Patents

Literature

45results about How to "Thorough cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

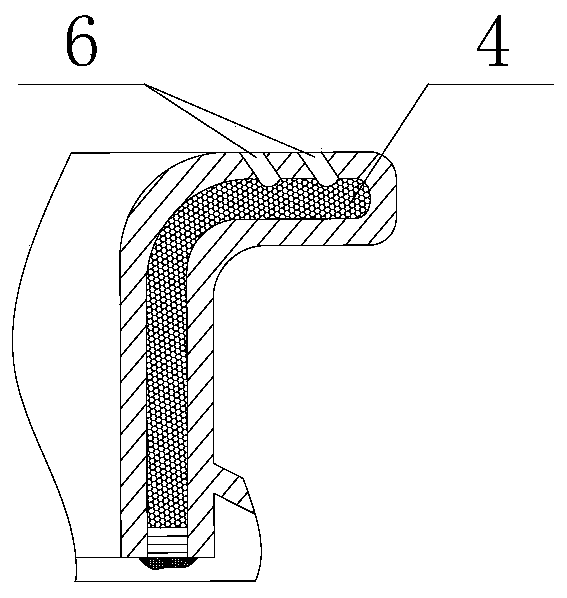

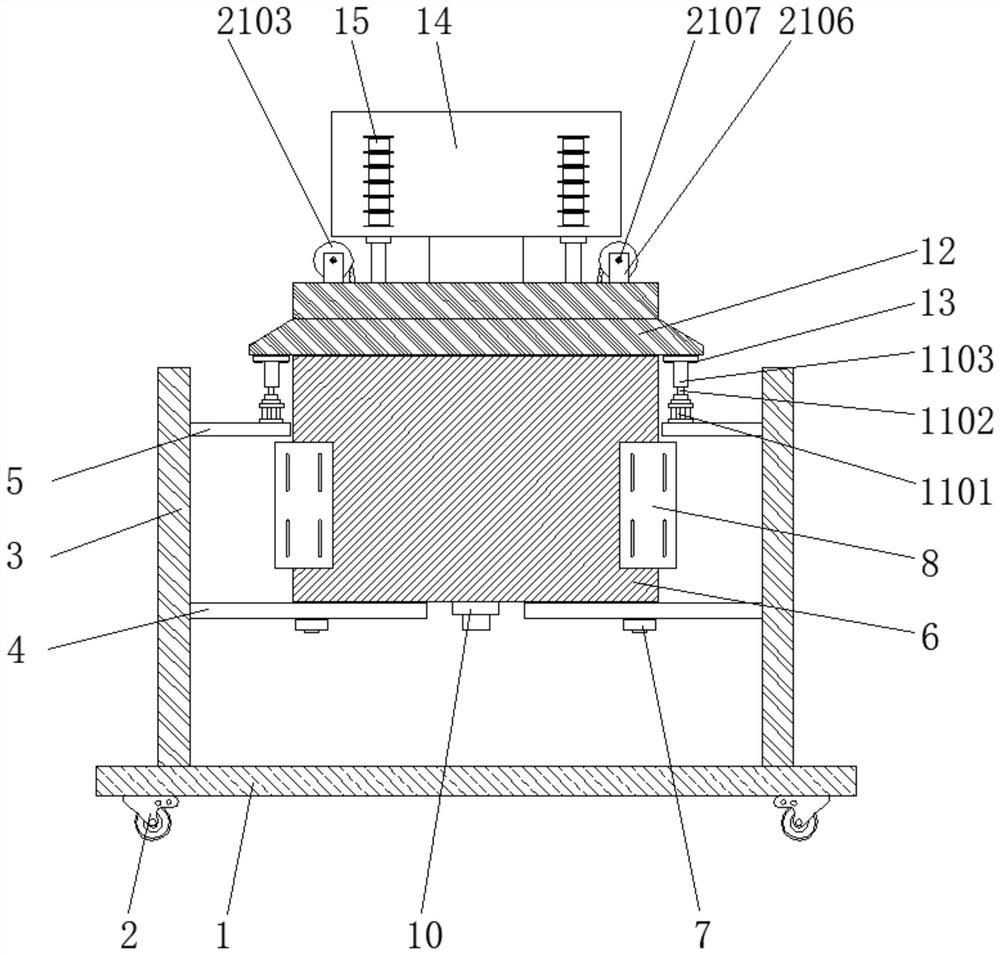

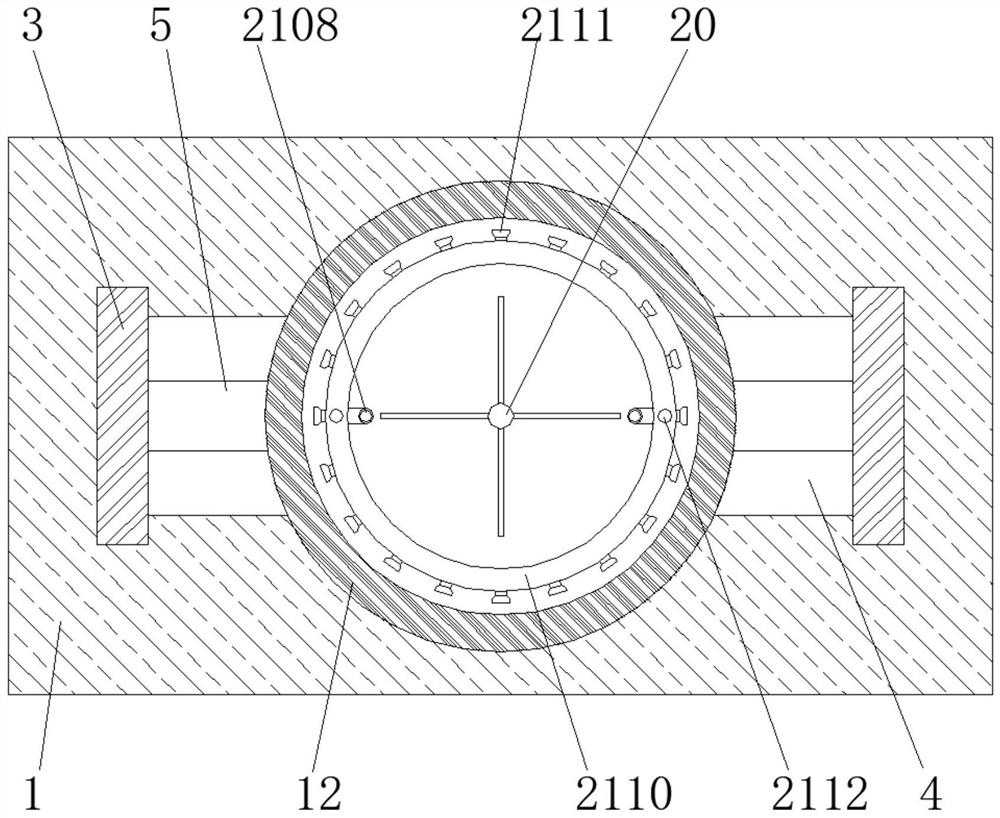

Automatic excrement collecting device

InactiveCN102961226APrevent side leakageAvoid giving birthMedical transportControl systemEngineering

