A liftable support system for a subway foundation pit and its lifting construction method

A technology of support system and foundation pit, which is applied in the fields of foundation structure engineering, excavation, construction, etc., can solve the problems of difficult construction, low efficiency, and the time and space of horizontal support of foundation pit and earthwork excavation cannot meet each other, so as to avoid foundation pit. The effect of pit safety hazards, ensuring reliability, and shortening the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

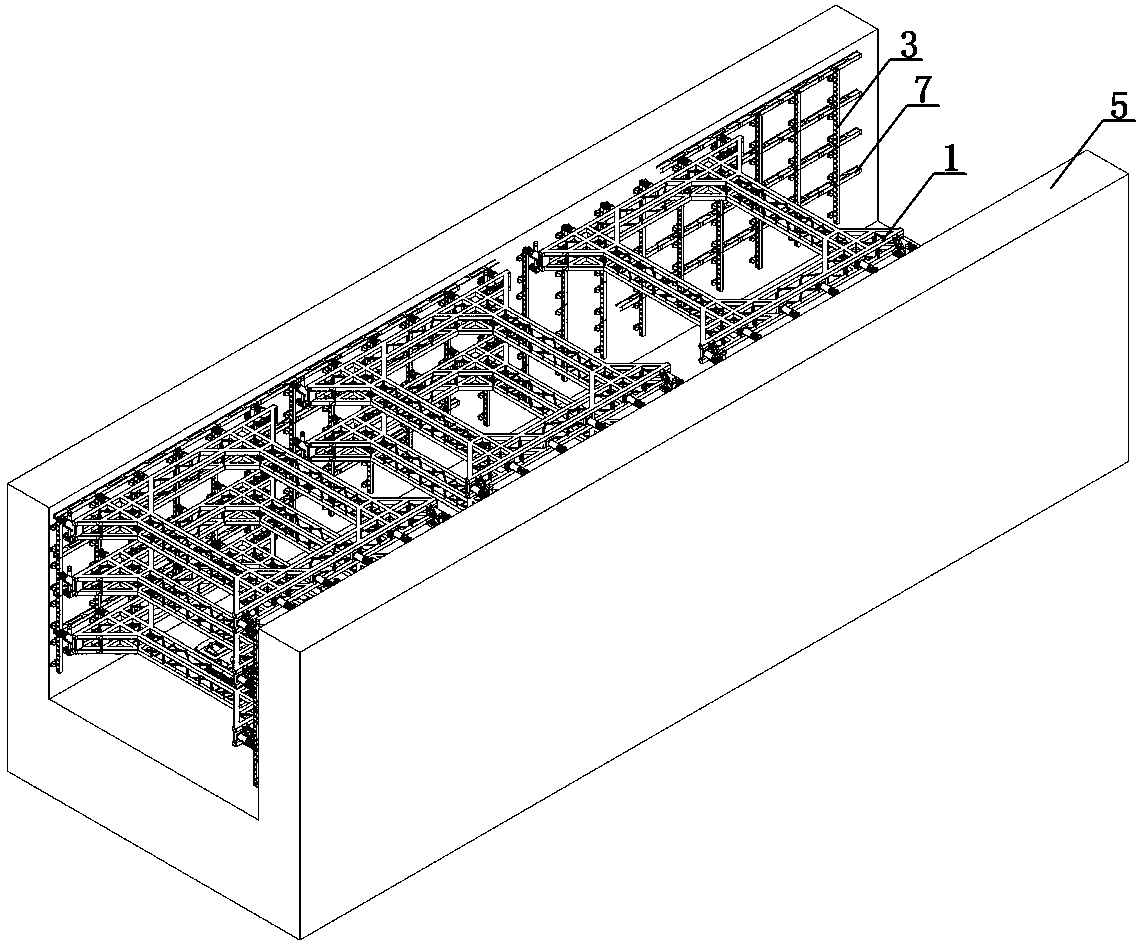

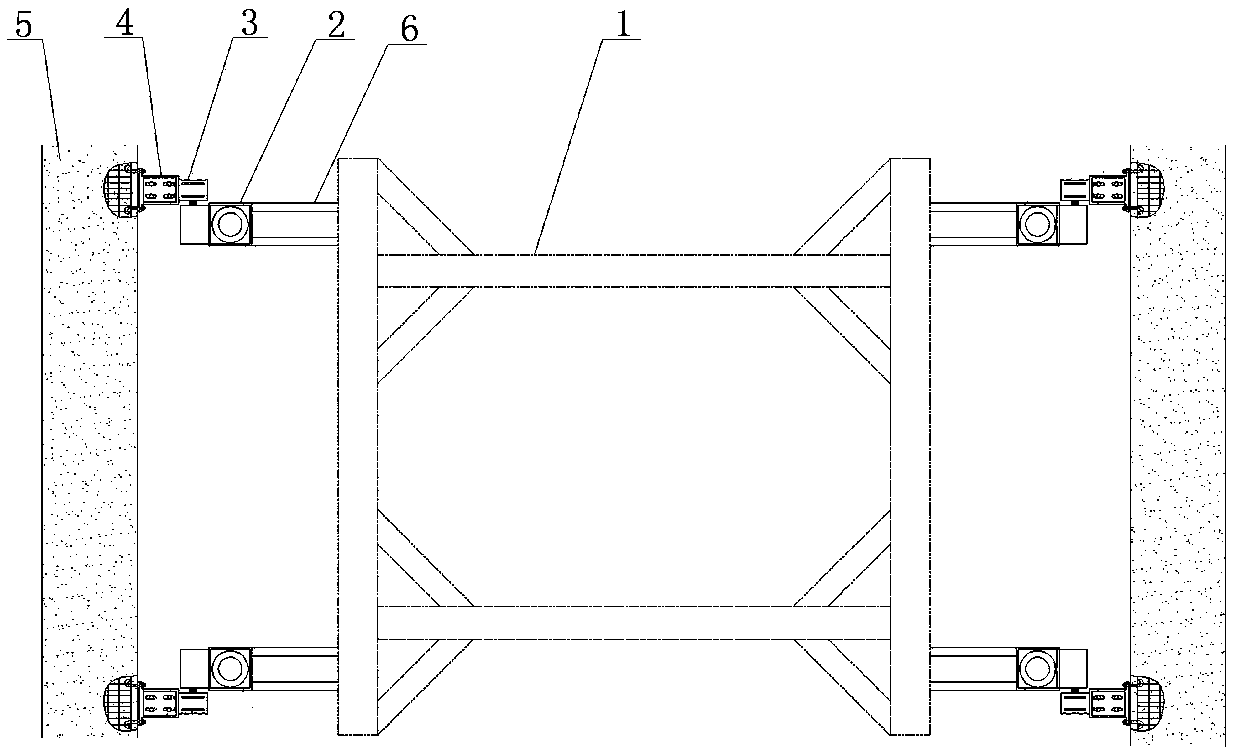

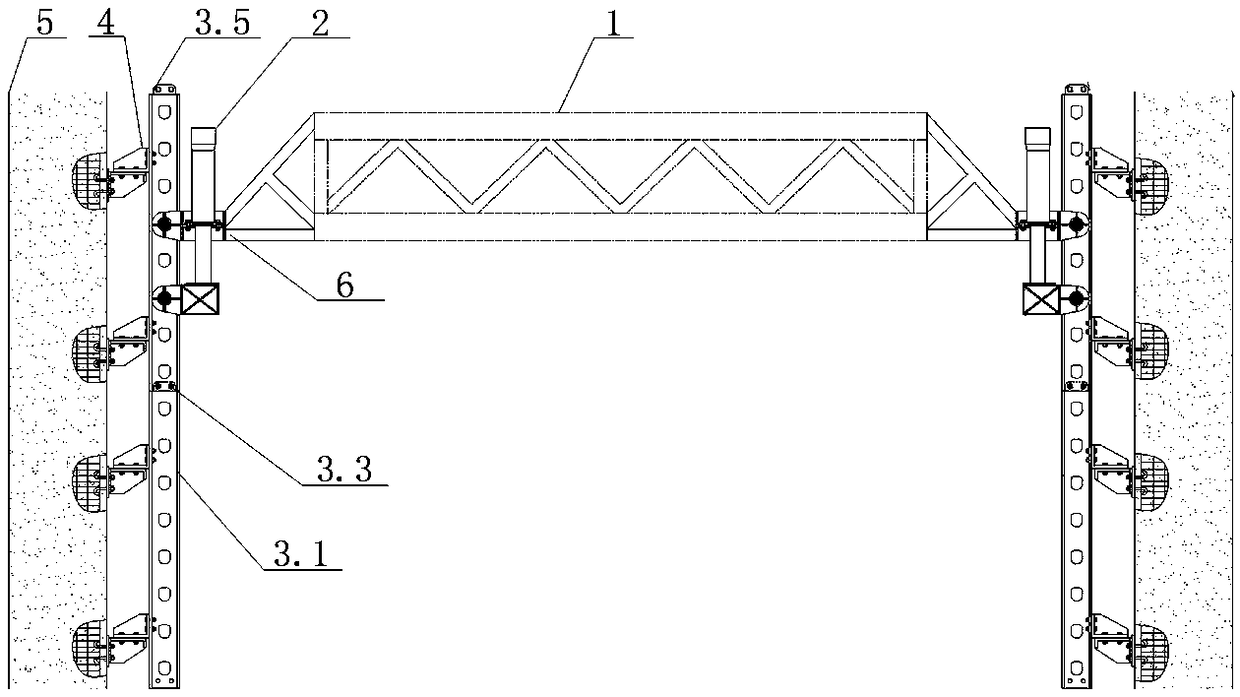

[0060] Examples see figure 1 As shown, the liftable support system of this subway foundation pit includes horizontal support units horizontally supported between the foundation pit enclosure structures 5, and the horizontal support units are evenly distributed in parallel intervals along the length and height direction of the foundation pit, so The horizontal support unit includes a horizontal support platform 1 and a lifting power unit 2 connected to the two ends of the horizontal support platform 1. The lifting power unit 2 is connected with the foundation pit enclosure structure 5 through a guide rail 3, wherein the guide rail 3 is along the foundation pit enclosure. The length direction of the structure 5 is arranged in parallel and at intervals; the guide rail 3 is vertically spliced by the guide rail unit 3.1 along the height direction of the foundation pit enclosure structure 5; A group of purlins 7 are arranged at parallel intervals in the height direction of the pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com