Multifunctional rotary spraying-type washing device and method

A cleaning device and a spraying technology, which is applied in the field of industrial parts cleaning, can solve problems such as difficulty in meeting cleaning requirements, substandard cleaning cleanliness, and affecting product quality, and achieve shortened cleaning time, good cleaning effect, and high cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

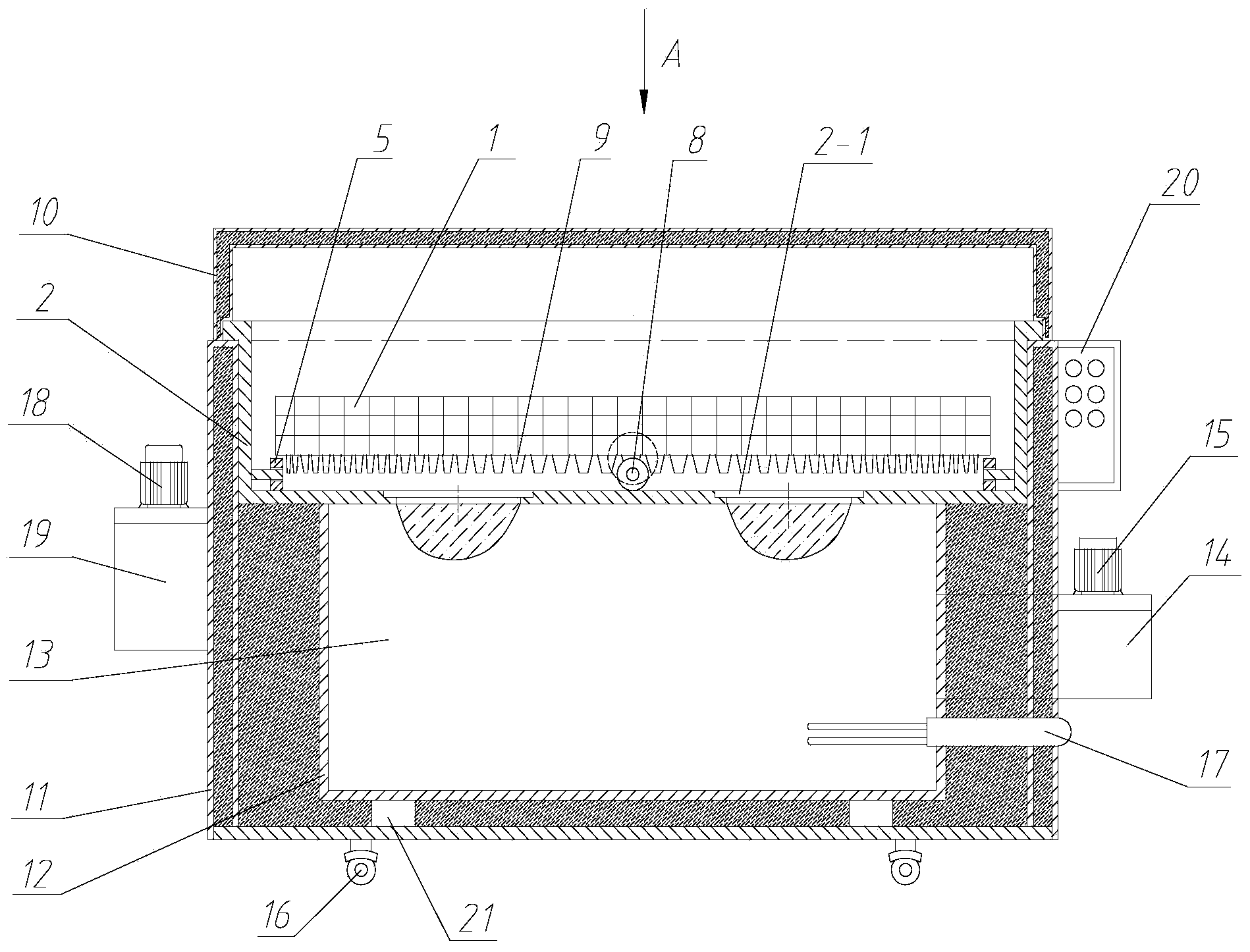

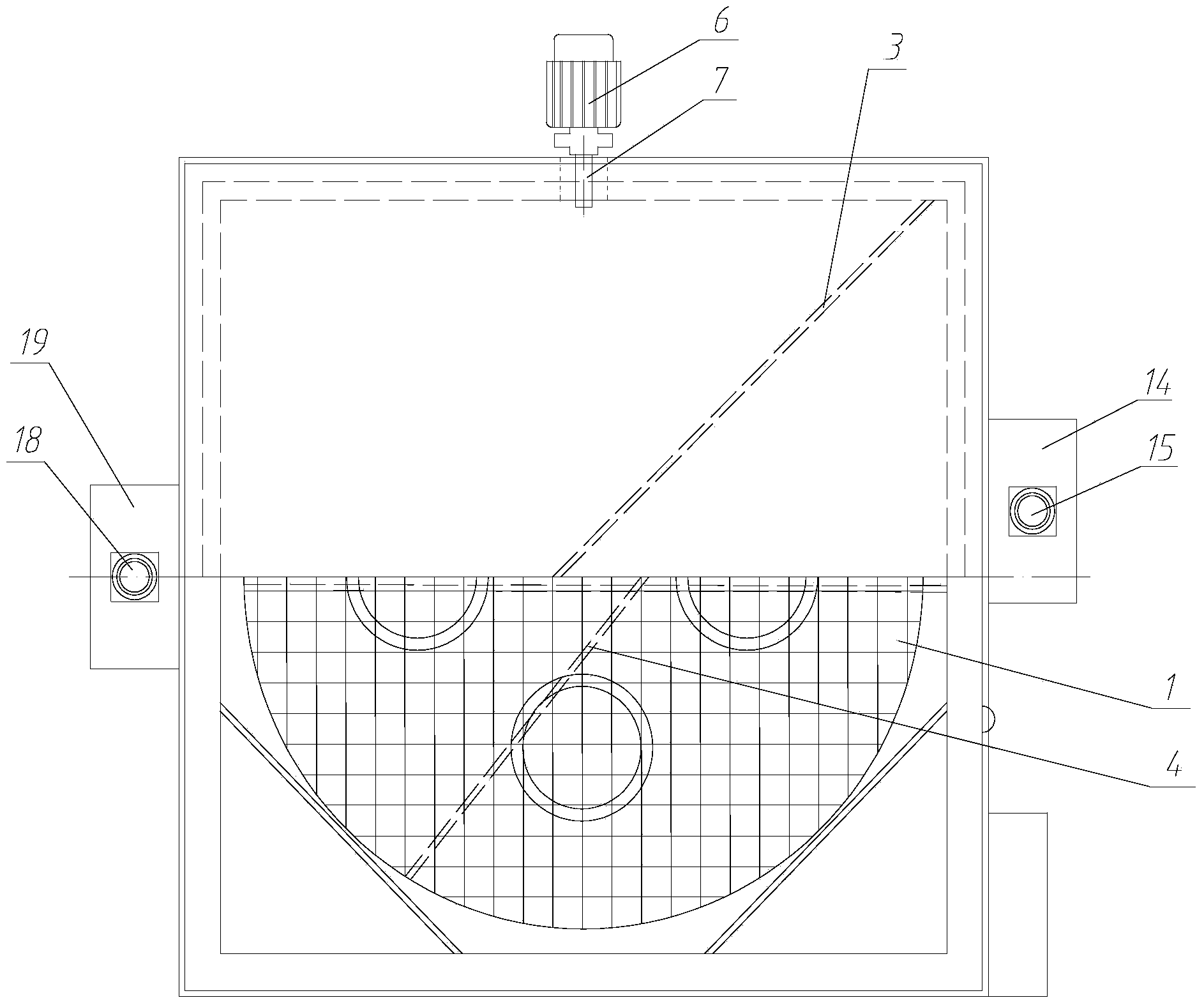

[0038] In this embodiment, a multifunctional rotary spray cleaning device, such as figure 1 or figure 2 As shown, it includes a cleaning box and a cleaning mechanism, and the cleaning mechanism is arranged in the cleaning box; the cleaning mechanism includes a cleaning basket 1, a filter layer 2, a cleaning basket rotation drive assembly, an upper nozzle pipe 3 with a nozzle, and a lower nozzle with a nozzle Tube 4 (as figure 2 As shown), the filter layer is fixed in the cleaning box, the cleaning basket is set above the filter layer, the bottom of the cleaning basket is connected with the rotating drive assembly of the cleaning basket, the upper spray pipe is set above the cleaning basket, and the lower spray pipe is set between the cleaning basket and the filter layer Between; the upper spray pipe and the lower spray pipe are externally connected to the cleaning liquid supply mechanism.