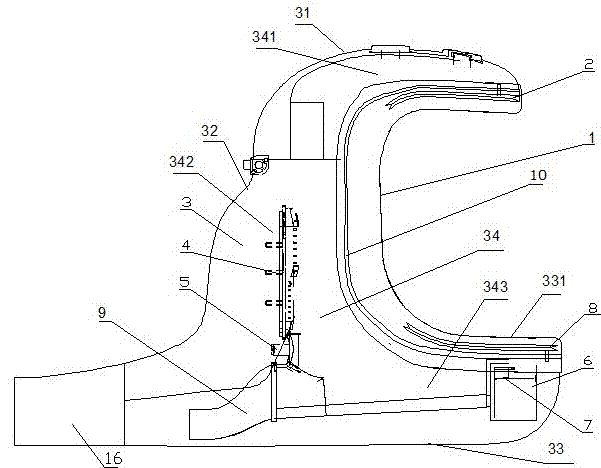

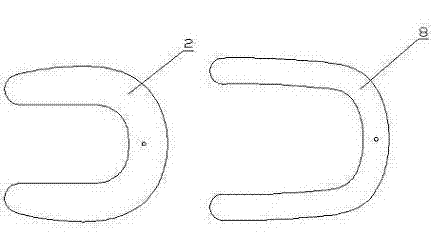

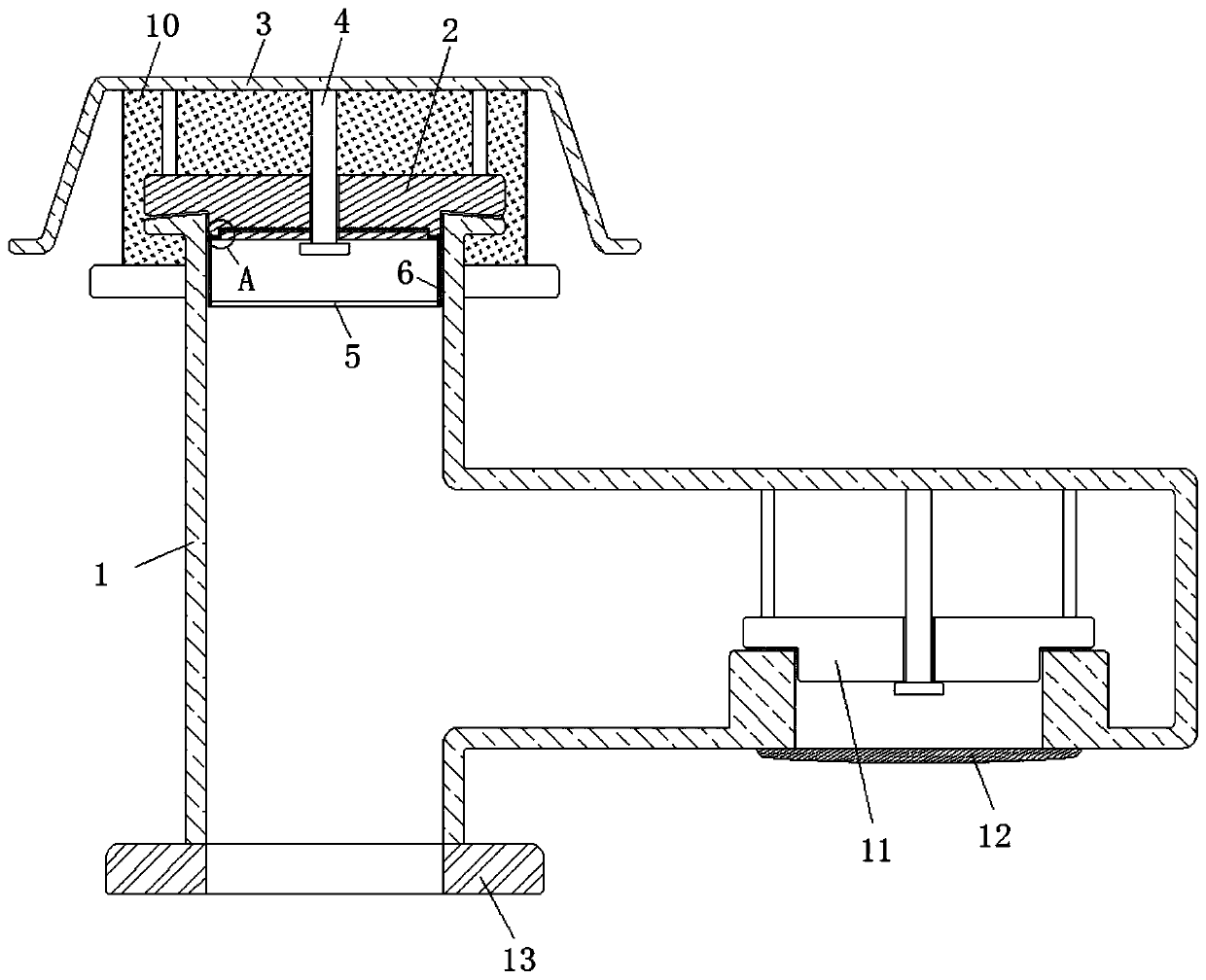

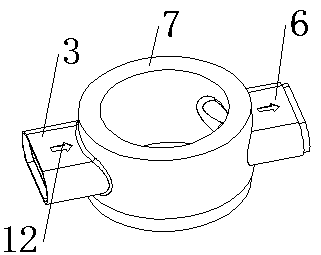

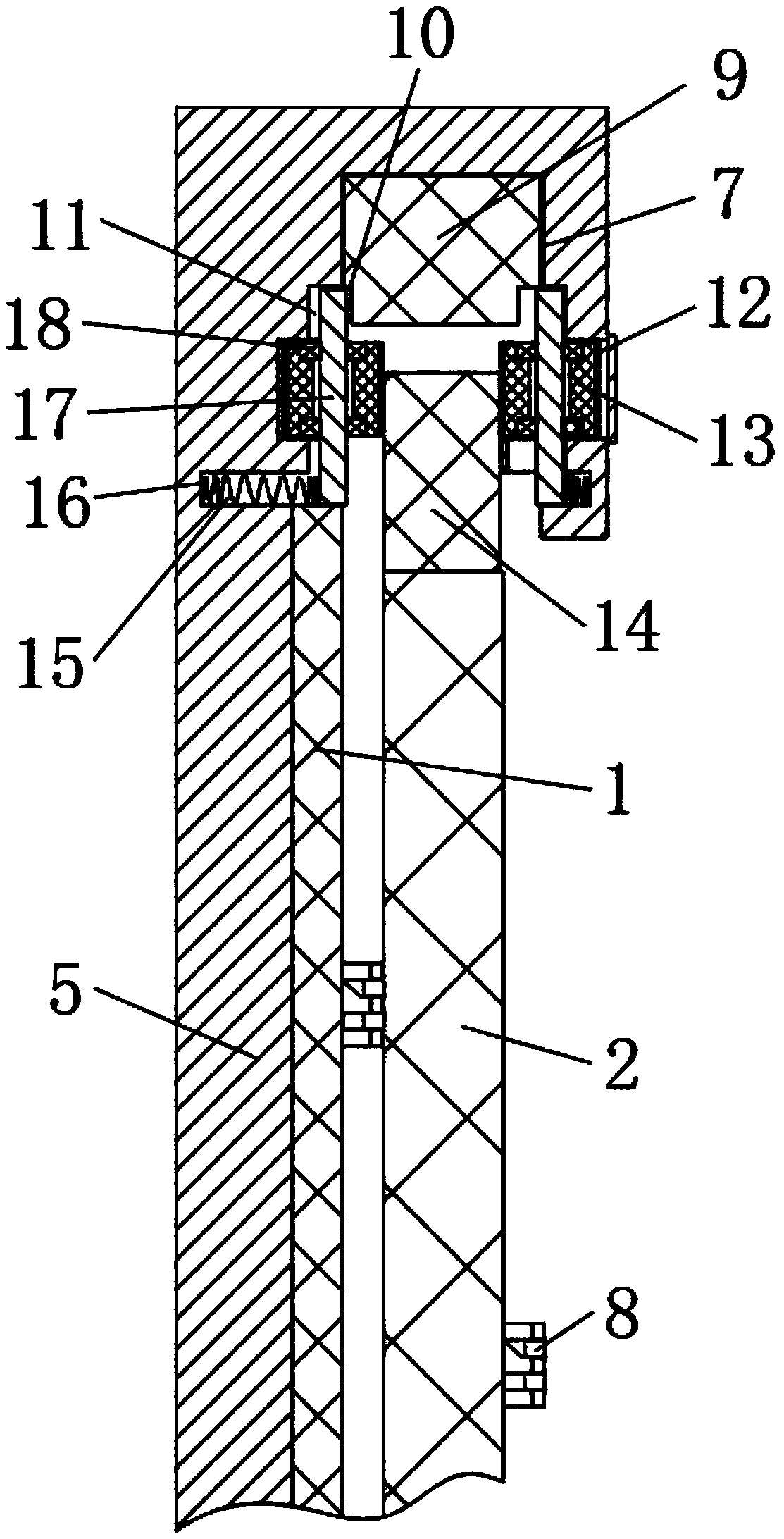

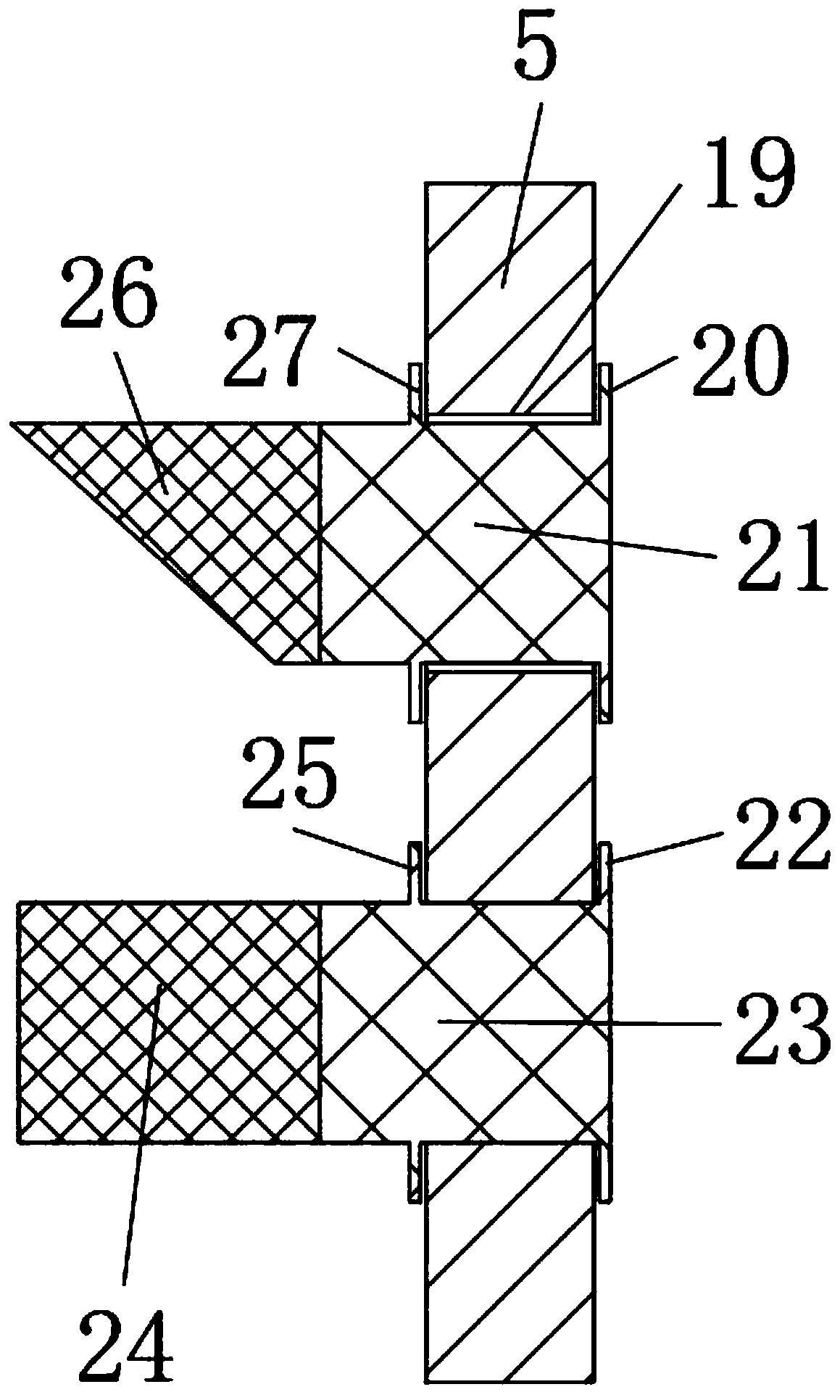

The invention belongs to a medical nursing device, in particular to an automatic excrement collecting device aiming at disabled patients. The device comprises a control system and an excrement collecting device, wherein the excrement collecting device having a C-shaped side comprises an upper portion, a side portion and a lower portion, which are respectively contacted with the human abdomen, the crotch and the hip; a concave cavity is arranged inside the excrement collecting device, the concave cavity is communicated with an excrement treatment pipe, the excrement collecting device is provided with a C-shaped self-adaptive integrated sealing pad at the part contacted with the human body, and the self-adaptive integrated sealing pad is provided with an upper U-shaped airbag at the upper part and a lower U-shaped airbag at the lower part. In the working process of the automatic excrement collecting device provided by the invention, a proper amount of air is filled through the upper and the lower airbags, so that the self-adaptive integrated sealing pad is tightly contacted with the patient to prevent lateral leakage of the excrement.

