Pulse circulation cleaning device for heat exchanger and using method thereof

A technology of pulse circulation and cleaning equipment, which is applied in the direction of cleaning heat transfer equipment, flushing, lighting and heating equipment, etc., and can solve the problems of not being able to maximize the clean and efficient operation of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

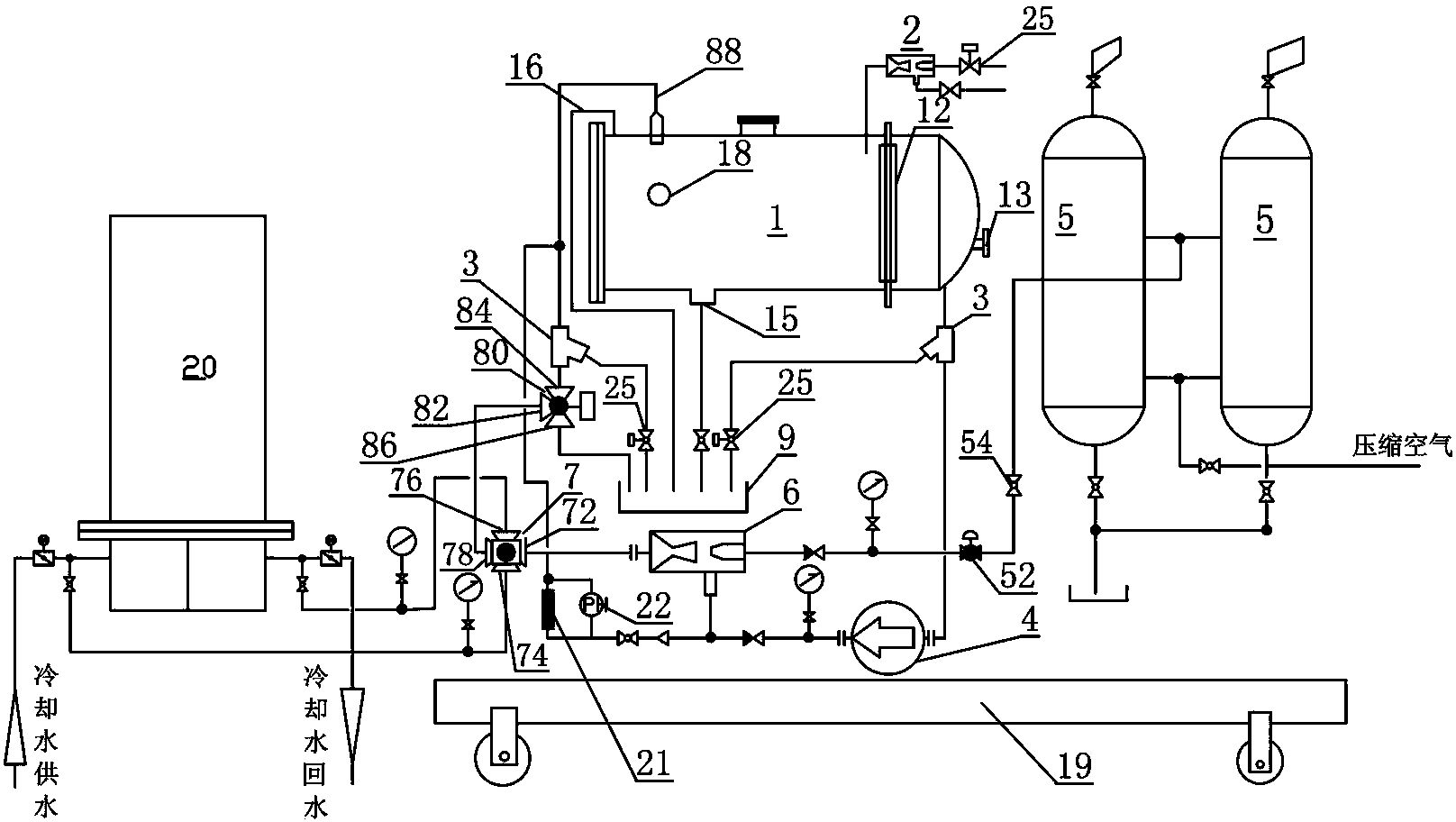

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

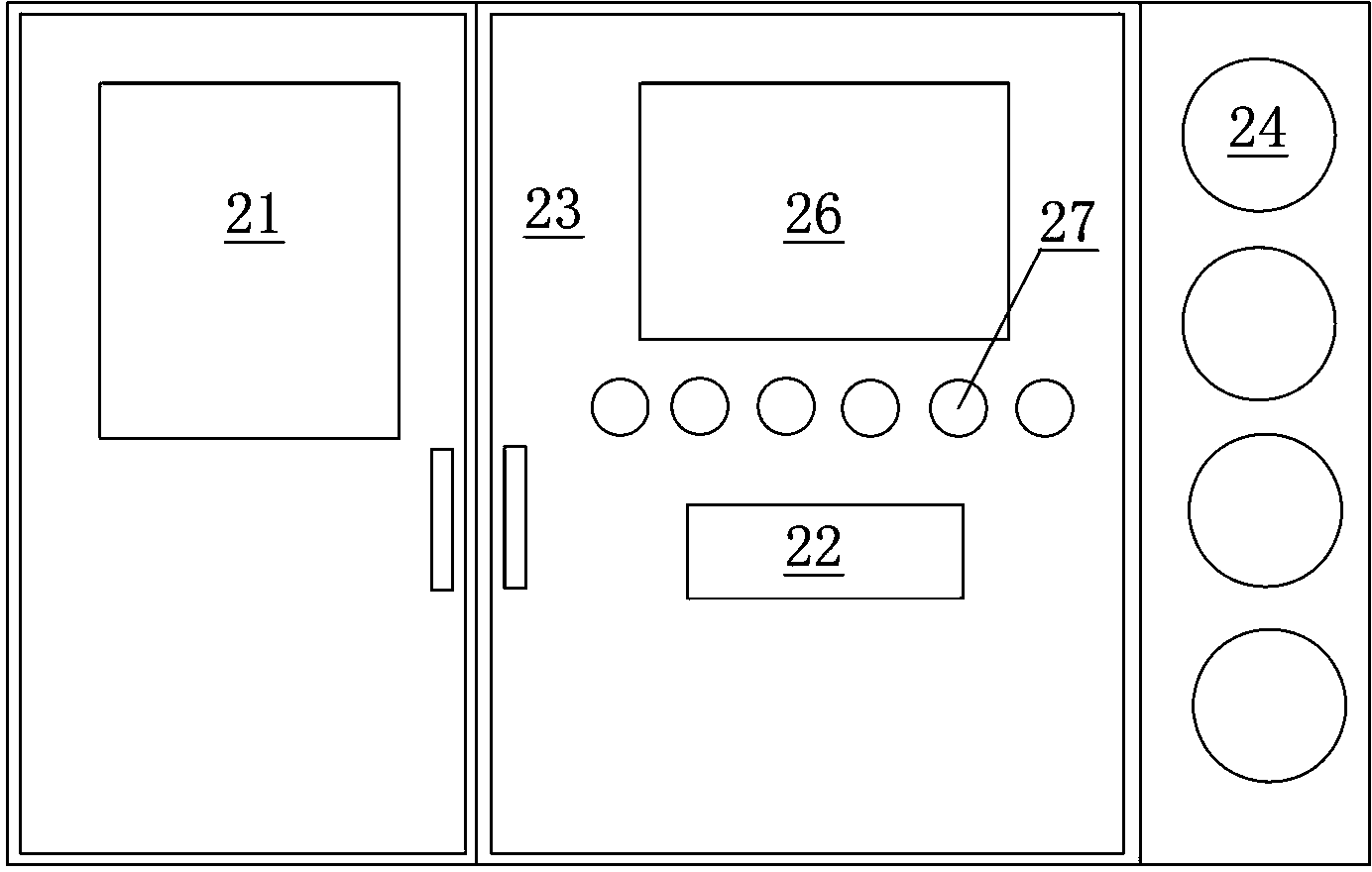

[0041] see figure 1 and figure 2 , The embodiment of the present invention provides a heat exchanger pulse cycle cleaning device, which includes a cleaning tank 1, a water-liquid mixer 2, two filters 3, a cleaning pump 4, two gas buffer tanks 5, a pulse generator 52, Gas-liquid mixer 6, switching valve 7, three-way discharge valve 8, water collector 9 and control unit (not labeled).

[0042] The water-liquid mixer 2 is connected to the liquid inlet pipe at the top of the cleaning tank 1, and provides water or cleaning liquid for the cleaning tank 1. The lower liquid pipe of the cleaning tank 1, the filter 3, and the cleaning pump 4 are sequentially connected in series.

[0043] The two gas buffer tanks 5 are fixed side by side on the side surface of the cleaning tank 1, and provide compressed gas for the cleaning device, and are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com