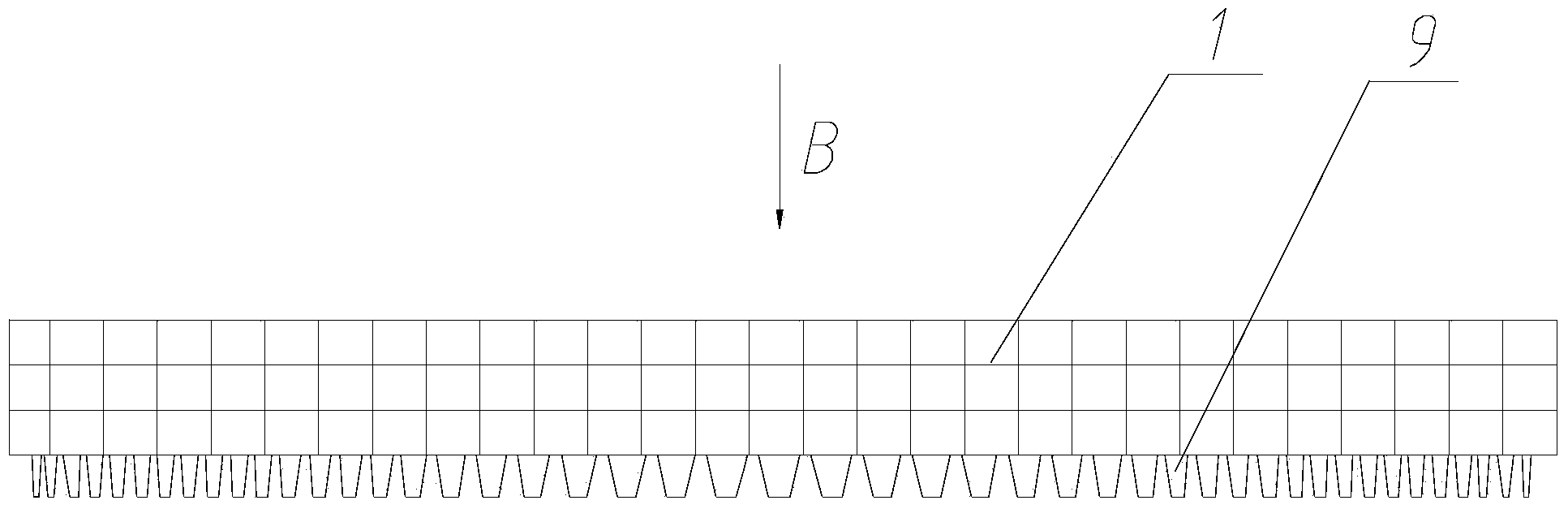

[0039] Such as Figure 5 or Figure 6 As shown, the filter layer is a hollow rect...

Embodiment 2

[0052] In this embodiment, a multifunctional rotary spray cleaning device, such as Figure 7 Shown, compared with embodiment 1, its difference is:

[0053] The bottom of the outer box is equipped with universal wheels 16, which facilitates the movement of the entire cleaning device and facilitates the replacement of workplaces;

[0054] There is a heater 17 in the inner box, which can directly control the start and stop of the heater through the controller and sensor, so as to ensure that the temperature of the cleaning liquid in the liquid storage tank is kept within the set range, and the heater passes through the outer box and the liquid storage. The through hole of the pool leads to the liquid storage pool, and a sealing device is installed between the heater and the through hole;

[0055] The box wall of the outer box is filled with heat insulating material, the box cover is filled with heat insulating material, and the space between the inner box and the outer box is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com