Sandy soil water-immersion testing method for loess collapsible deformation

A test method and technology of collapsible loess, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of disturbance, limited test points, and high cost of immersion test pits, etc., and meet the low requirements of the site , The principle is simple and clear, and the test results are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

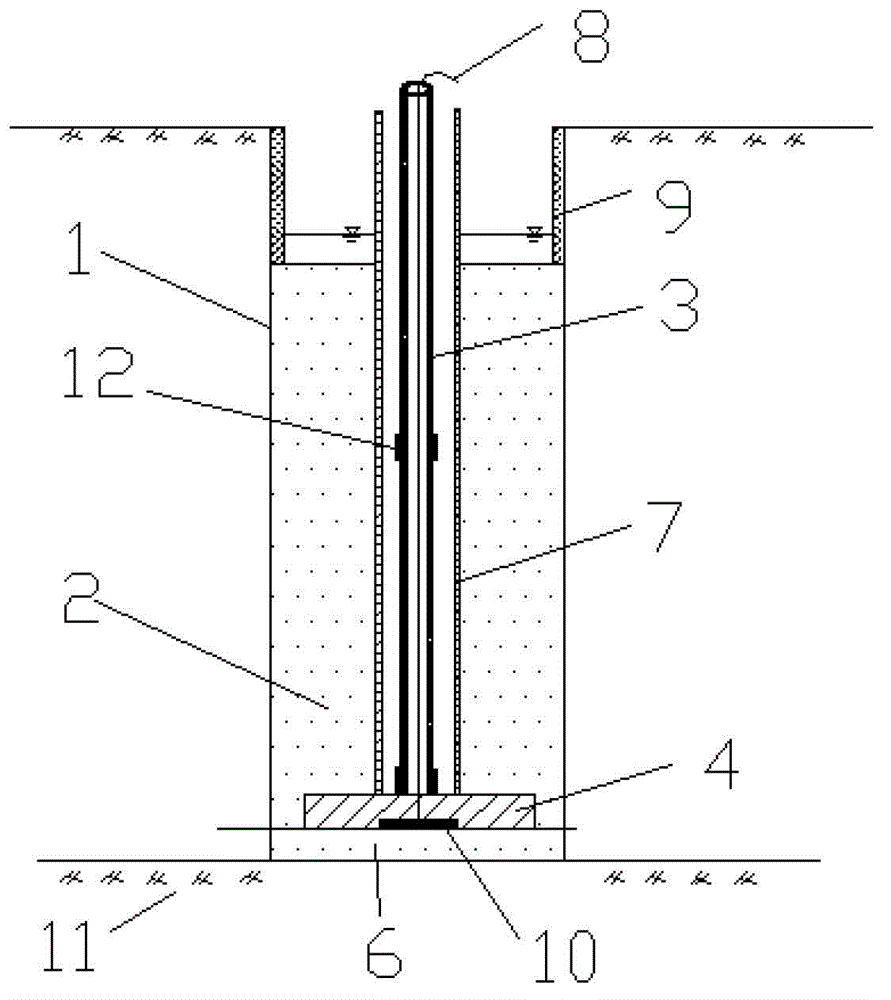

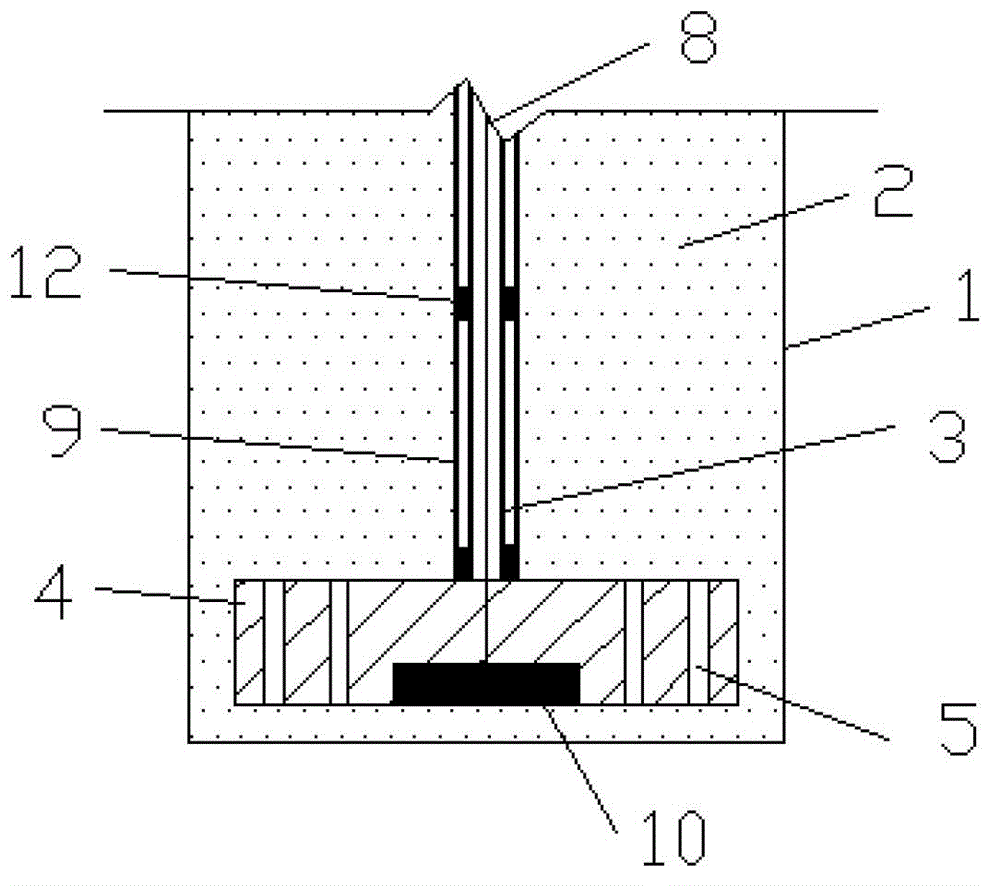

[0021] Such as figure 1 Shown, the sand soaking test method of loess collapsibility deformation of the present invention, carries out according to the following steps:

[0022] Step 1. Excavate an exploratory well 1 with a circular cross-section vertically downward on the surface of the