Owner:WUXI YOUER MEDICAL TECH

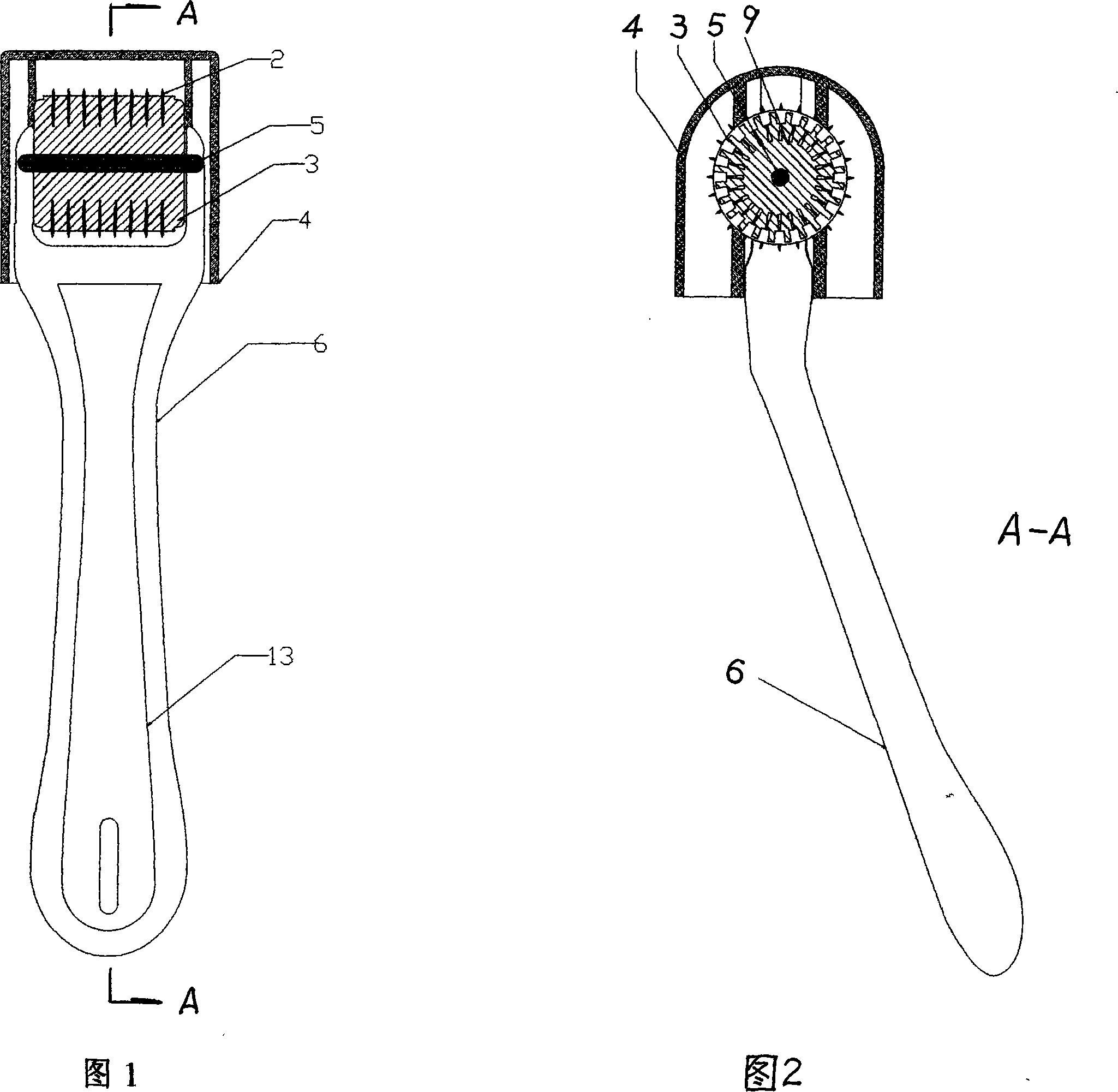

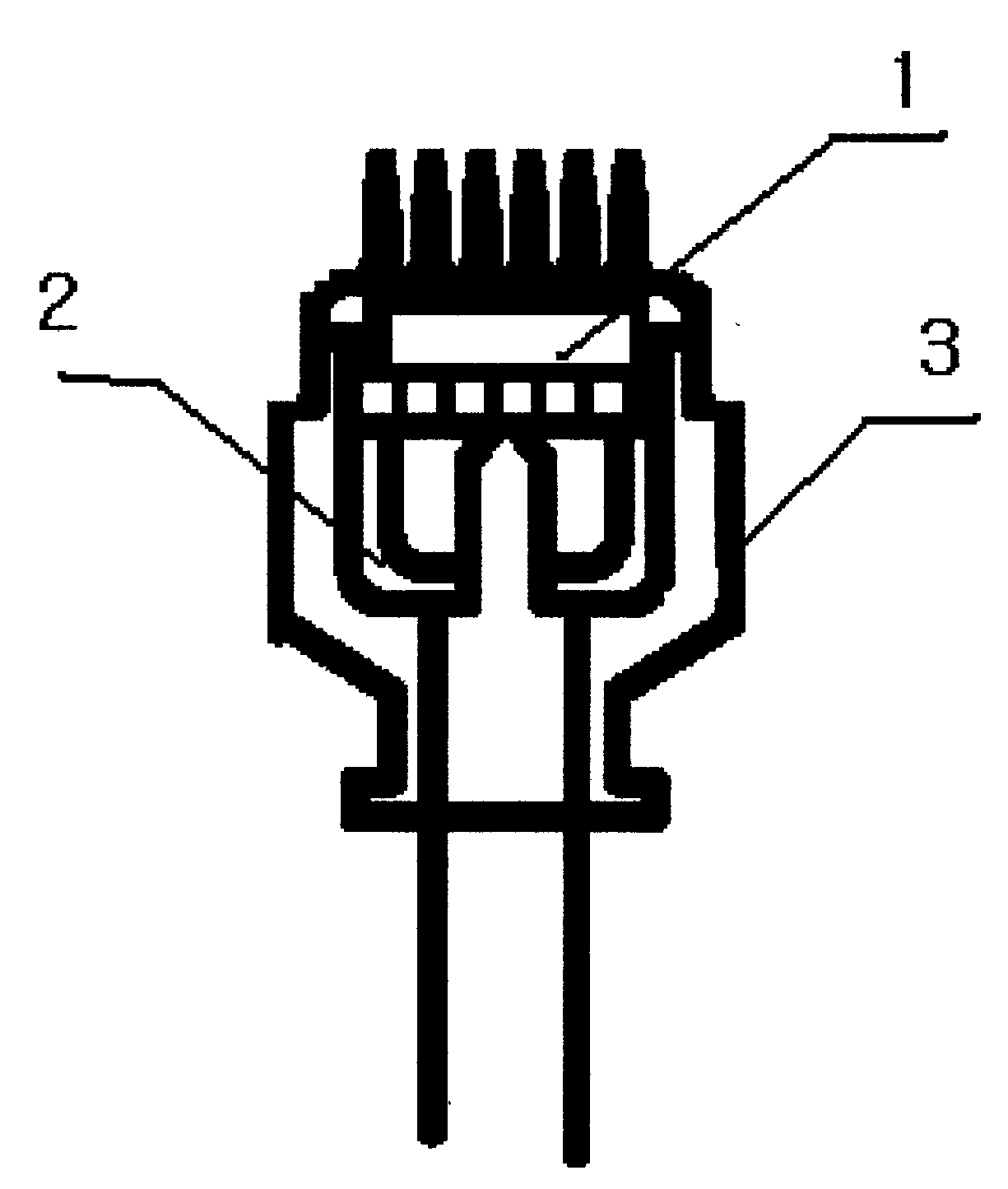

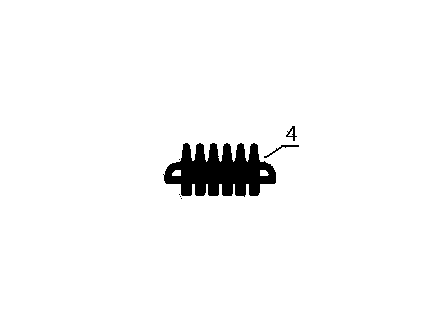

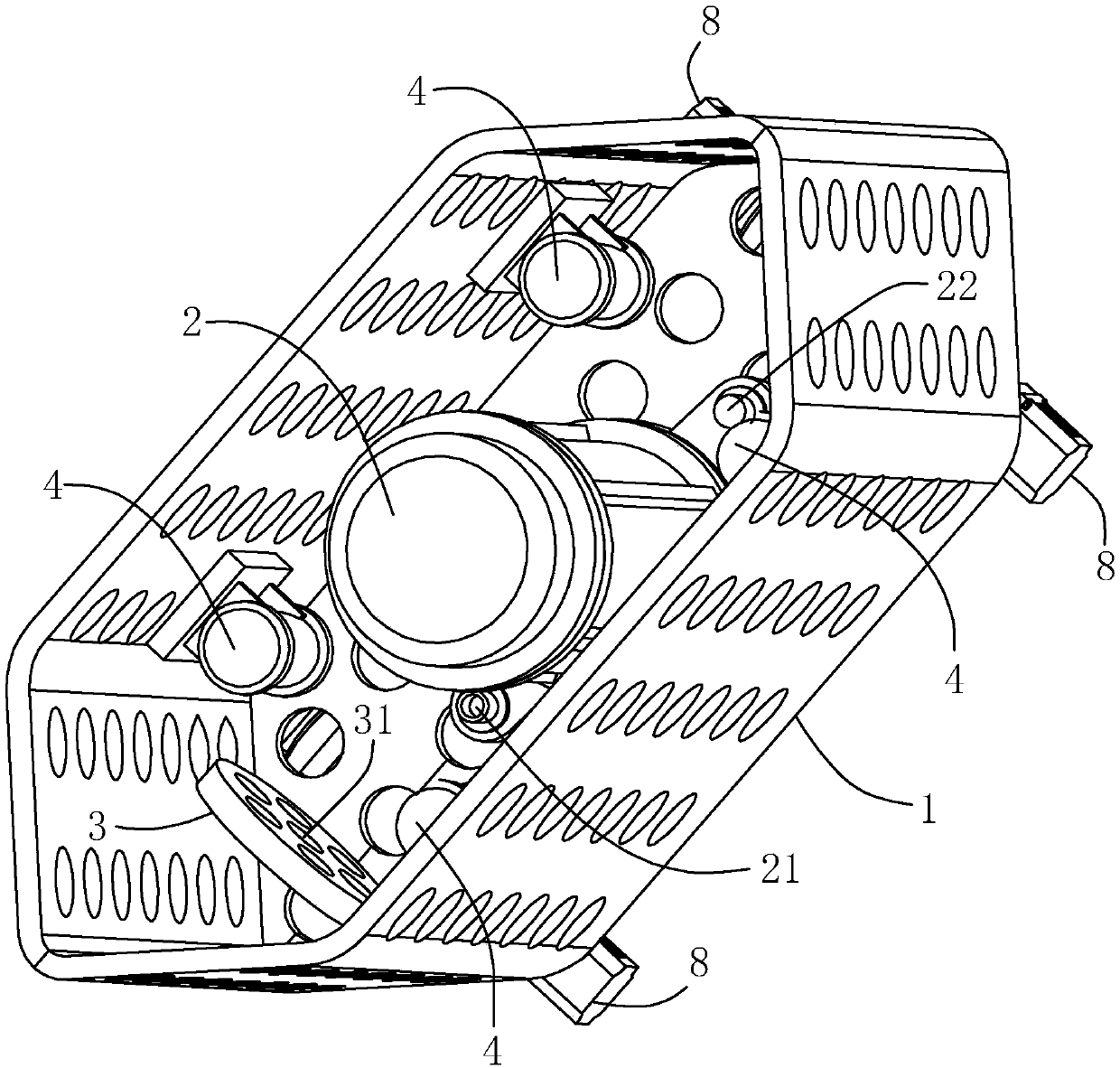

Microacupunoture massager and producing method thereof

InactiveCN101194847AReduce gapIncrease the number of repeated useSurgerySuction-kneading massageBiotechnologyApparatus instruments

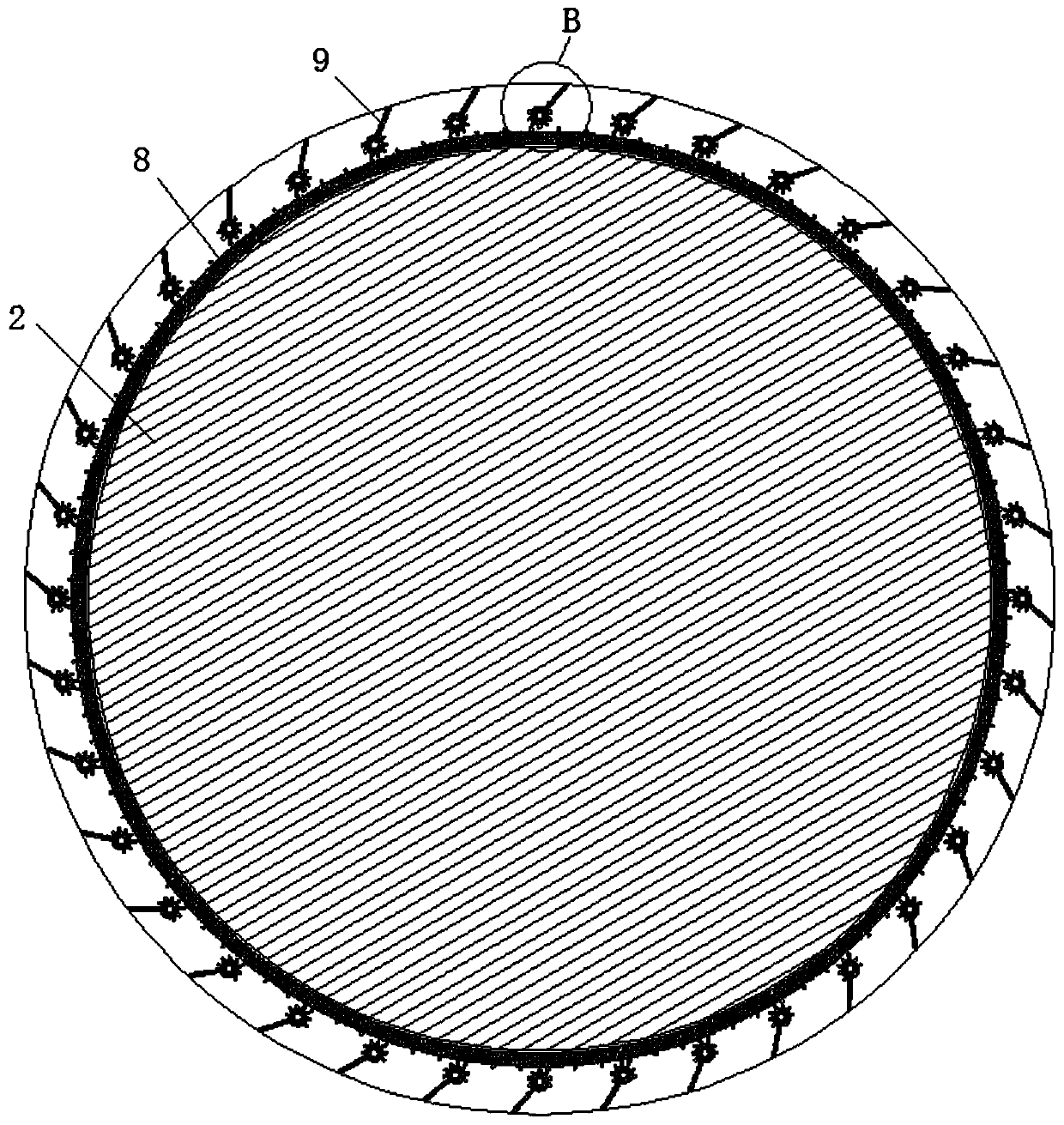

The invention relates to a micro-needle massager and production method of the micro-needle massager, belonging to the technical field of beauty medical appliances. The invention is constituted by the connection of a handle, a wheel shaft and a needle wheel which is fixed on the handle through the wheel shaft, wherein the needle wheel is constituted by a core wheel and a faller gill which is coated on the outer wall of the core wheel, and the faller gill is densely covered by micro-needles. The invention has simple structure, smooth and regular shape, more sanitation and convenience in the process of use, and complete disinfection and cleaning. The production method of the invention is simple and fast, which reduces the production cost. And the product of the invention significantly increases beauty effect.

