Construction method for large-span section loess tunnel under-crossing highway

A technology for loess tunnels and highways, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as complex construction, safety accident economy, loss, etc., to solve construction technical problems, speed up construction progress, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

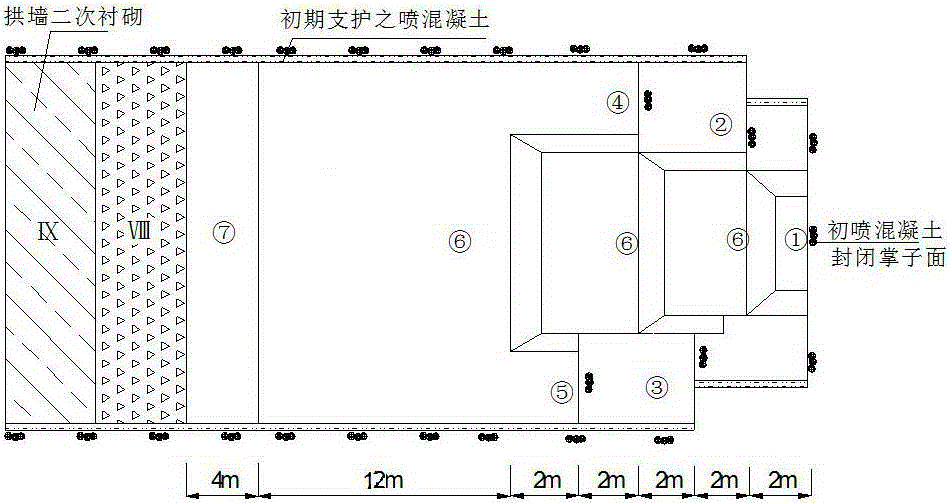

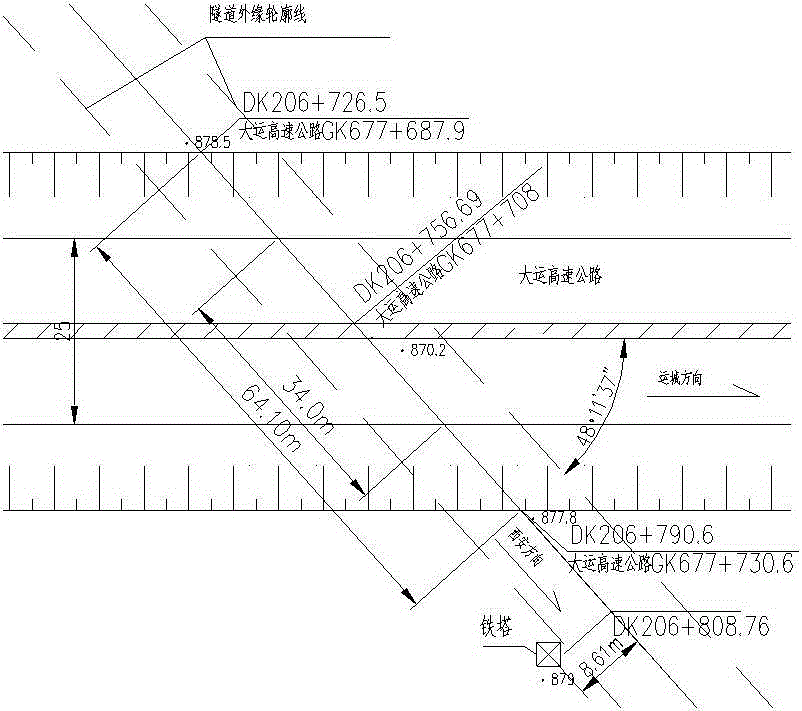

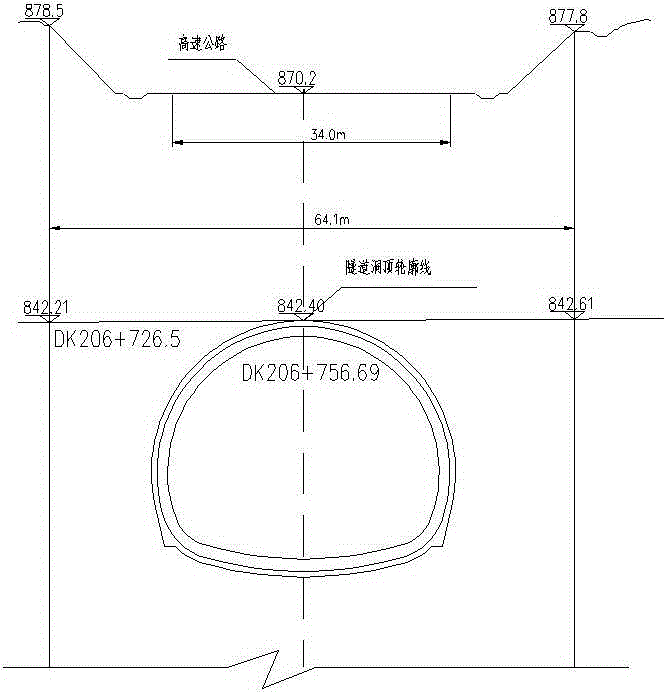

[0031] Embodiment 1: When implementing the technical scheme of the present invention, a loess railway tunnel with a large-span cross-section of a passenger dedicated line is selected to pass under the expressway project (see the attached section for the plane and cross-section of the section below). Figure 1~2 ), and successfully applied this construction method to cross the road, the main construction process is shown in the attached Figure 3~8 shown.

[0032] The specific steps of the construction method of the large-span section loess tunnel passing under the expressway are as follows:

[0033] Step 1. Excavate the pipe shed studio at the front of the underpass section of the tunnel (DK206+820~DK206+830 section); before the excavation construction of the underpass expressway section, reserve a long pipe shed workroom during the preliminary construction. The working room is 1 meter wider than the normal tunnel to ensure the construction work space of the φ159mm large tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com