Preparation method for tea dust temmoku glaze

The technology of Tianmu glaze and tea powder is applied in the field of preparation of tea powder Tianmu glaze, which can solve the problems of discount of glaze artistic effect, and achieve the effects of large density and color range, elegant and soft leaf size, energy saving and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

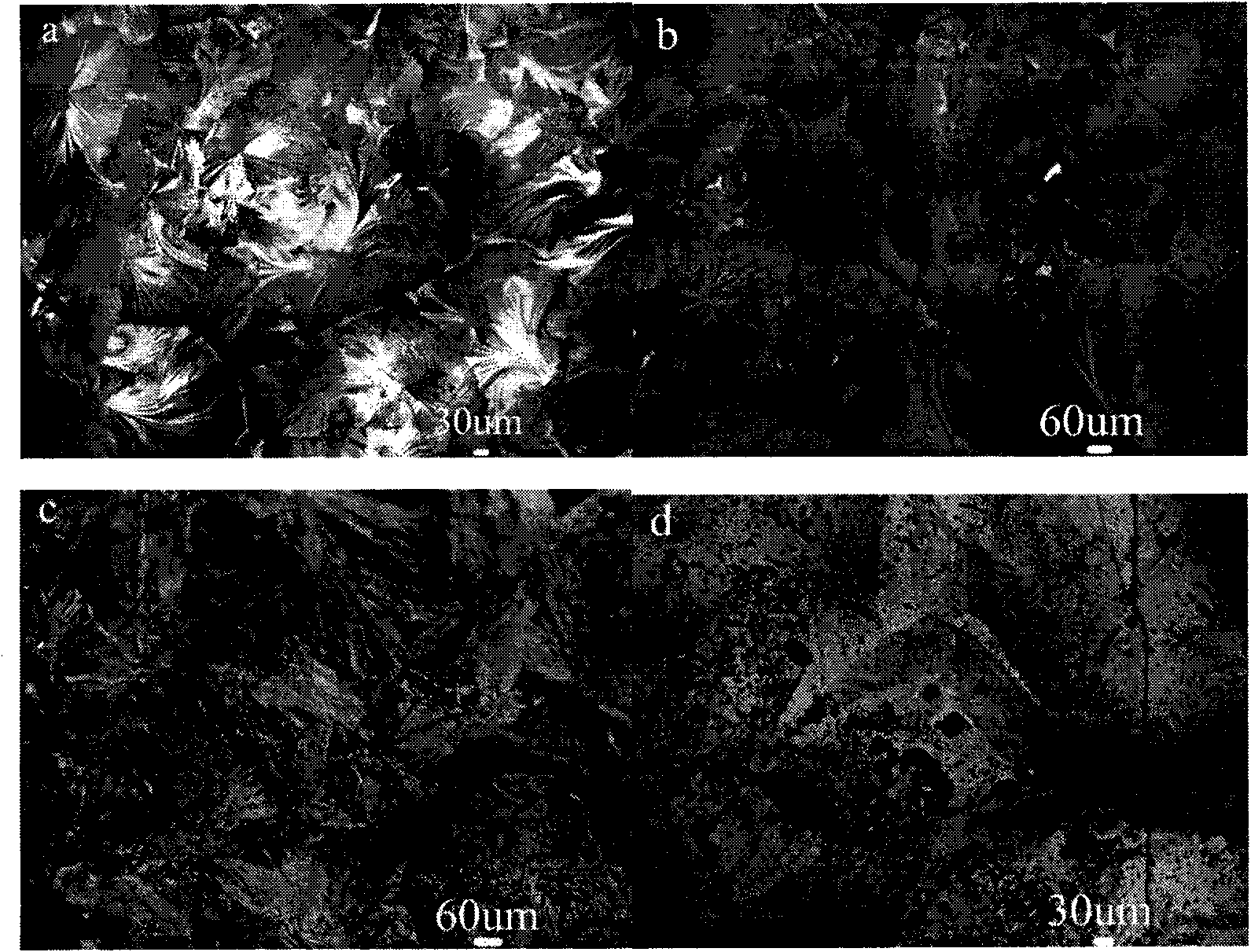

[0013] Embodiment 1, at first, by mass percentage, 10% loess, 40% feldspar, 10% quartz, 5% kaolin, 8% talc, 8% limestone, 0.5% calcium phosphate, 0.5% BaCO 3 Mix with 18% iron oxide; Secondly, add the sodium tripolyphosphate of mixture quality 0.2% and the cellulose of 0.5% in the mixture to obtain the mixture, then press the mixture: grinding ball: the quality of water=1: 2: 0.8 Ball milling and passing through a 200-mesh sieve to obtain the glaze; then, adjust the glaze to a specific gravity of 1.6-1.7g / cm 3 The glaze slurry is evenly coated on the green body; dried at room temperature; finally, the green body coated with the glaze slurry is fired at 1240°C to obtain the following: figure 1 (a) Eel yellow tea leaves end with Tianmu glaze.

Embodiment 2

[0014] Embodiment 2, at first, by mass percentage, 15% loess, 35% feldspar, 15% quartz, 3% kaolin, 10% talc, 5% limestone, 1% calcium phosphate, 0.5% BaCO 3 Mix with 15.5% iron oxide; Secondly, add the sodium tripolyphosphate of mixture quality 0.2% and the cellulose of 0.5% in the mixture to obtain the mixture, then press the mixture: grinding ball: the quality of water=1: 2: 0.8 Ball milling and passing through a 200-mesh sieve to obtain the glaze; then, adjust the glaze to a specific gravity of 1.6-1.7g / cm 3 The glaze slurry is evenly coated on the body; dried at room temperature; finally, the body coated with the glaze slurry is fired at 1200°C to obtain the ancient tea powder Tianmu famous glaze.

Embodiment 3

[0015] Embodiment 3, at first, by mass percentage, 20% loess, 32% feldspar, 18% quartz, 5% kaolin, 8% talc, 3% limestone, 1.5% calcium phosphate, 0.5% BaCO 3 Mix with 12% ferric oxide; Secondly, add the sodium tripolyphosphate of mixture quality 0.2% and the cellulose of 0.5% to obtain mixture in the mixture, then press mixture: milling ball: the quality of water=1: 2: 0.8 Ball milling and passing through a 200-mesh sieve to obtain the glaze; then, adjust the glaze to a specific gravity of 1.6-1.7g / cm 3 The glaze slurry is evenly coated on the green body; dried at room temperature; finally, the green body coated with glaze slurry is fired at 1180°C to obtain figure 1 (b) To the end of the black-bottomed green leaf tea leaves Tianmu glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com