Owner:沈忠忠

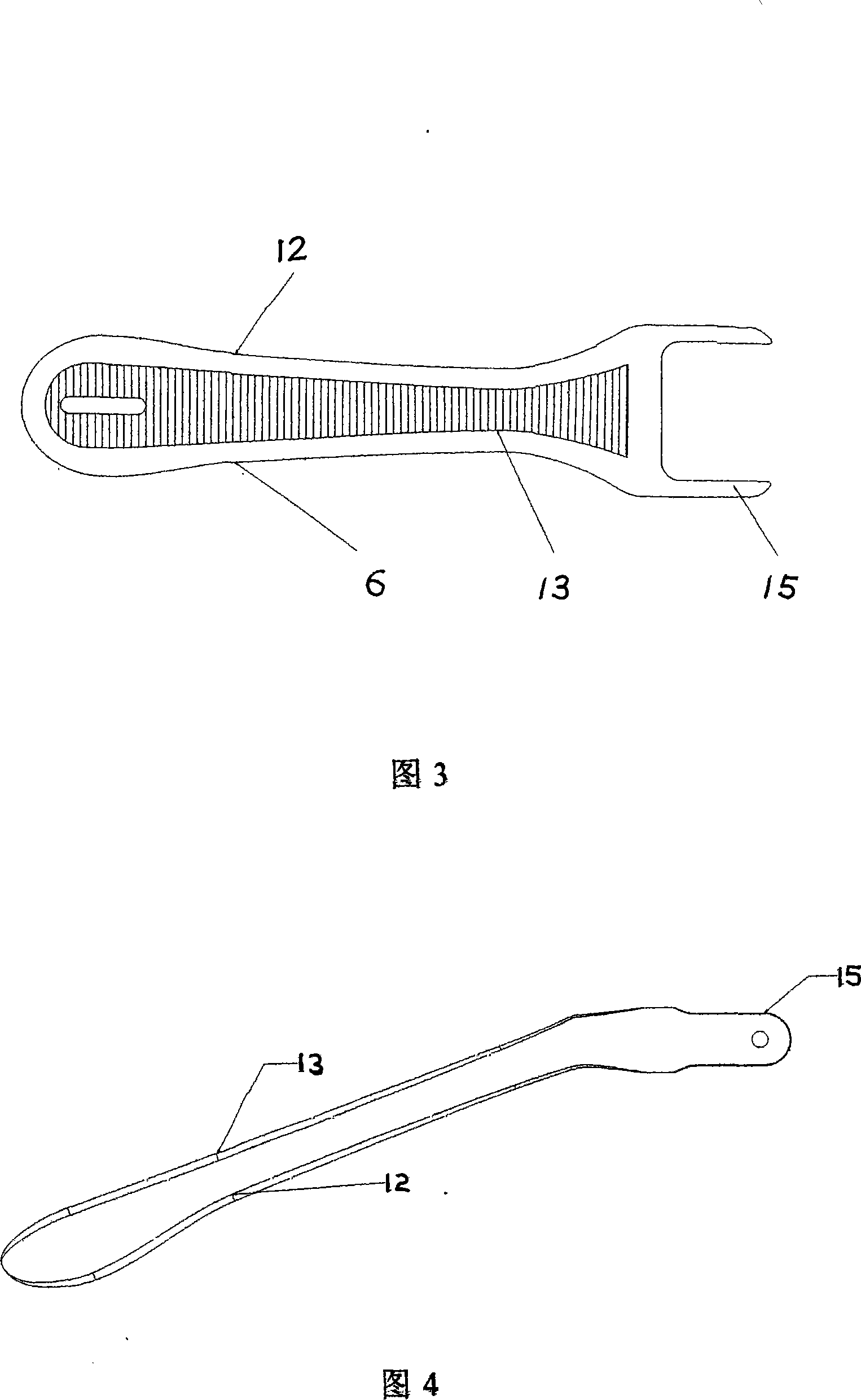

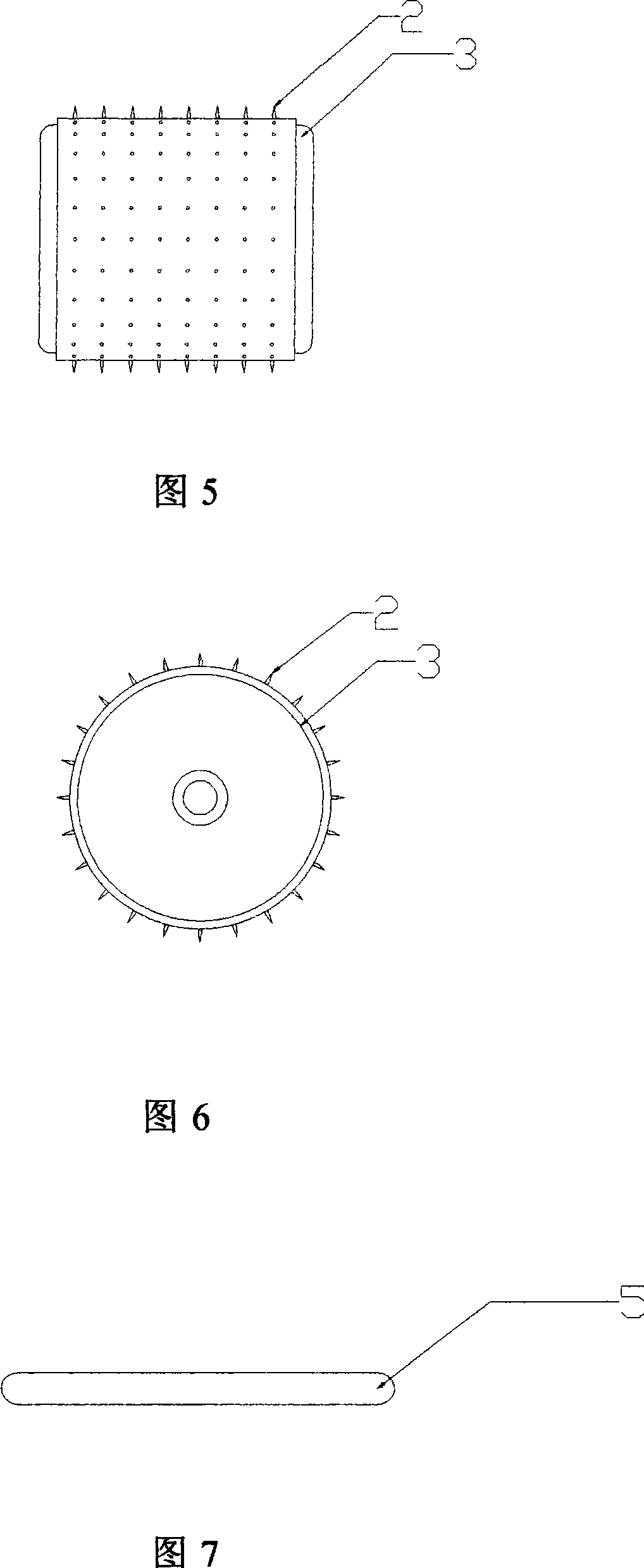

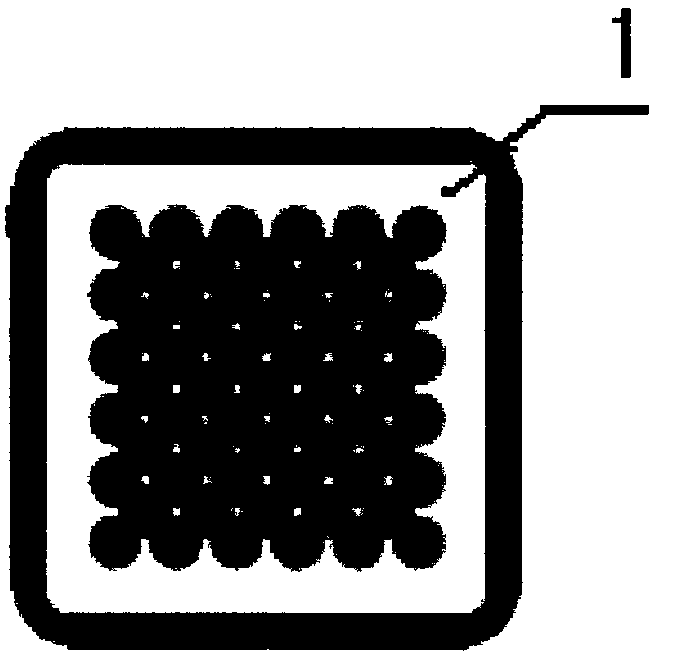

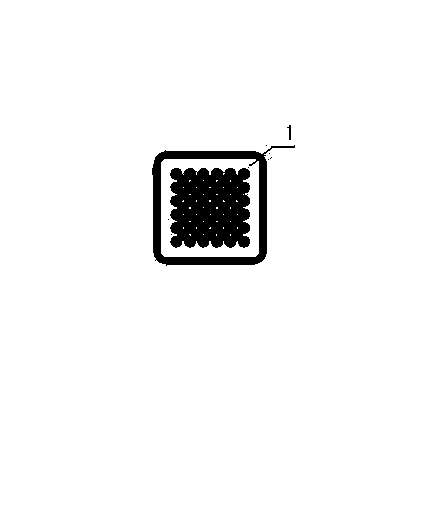

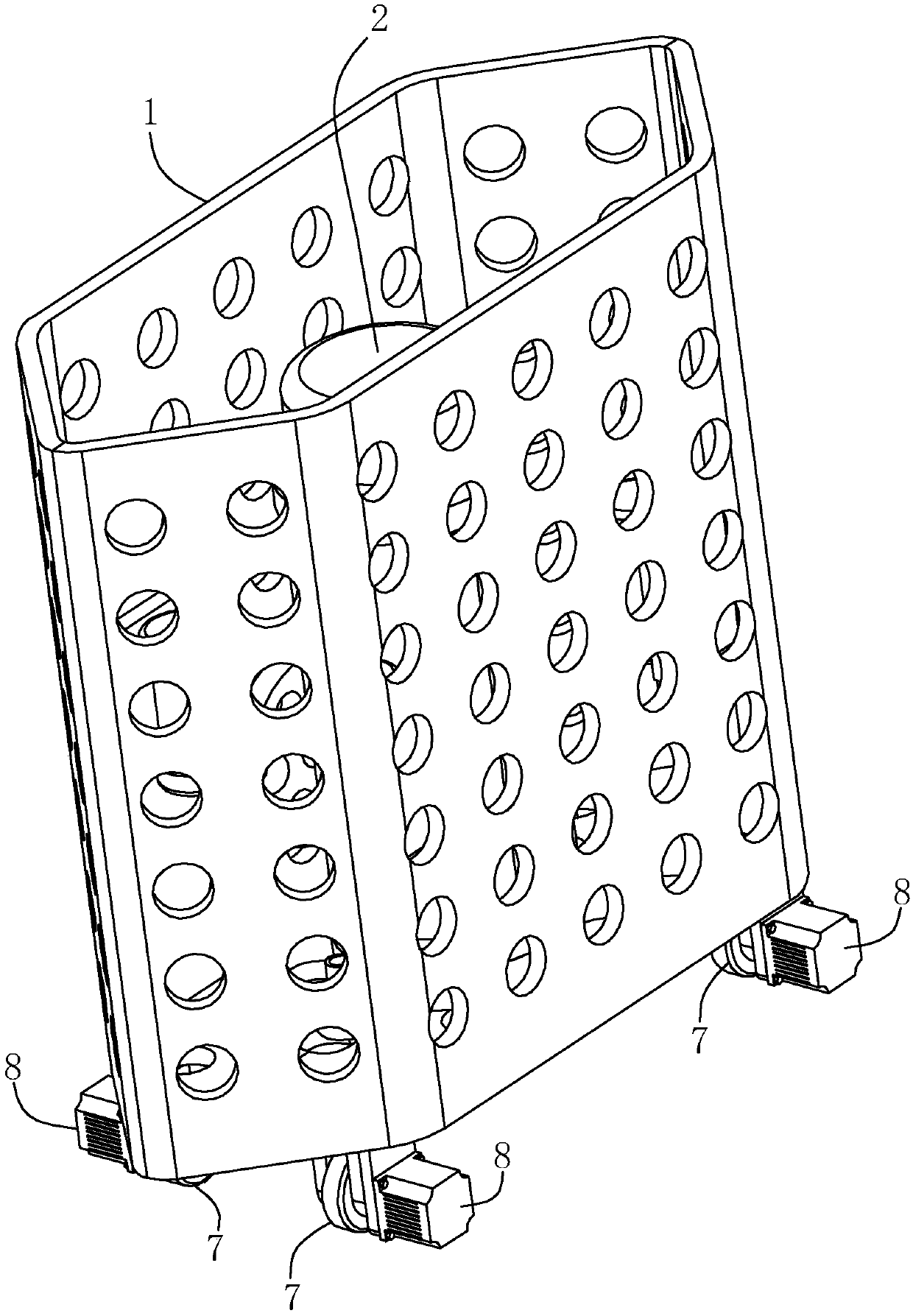

Manufacturing process flow of square microneedle massager

InactiveCN102166387AQuality improvementImprove practicalityMicroneedlesMedical devicesProtection KITIdler-wheel

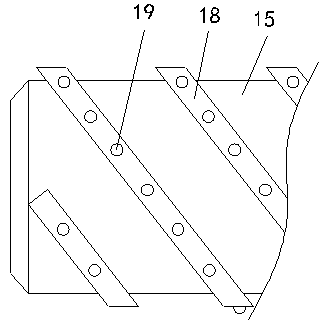

The invention relates to a manufacturing process flow of a square microneedle massager. The invention comprises the structure of a square microneedle massager and a manufacturing process flow of the square microneedle massager. The structure of the square microneedle massager comprises a plastic needle piece set, a square cover and a protective cover, wherein the plastic needle piece set is internally provided with a plastic needle piece and a hole shell, the plastic needle piece comprises rows of needle holes with the same intervals and rows of air vents with the same intervals, the rows of the needles holes are alternately arranged with the rows of the air vents, the hole shell is provided with rows of square holes with the same intervals, the square holes and the air vents on the plastic needle piece have the same intervals and are communicated with each other, the hole shell is embedded into the square cover, the back of the square cover is provided with a plurality of air vents, and the square cover is embedded into the protective cover. The square microneedle massager is smooth and regular in appearance, free of gaps, more healthful and convenient to use, and thorough in sterilizing and cleaning, so that the use time of the product is increased, and the aesthetic measure of a microneedle idler wheel is further improved.

