Method for detecting guide waves of steel storage tank bottom plate

A technology of storage tank bottom plate and detection method, applied in the field of ultrasonic measurement and piping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

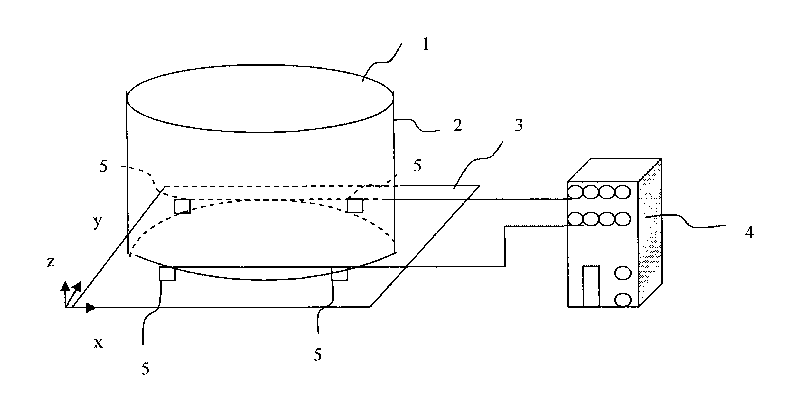

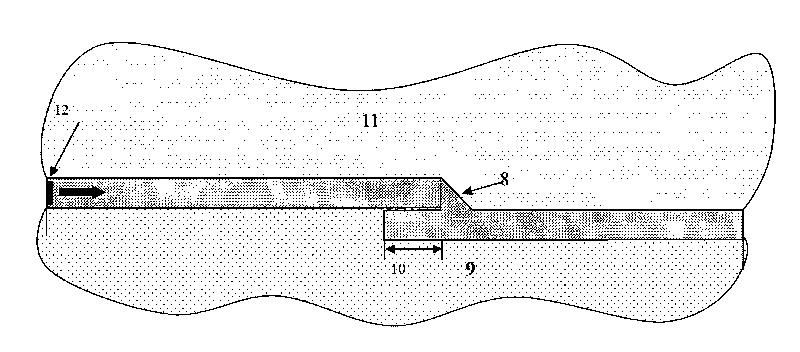

[0042] Embodiment. This example is in Fangshan-5000m 3 Methods of testing on crude oil storage tanks. The tank is a vault tank, with a fixed tank roof 1 on the tank wall 2 with an outer diameter of 24m and a height of 11m, a storage tank bottom plate 3 with an outer diameter of 26m and a thickness of 20mm, and a laminated section 10, and a storage tank bottom plate 3 Down is wet sand 9, and oil storage 11 is arranged in the tank (see image 3 ).

[0043] First select 4 suitable ultrasonic probe arrays 5, distribute the probe arrays 5 symmetrically along the storage tank bottom plate 3, and clean or derust the surface of the storage tank bottom plate 3 where the probe arrays 5 need to be placed, so as to enhance the detection effect. Leave enough space for probe array 5 and wedge installation (see figure 2 ).

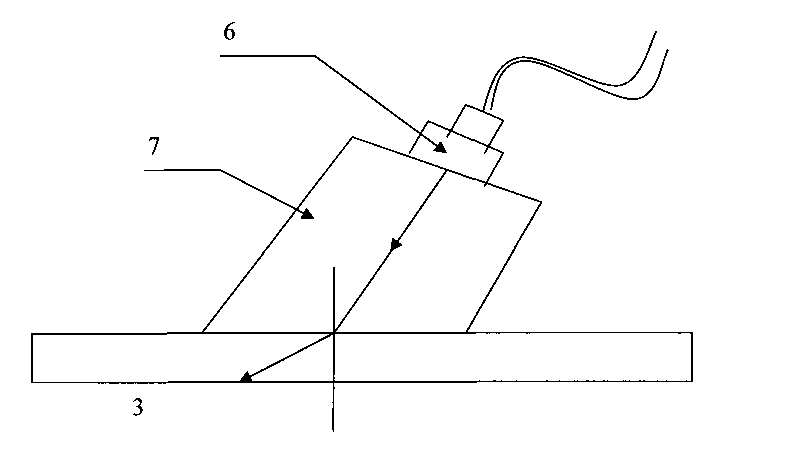

[0044]Piezoelectric ceramic sensors are used as transducers, and two transducers are installed in each module, which are respectively used to excite and receive guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com