Three-step non-reserved-core-soil construction method for large-cross-section tunnel at collapsible loess area

A technology of collapsible loess and reserved core soil, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of frequent surrounding rock disturbances, slow construction progress, and long construction time, and shorten the excavation construction time, increase construction progress, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

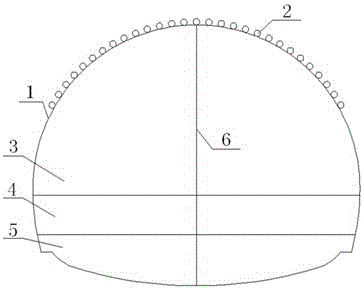

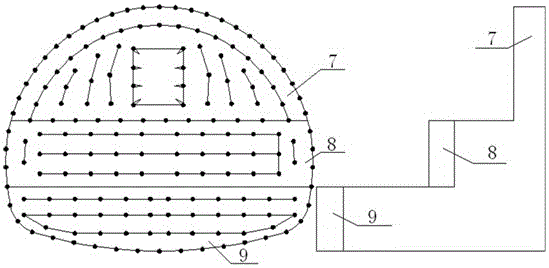

[0030] Example: The tunnel is one-way, two-lane, and the total length of the tunnel is 2550m. The standard section span of the tunnel is 12.46m, the height is 9.84m, and the excavation volume is 109.9m 3 , the span of the widening section is 14.68m, the height is 11.3m, and the excavation area is 129.7m 2 , for large-section tunnels. The surrounding rock of the tunnel is mainly Quaternary aeolian new loess with a water content of 12.76-14.56, which is a typical collapsible loess rock formation.

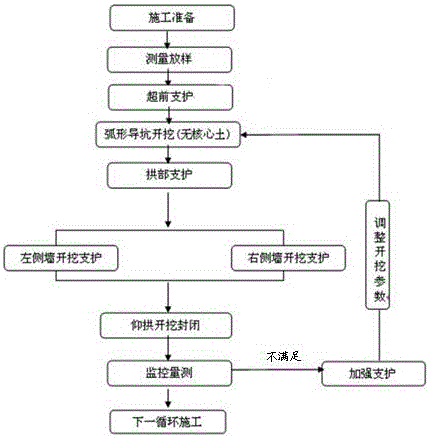

[0031] First, the construction process: such as figure 1 shown.

[0032] Step S01: Construction preparation: establish a comprehensive forecasting system, use geological method, engineering geological analogy method, and geological sketch method for macroscopic analysis and forecasting, use geological radar and advanced sounding for revealing verification forecasting, and reveal formation lithology, The degree of development of the structural plane of the rock mass, the size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com