Owner:沈忠忠

Edible oil storage tank breather valve capable of automatically cleaning filter membrane

ActiveCN110529639AAvoid easy cloggingReduce cloggingDispersed particle filtrationLarge containersEdible oilMechanical engineering

The invention provides an edible oil storage tank breather valve capable of automatically cleaning a filter membrane. The valve comprises a valve body, an exhalation valve disc and a rain shade are mounted at the top of the valve body; a center rod is fixedly connected to the bottom of the rain shade, a supporting ring is fixedly connected to the bottom of the exhalation valve disc, a filter membrane is laid on the supporting ring, a rotary disc is rotatably connected to the portion, located on the outer side of the center rod, in the exhalation valve disc, a rotary sleeve is installed on theouter side of the rotary disc, and scrapers distributed evenly are rotatably connected to the portion, located on the outer side of the rotary sleeve, in the exhalation valve disc. The filter membraneis arranged below the exhalation valve disc, so that small-particle impurities in the external environment are prevented from entering the edible oil storage tank; when the exhalation valve disc moves up and down to adjust the pressure, the scrapers in the exhalation valve disc extend out in a rotating mode to scrape and brush the filter membrane, impurities adhered to the filter membrane are automatically cleaned away, the possibility that the filter membrane is blocked is reduced, the safety of the breather valve is improved, and the cleaning effect of the multi-section scraper on the filter membrane is more thorough.

Owner:江苏复森特种阀门有限公司

Pressure cooker lid cleaning method and cleaning system

ActiveCN105105625AAvoid secondary pollutionReduce adverse effectsPressure-cookersMegasonic cleaningCleaning station

The invention discloses a pressure cooker lid cleaning method and cleaning system, and the system comprises a workpiece conveying device and a first ultrasound wave cleaning station, a second ultrasound wave cleaning station, a first rinsing station, a first spraying station, a film coating station, a second rinsing station, a second spraying station, a pure water cleaning station and a drying station which are arranged in sequence along the workpiece conveying device. The pressure cooker lid cleaning method and cleaning system provided by the invention has the advantages that the higher production efficiency is realized, the product quality is ensured and the labor cost is reduced.

Owner:HANGZHOU LIFUHAO MECHANICAL & ELECTRICAL EQUIP

Bridge cleaning machineshop truck and implementation method

ActiveCN110725249AAvoid secondary pollutionEasy to use for cleaning operationsRoad cleaningDust controlTruck

The invention relates to the field of bridge maintenance equipment, in particular to a bridge cleaning machineshop truck and an implementation method. The bridge cleaning machineshop truck comprises amachineshop truck body, a carriage, a first linear displacement mechanism, a second linear displacement mechanism, a third linear displacement mechanism, a telescopic seam cleaning mechanism, a dedusting mechanism, a positioning mechanism, a storage battery and a controller, wherein the carriage is fixedly connected with the machineshop truck body; the first linear displacement mechanism is fixedly mounted on the outer wall of the rear side of the carriage; the second linear displacement mechanism is fixedly mounted on the movable part of the first linear displacement mechanism; the third linear displacement mechanism is fixedly mounted on the movable part of the second linear displacement mechanism; the moving direction of the movable part of the third linear displacement mechanism is consistent with that of the movable part of the first linear displacement mechanism; and the telescopic seam cleaning mechanism is fixedly mounted on the movable part of the third linear displacement mechanism. According to the scheme, multiple impurities in a bridge telescopic seam are automatically cleaned to save the human cost, the cleaning effect is thorough, the working efficiency is high, thecruising ability is high, and the safety is high.

