Open pit coal mine mining process

An open-pit coal mine and process technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as affecting work efficiency, blasting and brushing, reducing coal mining output, etc., to ensure the continuity of cooperation and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

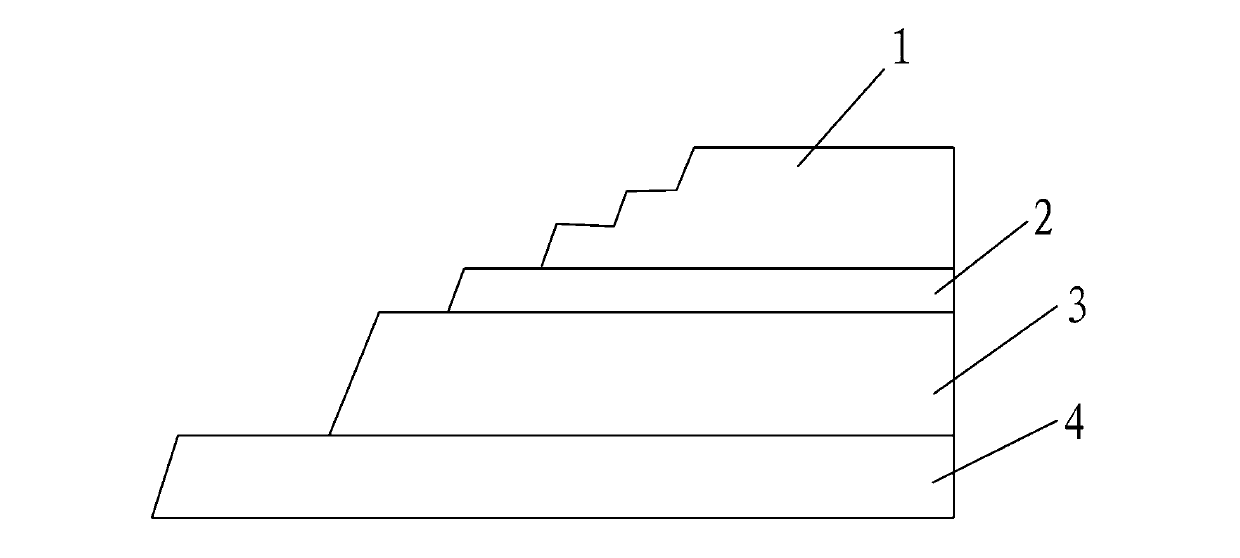

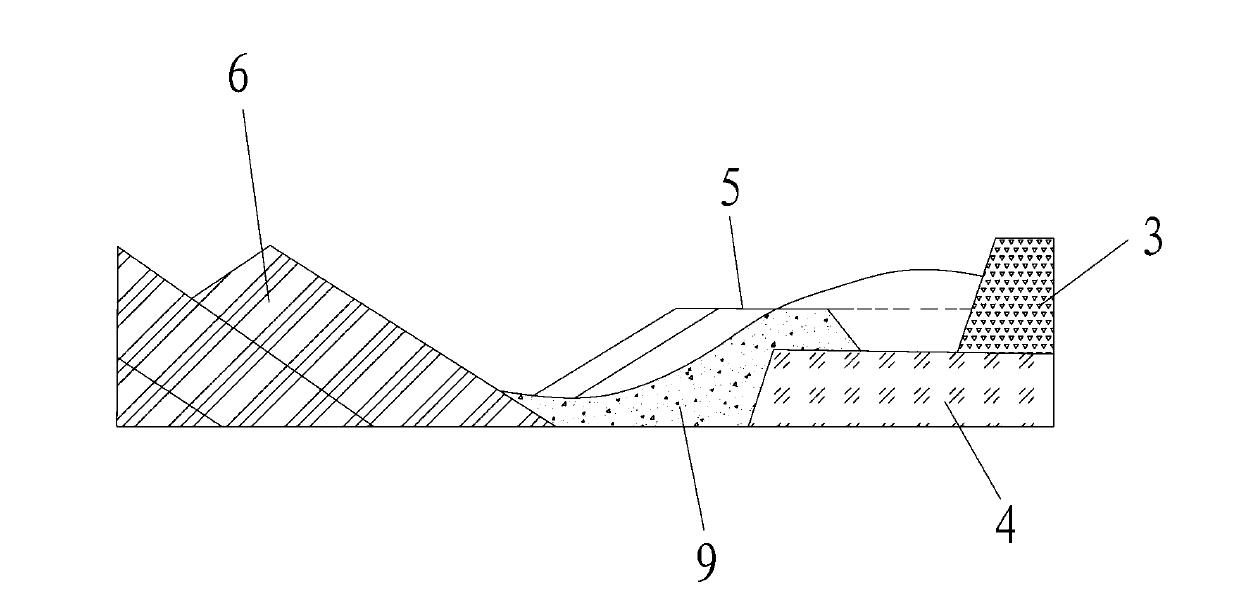

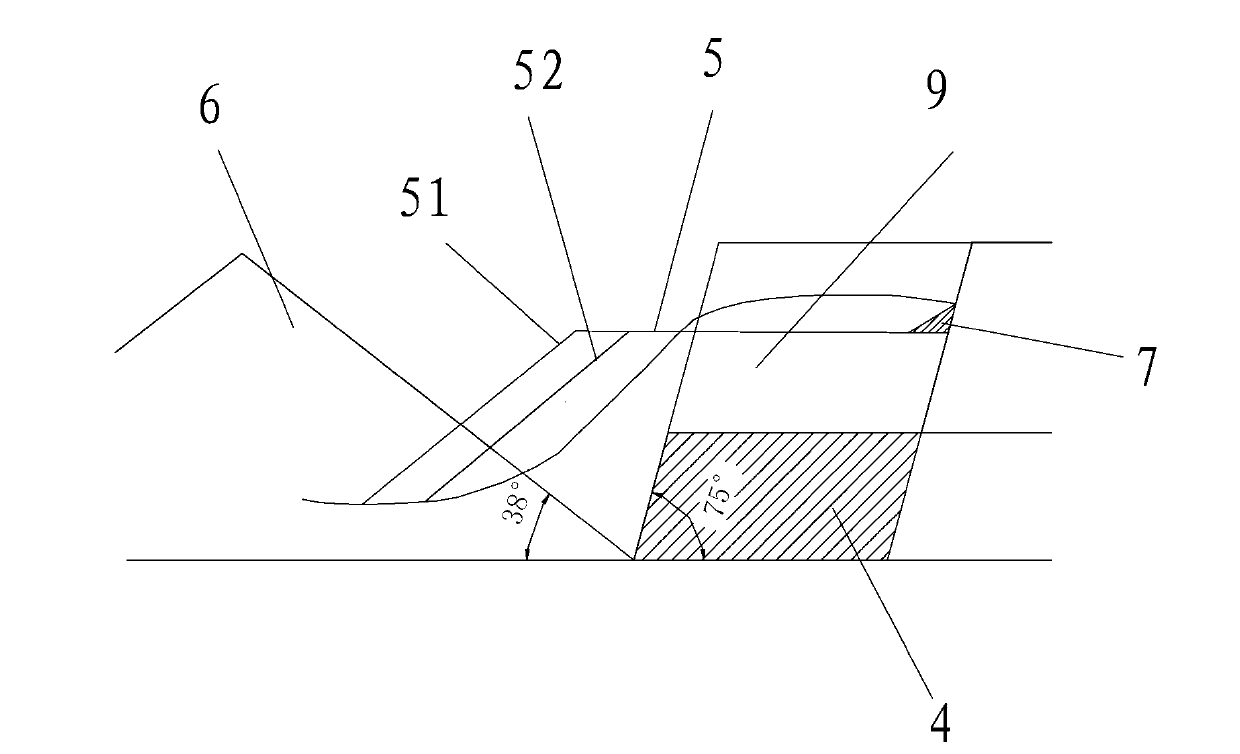

[0021] This embodiment provides a kind of open-pit coal mine mining technology, and this open-pit coal mine is as figure 1 Shown includes an upper loess layer 1, a middle rock layer 2, a lower rock layer 3, and a coal seam 4 below the lower rock layer 3, combined with Figure 2-3 , the operation steps are as follows: excavate the upper loess layer 1 with a bucket wheel excavator until it reaches the middle rock layer 2, put the excavated loess on the conveyor belt of the belt conveyor, and then put the excavated loess on the conveyor belt through the soil dumper. The loess is discharged into the outer dump; first, the gravel in the middle rock layer 2 is transported to the outer dump by a single-bucket truck (the gravel is the gravel in the middle rock layer), until the middle rock layer 2 After the formed pit has enough space (su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com