Hydraulic arrangement mode sediment ejection structure

A hydraulic and pipeline technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of insurmountable efficiency and safety, inability to achieve high-efficiency sand discharge, and low sand discharge efficiency, so as to increase effective storage capacity and realize Effect of adjusting the relationship between water and sediment out of the reservoir and eliminating threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

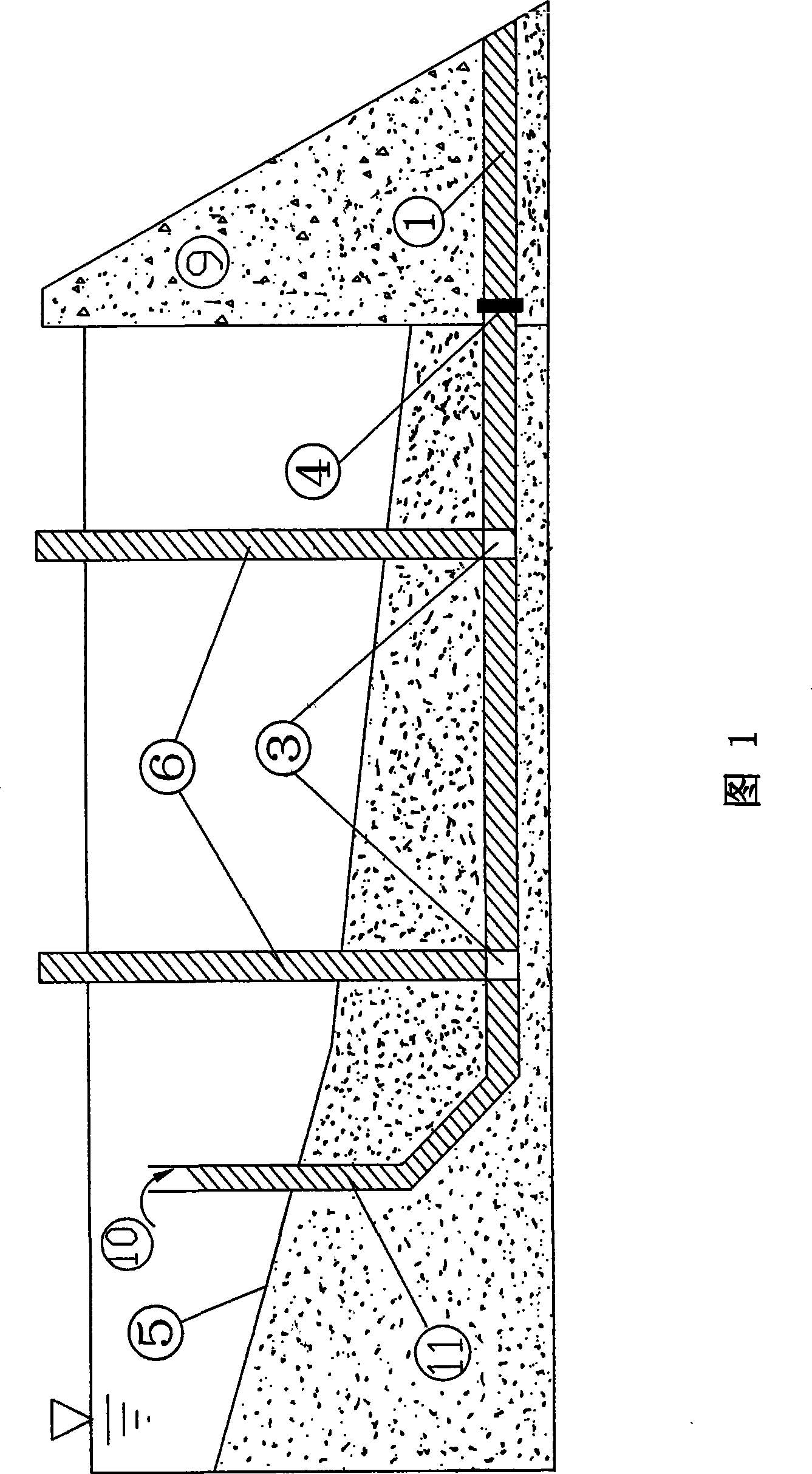

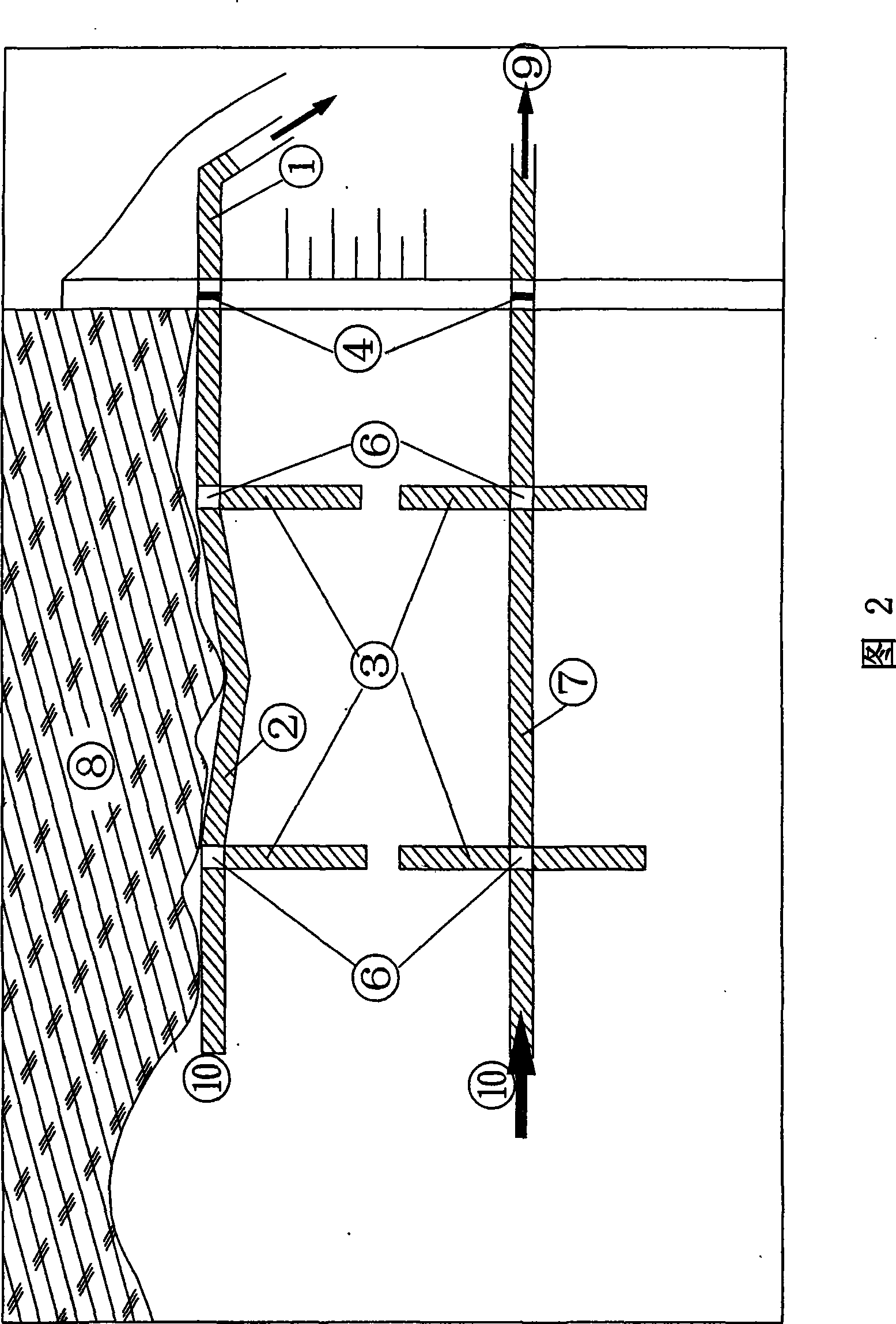

[0019] Embodiment: Referring to Fig. 1 and Fig. 2, in the figure, the tail end of the sand discharge pipeline of the hydraulic arrangement type sand discharge structure is connected with the bottom hole or tunnel 1 of the dam body 9, and a gate valve 4 is set to control the flow and discharge sand The head end of the pipeline extends upstream, and an upwardly curved pipe section is provided at the end, and the upper port 10 of the curved pipe section is higher than the expected sediment deposition surface 5 .

[0020] The quantity of the sand discharge pipeline is two, wherein a sand discharge pipeline 2 is laid on the bank 8 reservoir bottom, and another sand discharge pipeline 7 is laid on the middle reservoir bottom. And, two branch pipes 3 are arranged on one side of the sand discharge pipeline 2, two gate wells 6 are arranged on the upper side pipe wall, and control valves are arranged in the gate valve 6 wells; the two side pipe walls of the sand discharge pipeline 7 Two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com