Owner:郭云美

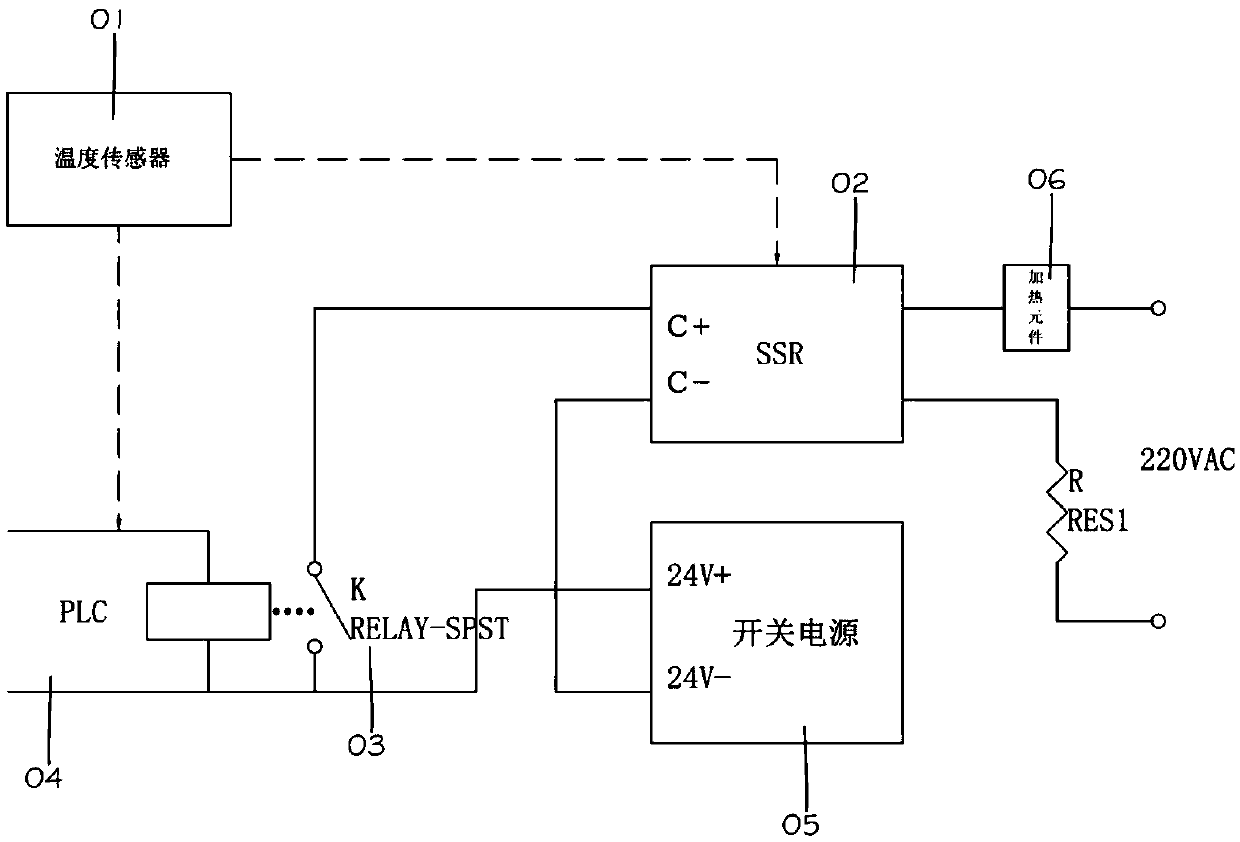

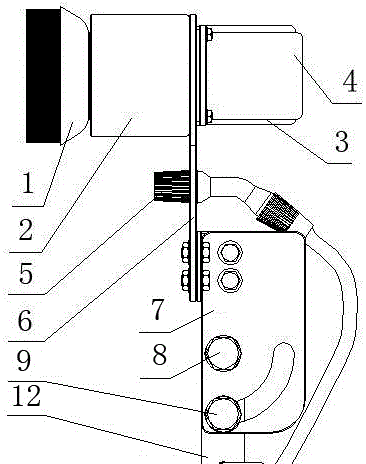

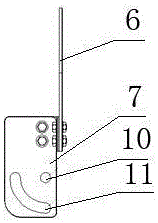

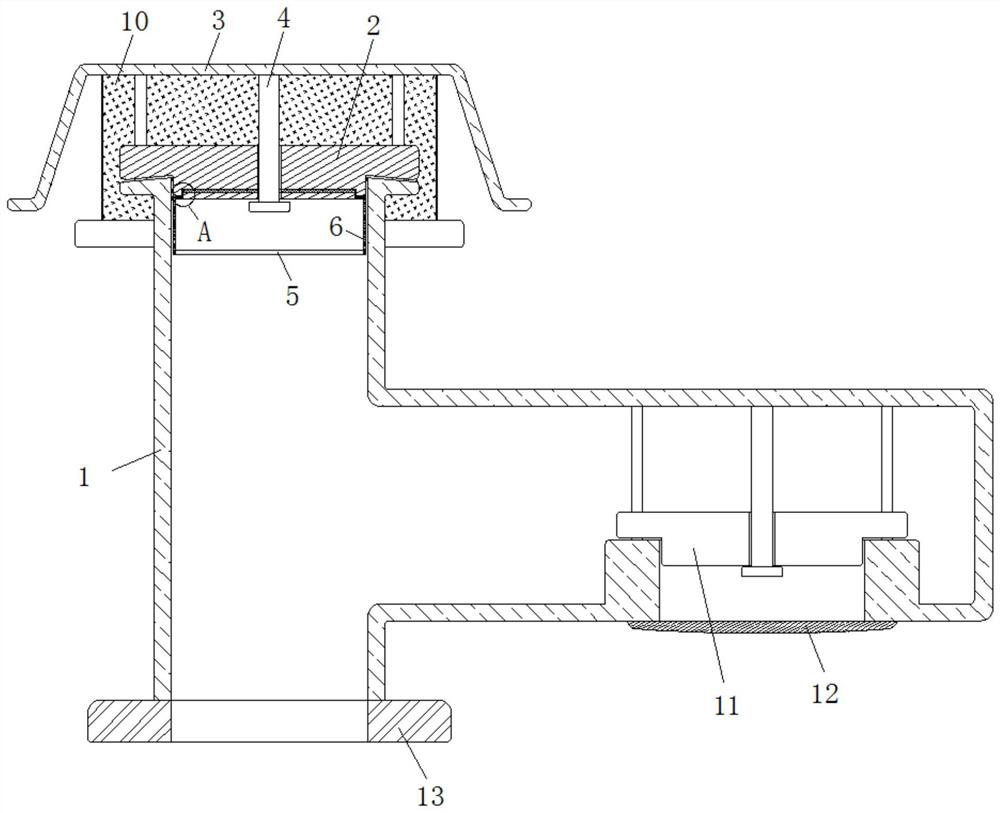

Coating machine heating control method and coating machine

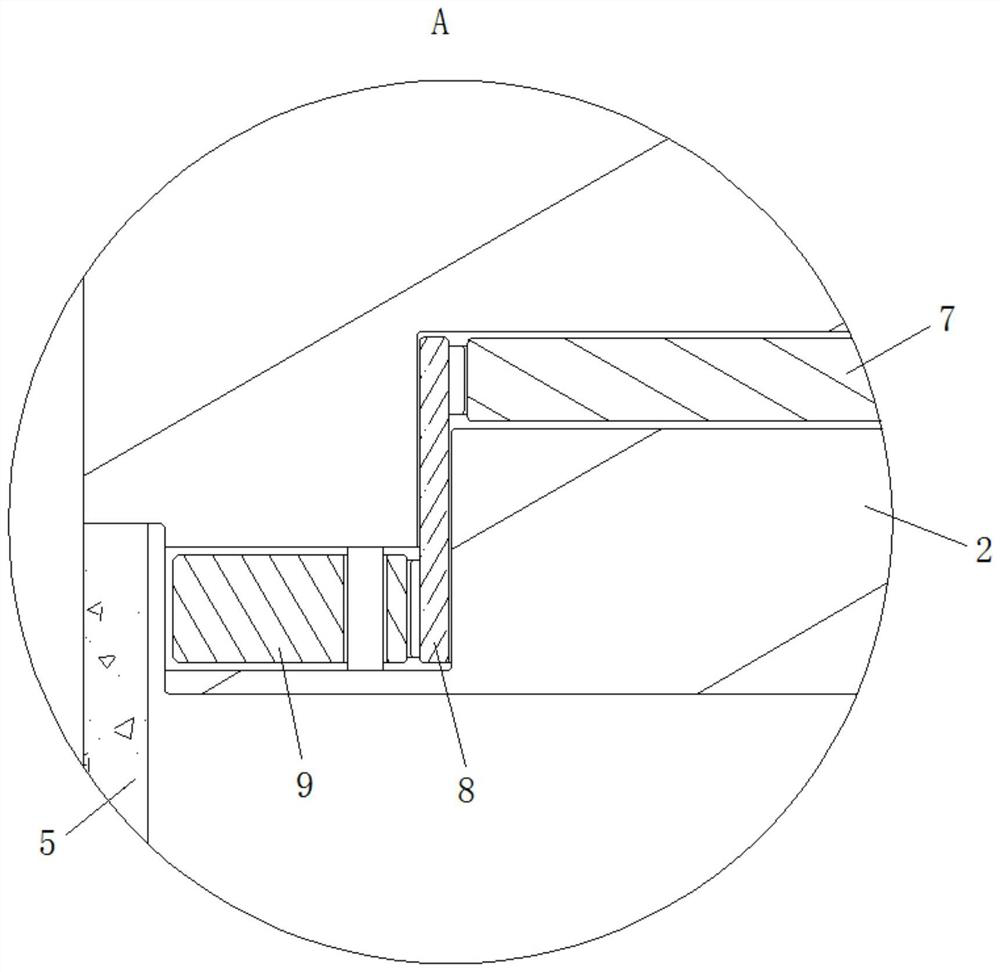

InactiveCN108670856AThorough cleaning effectEasy to install and removePharmaceutical product form changeDomestic articlesAgricultural engineeringProgrammable logic controller

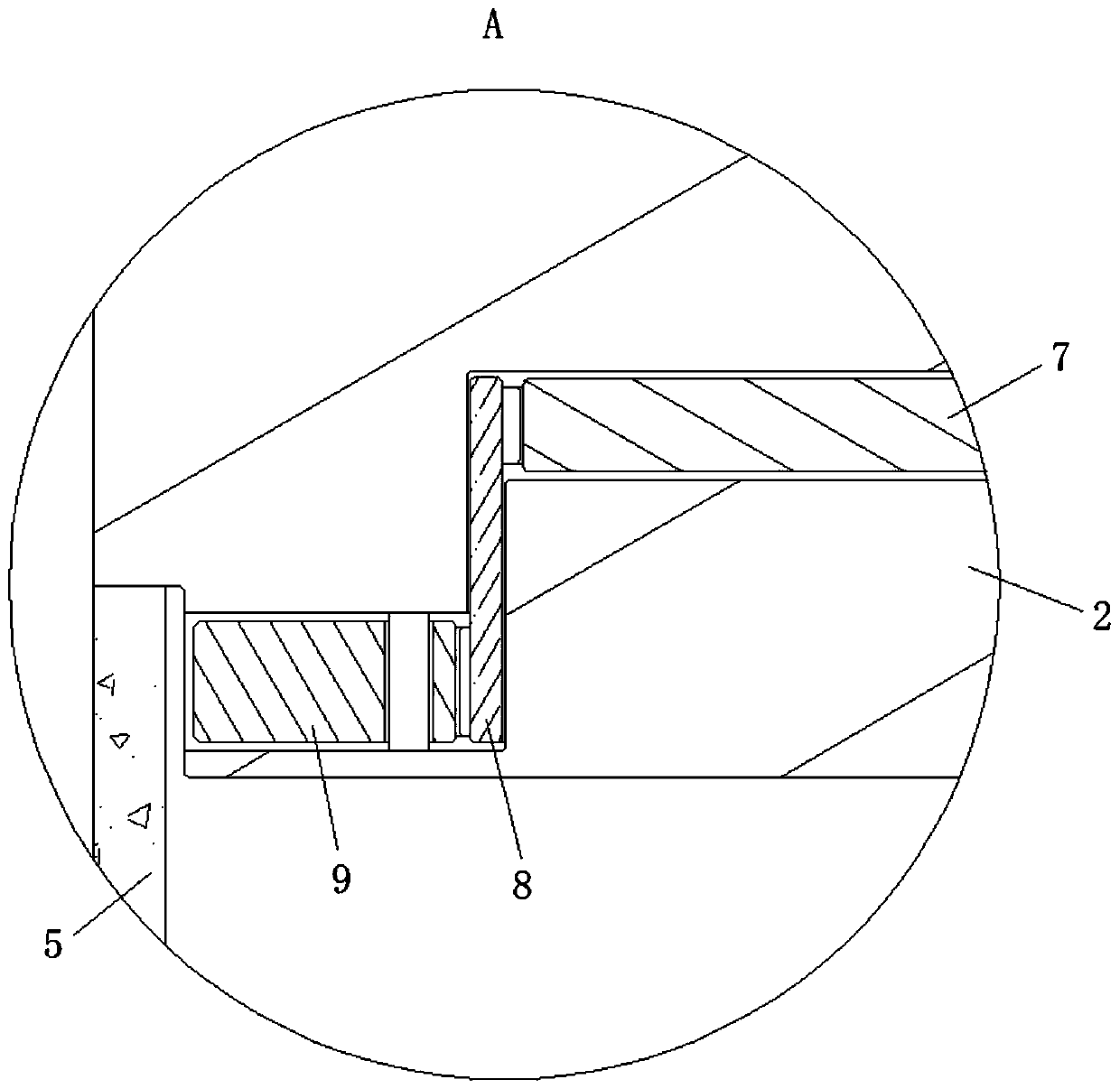

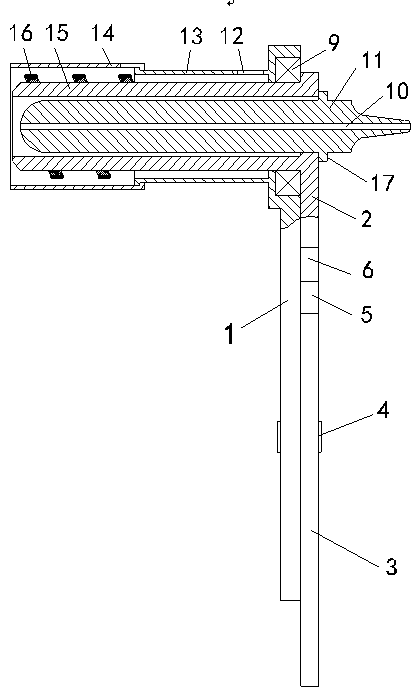

The invention discloses a coating machine heating control method which comprises a temperature sensor, a solid relay, a single-pole single throw relay, a PLC (programmable logic controller), a switchpower supply and a heating element, wherein an on-off frequency of the solid relay is calculated through a PID (proportion integration differentiation) algorithm, and thus an effect of controlling a heating temperature can be achieved. Real-time precise control on a coating machine temperature system is achieved. The invention further discloses a coating machine which comprises an air inlet machine, a controller, a coating machine and an exhaust machine, wherein the coating machine comprises an upper tank and a lower tank; an annular mounting rack is mounted on the inner wall of the upper tank; an annular cleaning tube is arranged on the annular mounting rack. Due to adoption of the annular cleaning tube, all-closed all-direction cleaning can be achieved, a thorough cleaning effect can beachieved, different cleaning tubes can be conveniently replaced, the coating machine is convenient to mount and dismount, meanwhile, the annular cleaning tubes can be conveniently cleaned, and cross pollution can be avoided. In addition, a through hole is formed in the annular cleaning tube, the operation of a spray gun component is not interfered, and the coating machine is reasonable in structural design and good in practicability.

