Construction method for tunnel trunk penetrating through loess interface water-rich strata

A construction method and technology of water-rich strata, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low construction efficiency, sudden surge of sand layers on the tunnel face, and increased construction costs, so as to improve construction efficiency and prevent The effect of sand bursting and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is applied to the construction process of the large-section tunnel body passing through the water-rich stratum at the loess interface.

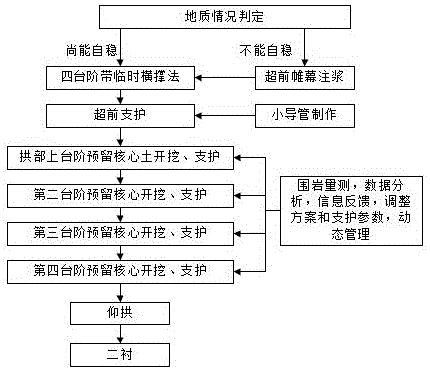

[0046] Such as figure 1 As shown, the construction method of the tunnel body passing through the water-rich stratum at the loess interface adopts the following steps:

[0047] Step a: Investigate and analyze the geological conditions of the tunnel body passing through, systematically analyze the geological survey data, mark the positions of valleys and caves under the large-section loess tunnel body on the design drawings, and conduct field surface investigation and analysis along the corresponding surface of the tunnel , and mark special parts such as shallow burials, grooves and pits without exploration data on the drawings. Then use geological drilling rigs to drill holes on the dense surface of special parts without exploration data. The drilling depth is at least 10m below the bottom of the tunnel, and the transit...

Embodiment 2

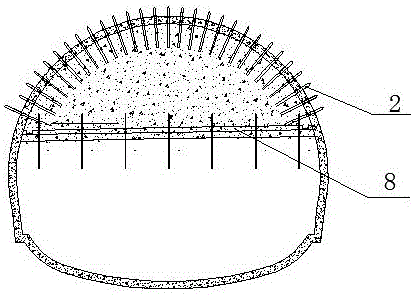

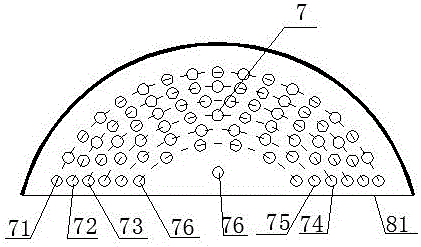

[0066] This embodiment is applied to the occasion where the tunnel body passes through the loess interface stratum, and at the same time, it is necessary to inject grouting ahead of the curtain at the arch of the tunnel body.

[0067] The overall steps of this embodiment are the same as those of Embodiment 1, the difference is that in step c of embodiment 1, when it is necessary to use advanced deep hole curtain grouting according to the stability of the tunnel face, it is necessary to perform grouting in step c Add multiple steps between step d.

[0068]In step c of Example 1, a targeted plan is formulated according to the stability of the tunnel face to determine whether to use advanced deep hole curtain grouting, and to detect the hydrology of the loess stratum based on the tunnel geological survey data combined with the face and advanced drilling According to the geological data, a targeted advanced grouting and excavation plan is formulated. The tunnel body passes through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com