Cleaning agent for screw extruder and preparation method thereof

A screw extruder and cleaning agent technology, applied in the field of cleaning agents, can solve the problems of incomplete cleaning of carbon deposits, poor adaptability and high cost, and achieve the effects of fast cleaning speed, strong adaptability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

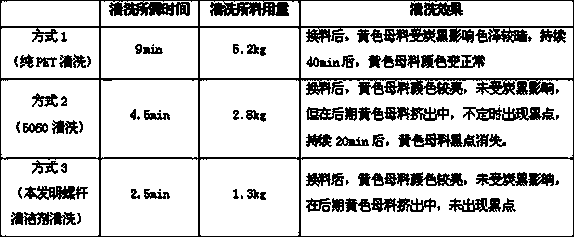

Image

Examples

Embodiment 1

[0035] 1) Add 60 parts by weight of fine brucite and 1 part by weight of sulfate ester into the WF-100 micro-powder machine, set the temperature of the micro-powder machine to 100°C, disperse and refine at a high speed of 1000rpm for 20 minutes, and the fine fiber powder aggregates Fully dispersed and refined, then add 5 parts by weight of sodium tetraborate decahydrate, and continue to activate for 5 minutes to obtain active microfiber powder;

[0036] 2) Add 30 parts by weight of serpentine and 5 parts by weight of itaconic anhydride grafted polypropylene wax with a molecular weight of 5000 to step 1), melt, disperse and mix for 10 minutes at a speed of 800 rpm, and discharge after the lubricant is completely melted and dispersed;

[0037] 3) Put the material obtained in step 2) into a conical screw extruder with a screw diameter of 65mm and a screw length-to-diameter ratio of 25:1. The temperature set from the feed end to the discharge end is: controlled by feeding section 1...

Embodiment 2

[0040] 1) Add 50 parts by weight of fine attapulgite and 1 part by weight of sodium dioctyl sulfosuccinate into the WF-100 micro-powder machine, set the temperature of the micro-powder machine to 100°C, and disperse and refine at a high speed of 800 rpm for 10 minutes. The microfiber powder bundle is fully dispersed and refined, and then 8 parts by weight of polyoxyalkylene-polysiloxane polymer is added, and the activation is continued for 3 minutes to obtain active microfiber powder;

[0041] 2) Add 20 parts by weight of mica and 4 parts by weight of maleic anhydride grafted polyethylene wax with a molecular weight of 4000 to step 1), melt, disperse and mix at a speed of 800 rpm for 10 minutes, and discharge after the lubricant is completely melted and dispersed;

[0042] 3) Put the material obtained in step 2) into a conical screw extruder with a screw diameter of 50mm and a screw length-to-diameter ratio of 25:1. The temperature set from the feed end to the discharge end is:...

Embodiment 3

[0045] 1) Put 55 parts by weight of fine gypsum whiskers and 2 parts by weight of lauric acid in a WF-100 micro-powder machine, set the temperature of the micro-powder machine to 100°C, disperse and refine at a high speed of 800 rpm for 10 minutes, and the fine fiber powder is aggregated Fully disperse and refine, then add 6 parts by weight of sodium polyacrylate, and continue to activate for 3 minutes to obtain active microfiber powder;

[0046] 2) Add 20 parts by weight of montmorillonite and 5 parts by weight of itaconic anhydride grafted polyethylene wax with a molecular weight of 5000 to step 1), melt, disperse and mix at a speed of 500 rpm for 15 minutes, and discharge after the lubricant is completely melted and dispersed;

[0047] 3) Put the material obtained in step 2) into a conical screw extruder with a screw diameter of 45mm and a screw length-to-diameter ratio of 20:1. The temperature set from the feed end to the discharge end is: controlled by feeding section 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com