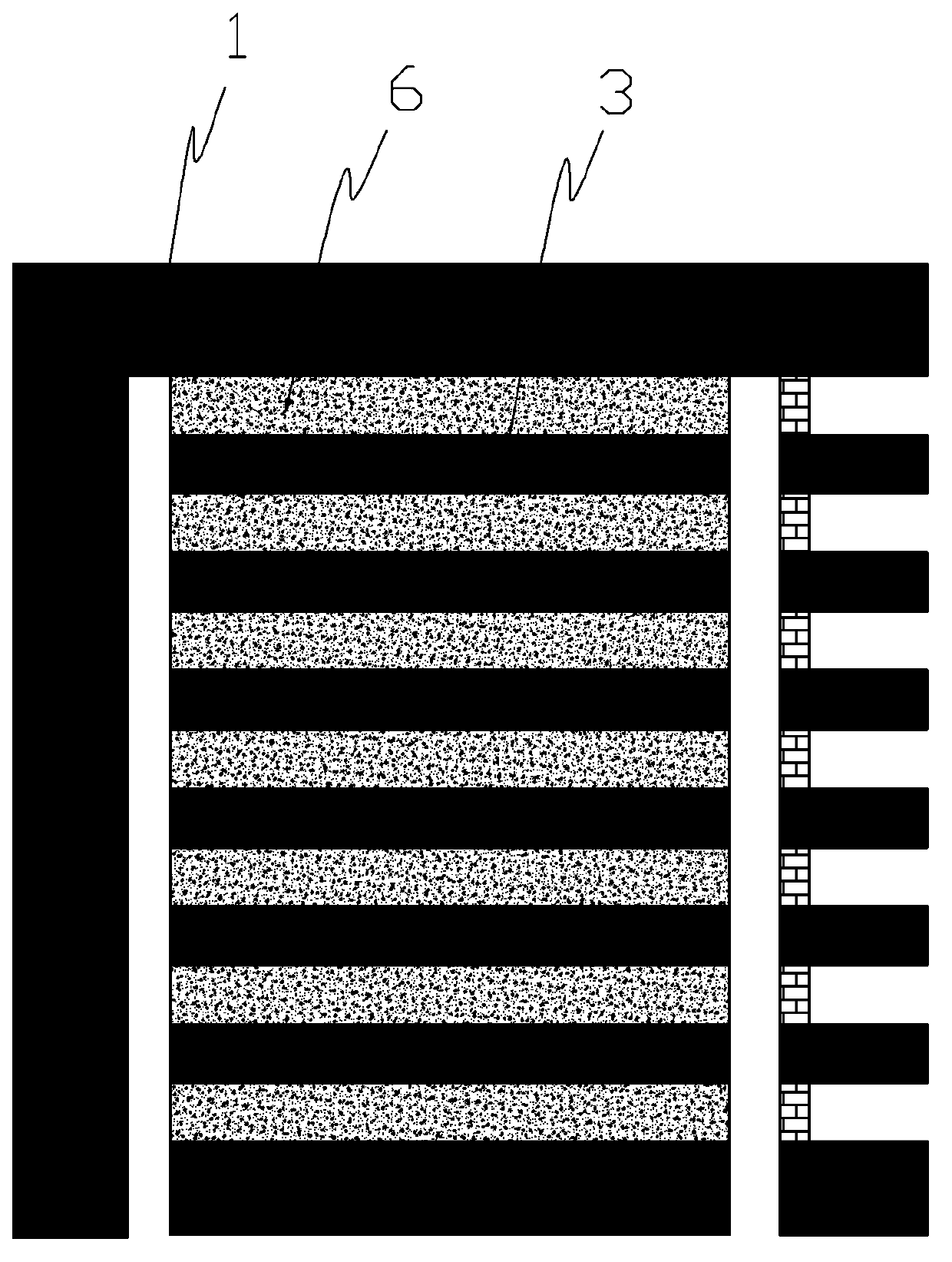

[0029] key reference figure 2 and image 3 , assuming that there are N1 empty strips and N2 leftover coal pillars in a goaf. Paste filling materials are used to fill the N1 empty strips, and the sum of the support capacity of the N1 filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com