stratum. It is required that the exploratory well 1 is vertical and regular circular during excavation, so as to facilitate the lowering of the bearing plate 4 . The collapsible loess 11 below the exploratory well 1 is the soil to be tested.

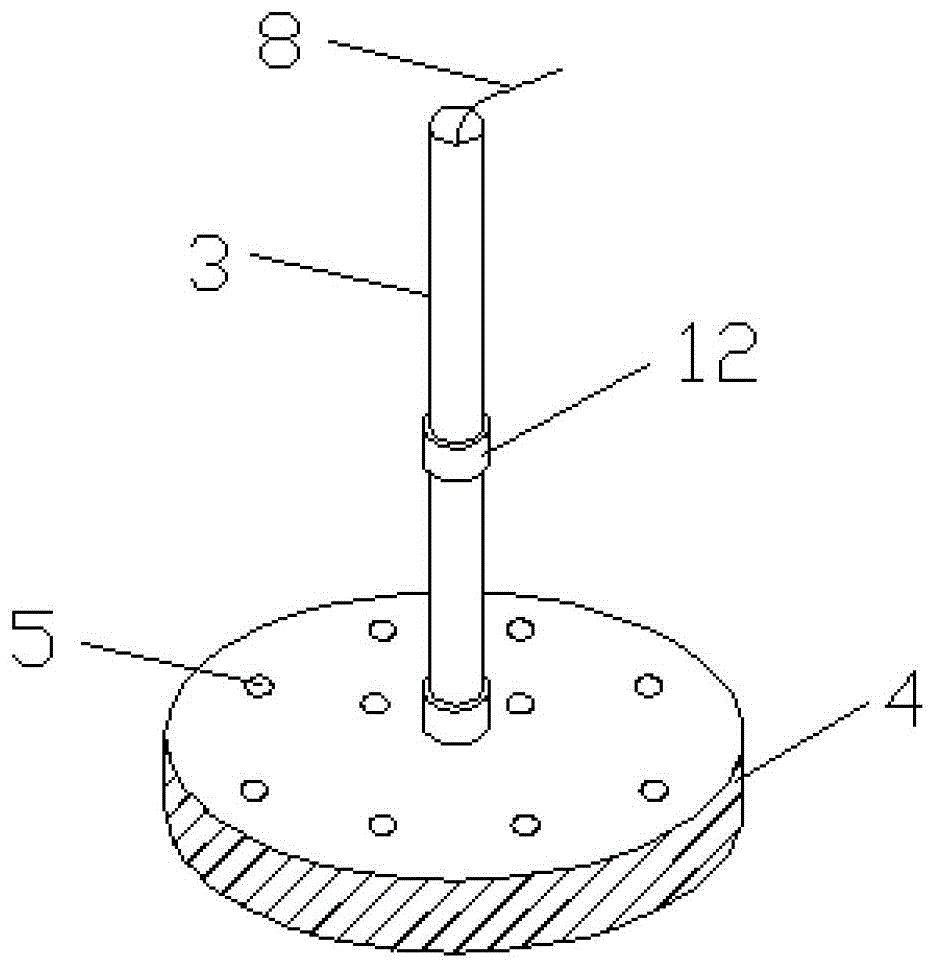

[0023] Such as Figure 2 to Figure 4 As shown, the settling rod 3 and the bearing plate 4 constitute the detection device used in the method of the present invention. Select the bearing plate 4 with a diameter smaller than that of the exploration well 1. The bearing plate 4 is a circular rigid plate and has a plurality of vertical permeable holes 5 evenly opened on the plate body. The vertical permeable holes 5 can ensure that the water in the explorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com