Air cooling condenser high-pressure door type or cantilever type track automatic cleaning device

An air-cooled condenser and automatic cleaning technology, which is applied in the direction of cleaning heat transfer devices, washing, lighting and heating equipment, etc., can solve the problems of low automation, large investment in heat dissipation systems, complicated design, etc., and achieve high automation and cleaning High efficiency and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

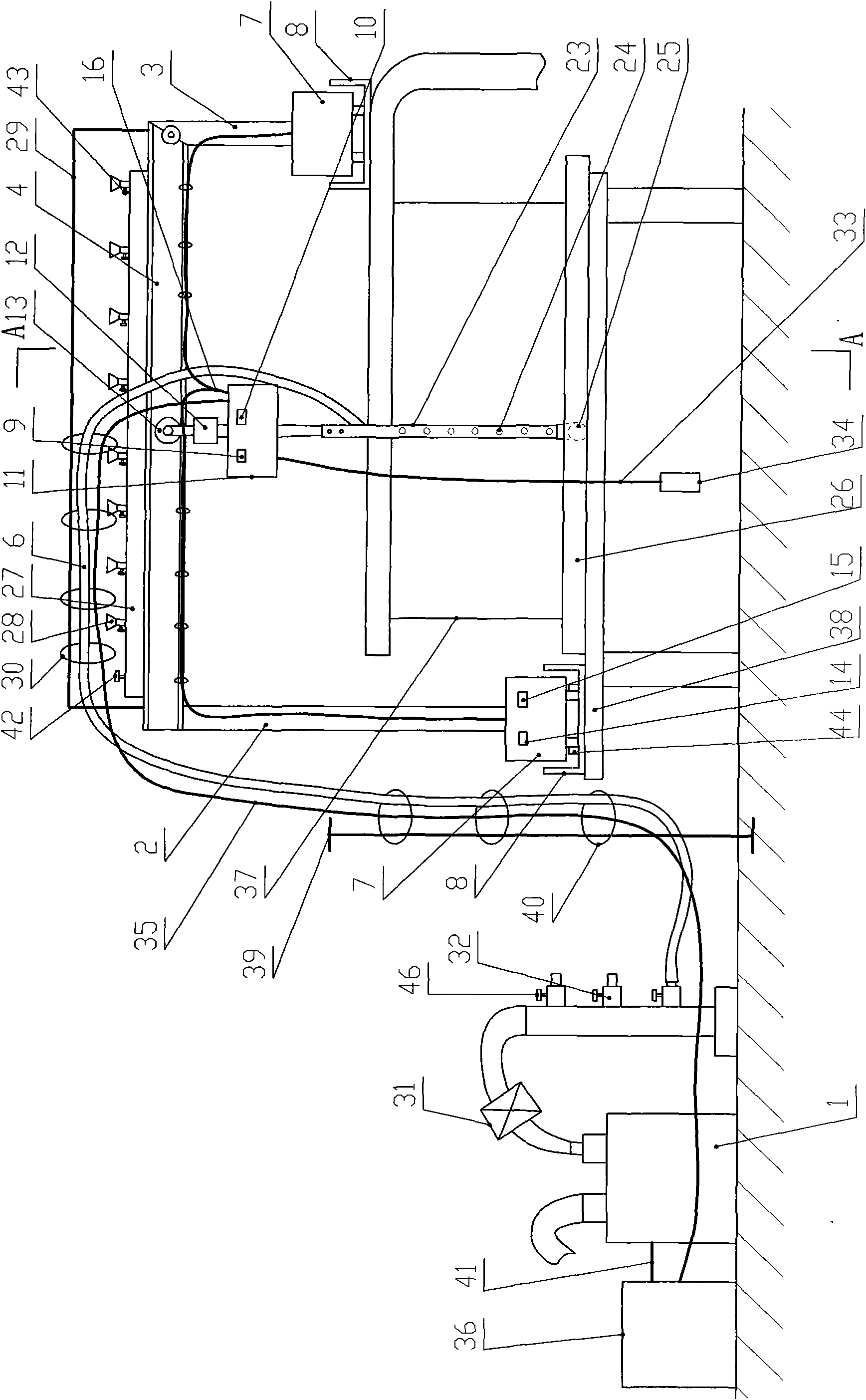

