Primary support construction for shallow-buried extra-large section tunnel crossing highway underneath in uneven strata

A technology for initial support and expressway, applied in tunnels, tunnel linings, underground chambers, etc., to reduce the impact, reduce the spacing between pipe sheds, and avoid spalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

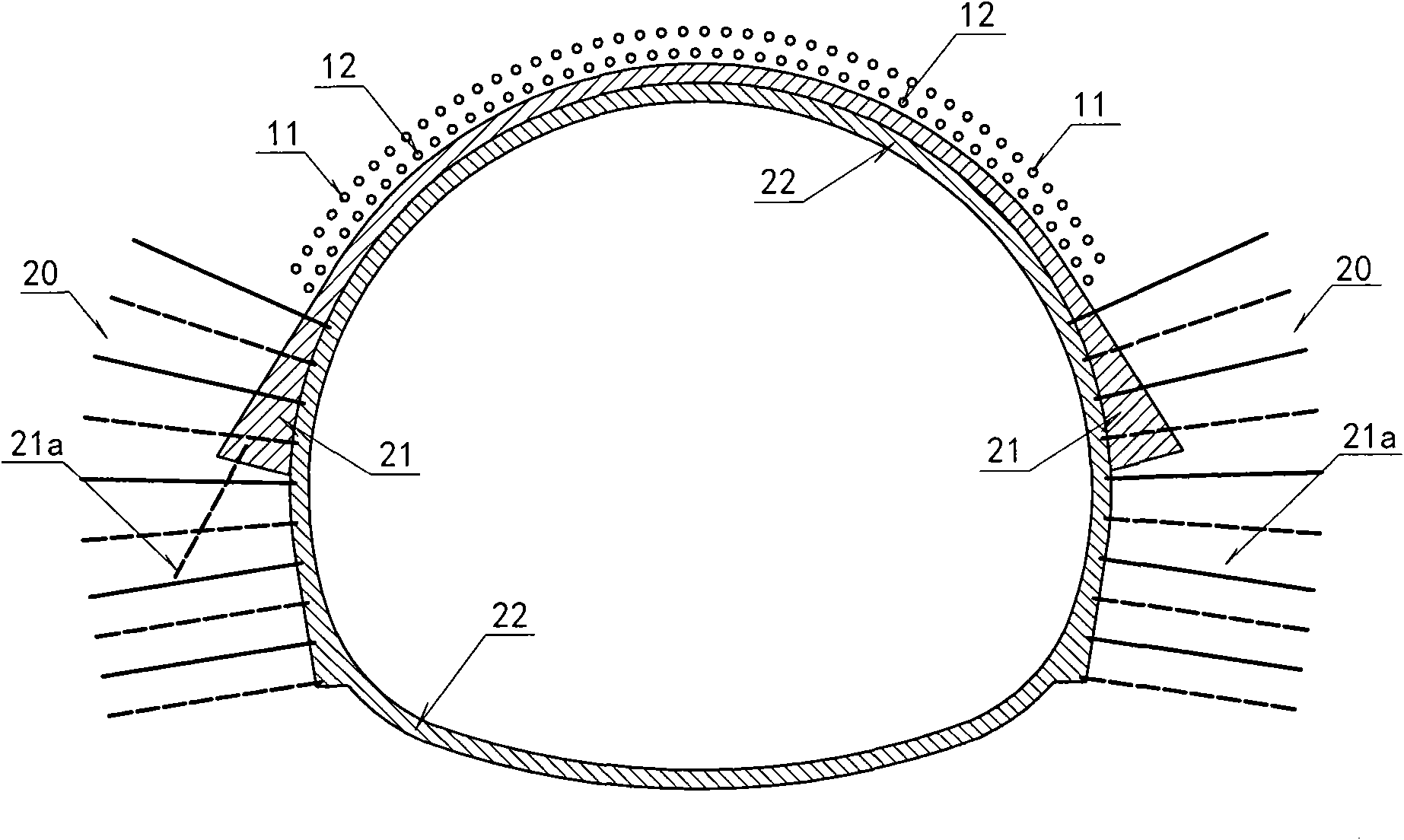

[0011] refer to figure 1 According to the present invention, the primary support structure of super-large-section tunnels buried under shallow highways and passing through heterogeneous strata includes advanced support structures and primary support structures. The advanced support structure is composed of outer large pipe shed 11 and inner large pipe shed 12 arranged radially at intervals. The use of double-layer large pipe shed advance support can increase the rigidity of the pipe shed, reduce the distance between the pipe sheds, and avoid The soil between the pipes peels off, effectively reducing the impact of excavation deformation on the surface. The side wall system anchor rod 20 is arranged in the soil outside the side wall section of the outer lining, and the primary support structure is composed of an arch outer support layer 21 formed by shot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com