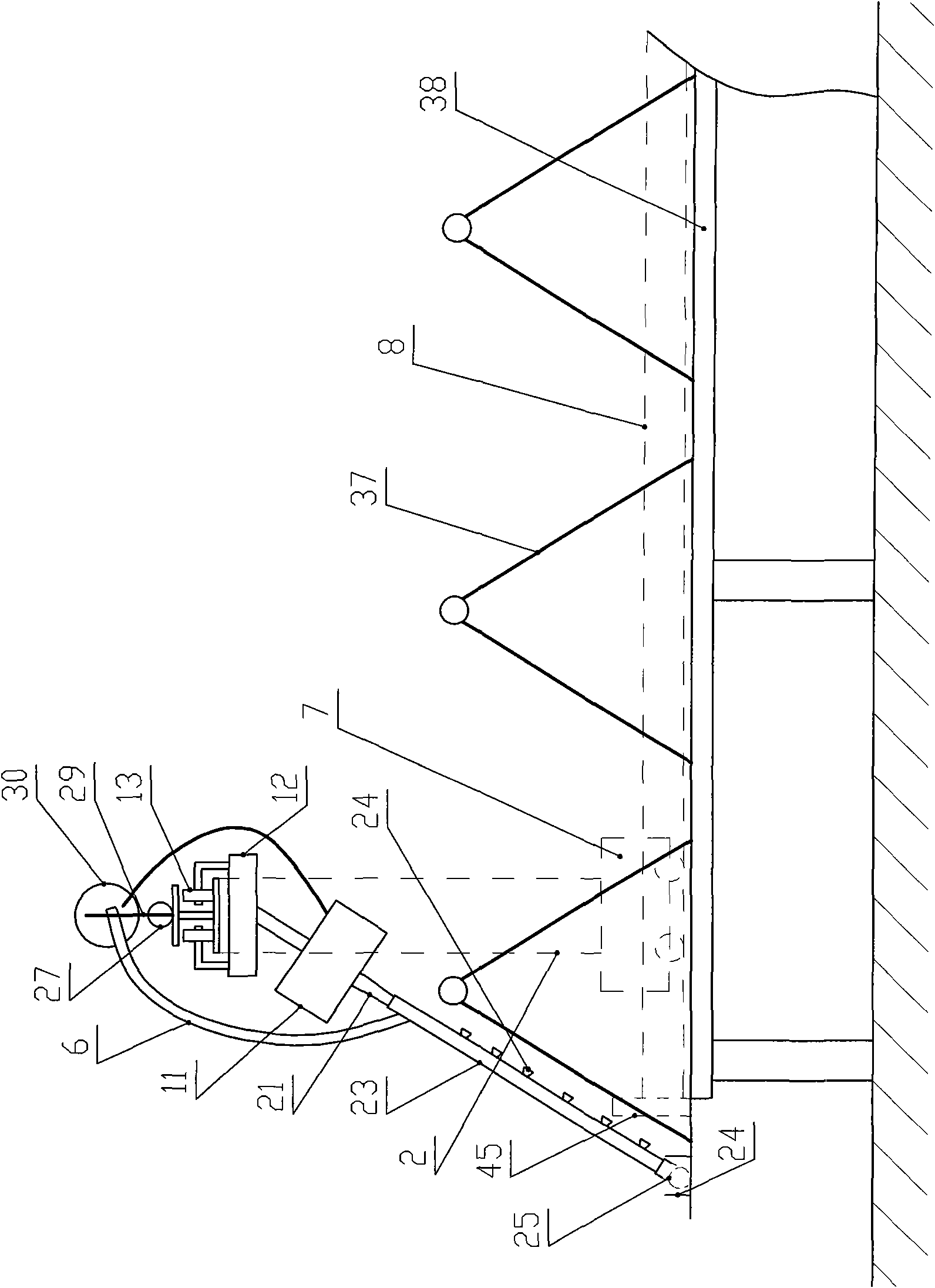

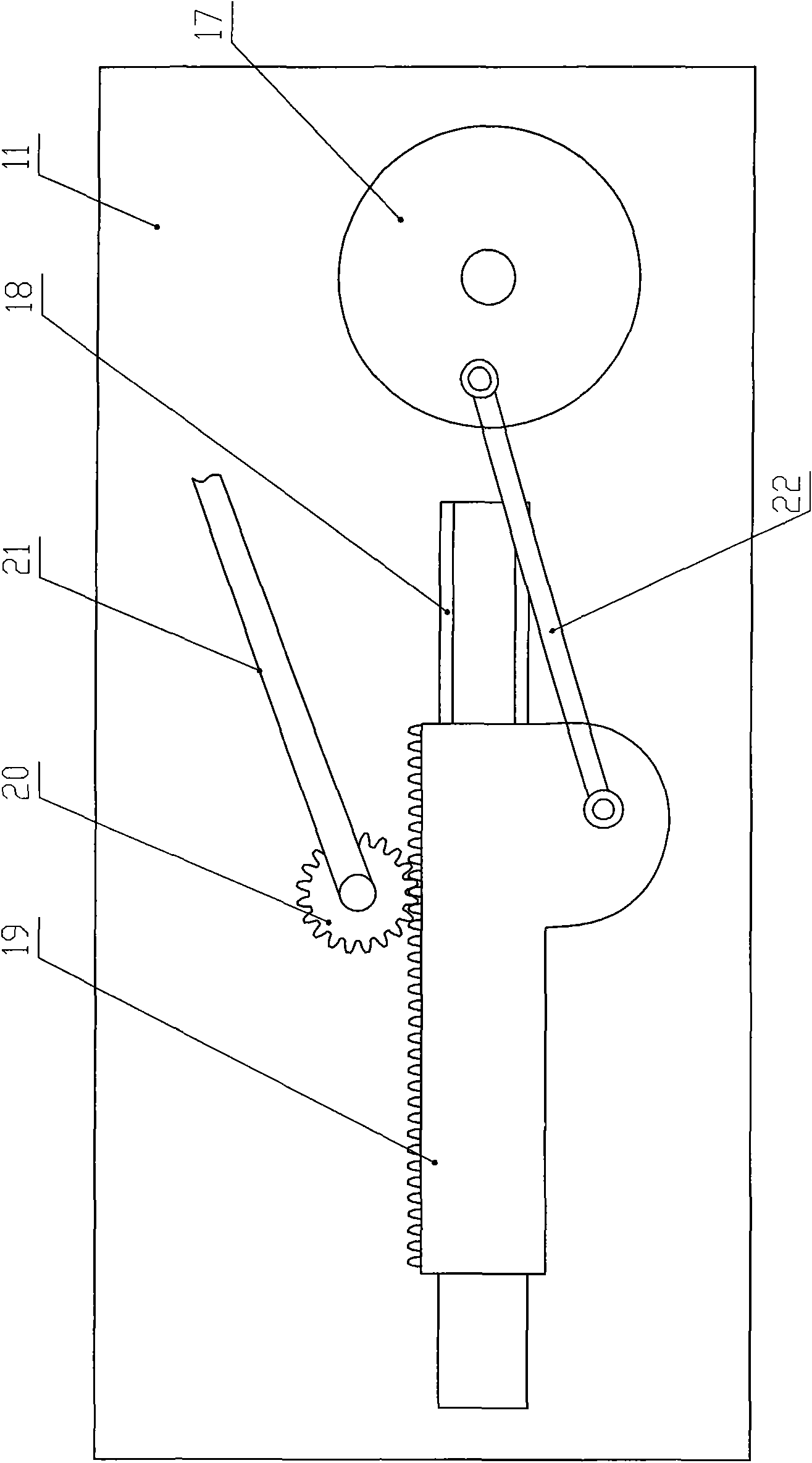

[0041] Such as Figure 1 ~ Figure 3 As shown, the air-cooled condenser high-pressure door-type or cantilever-type track automatic cleaning device of the present invention includes a high-pressure water jet cleaning machine 1 and a support, and the support is a door-type structure consisting of two vertical columns 2, a column 3 and a horizontal The crossbeam 4 is composed of a cleaning device assembly that is slidably connected to the crossbeam 4. The high-pressure water jet cleaning machine 1 is connected with the cleaning device assembly through a high-pressure water pipe 6, and the high-pressure water pipe 6 is a high-pressure hose. The length of the column 2 is greater than that of the column 3, the column 3 and the crossbeam 4 are hingedly arranged, the lower ends of the column 2 and the column 3 are equipped with a set of track traveling machine 7, and the lower ends of the column 2 and the column 3 are respectively connected by the rolling fit of the track walking machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com