Owner:JIANGXI YIKANG MACHINERY TECH CO LTD

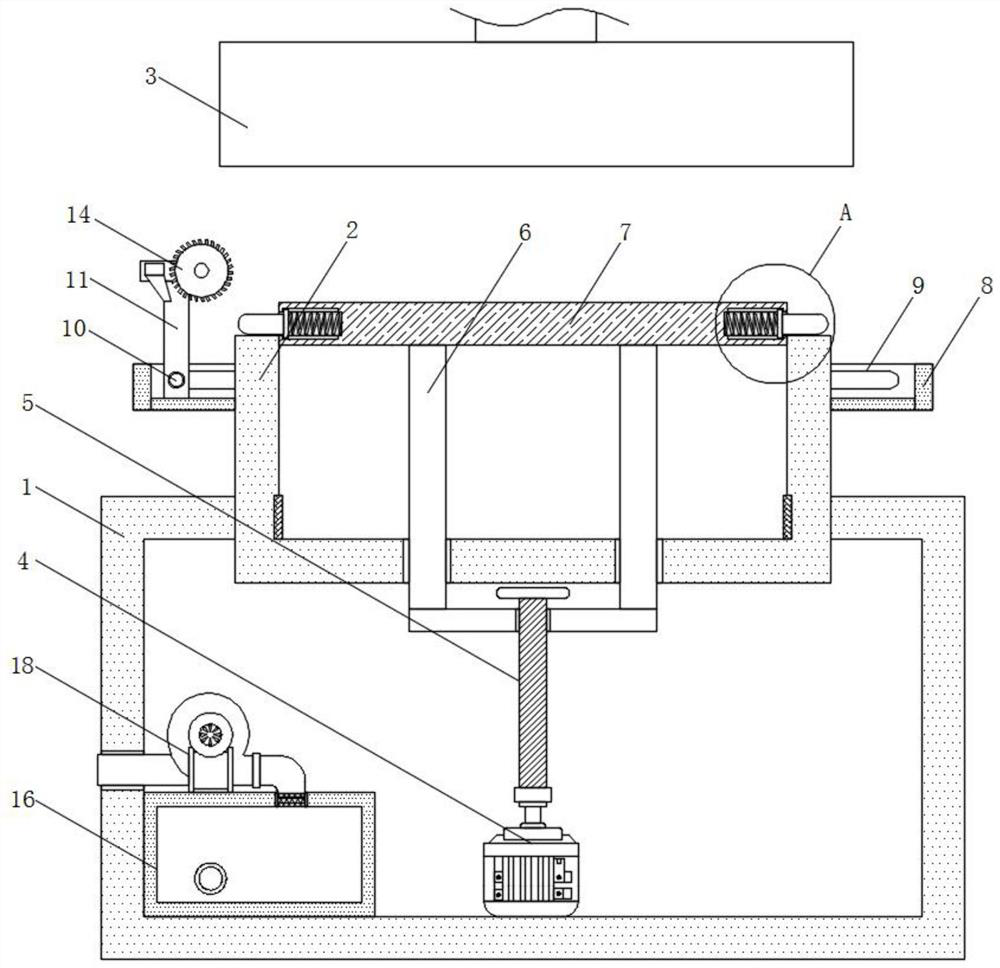

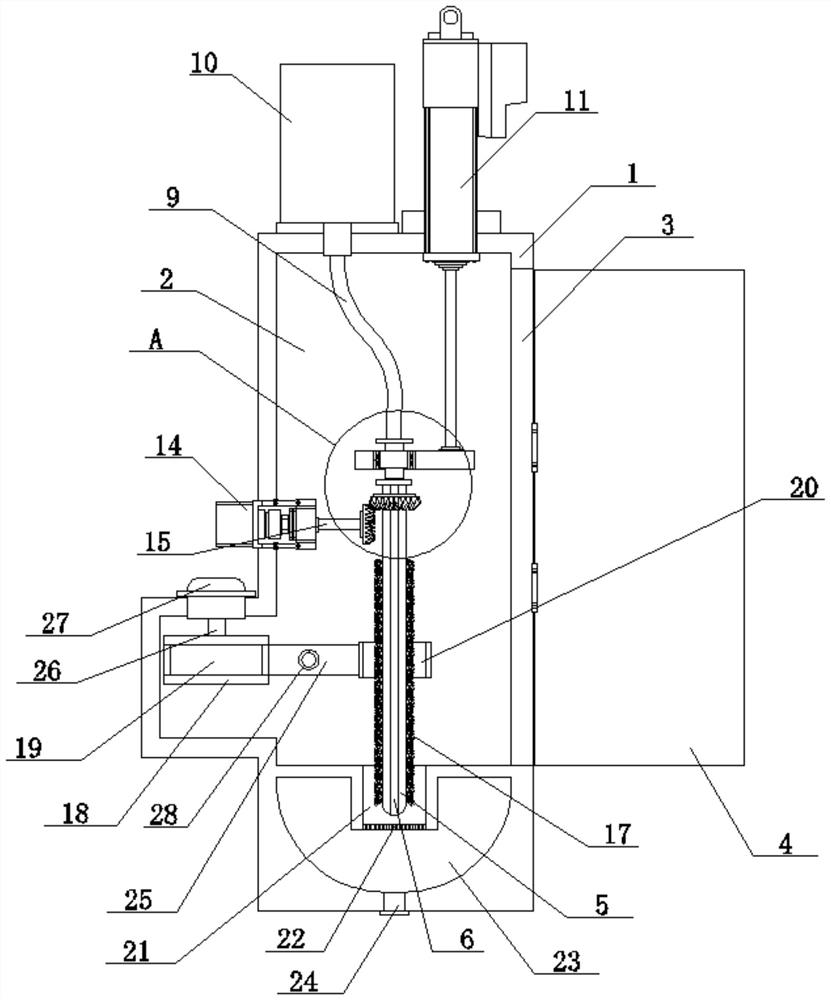

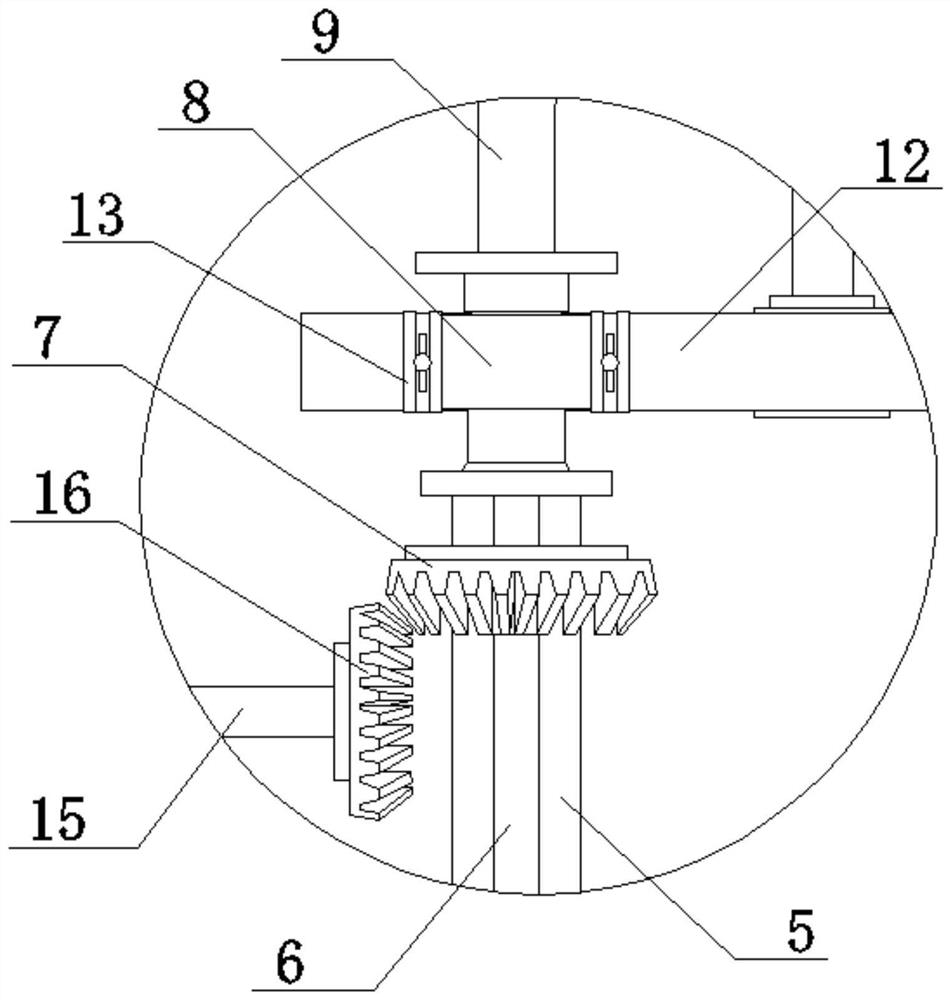

Injection mold with mold cavity cleaning structure

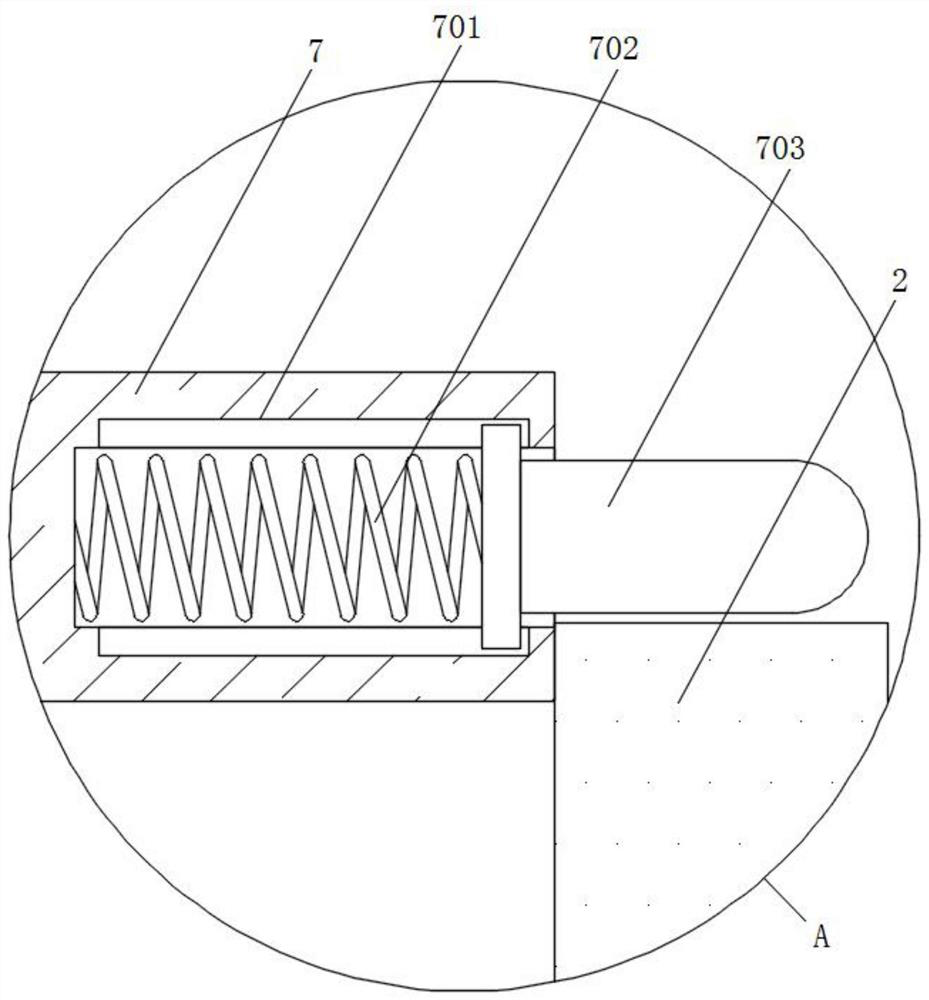

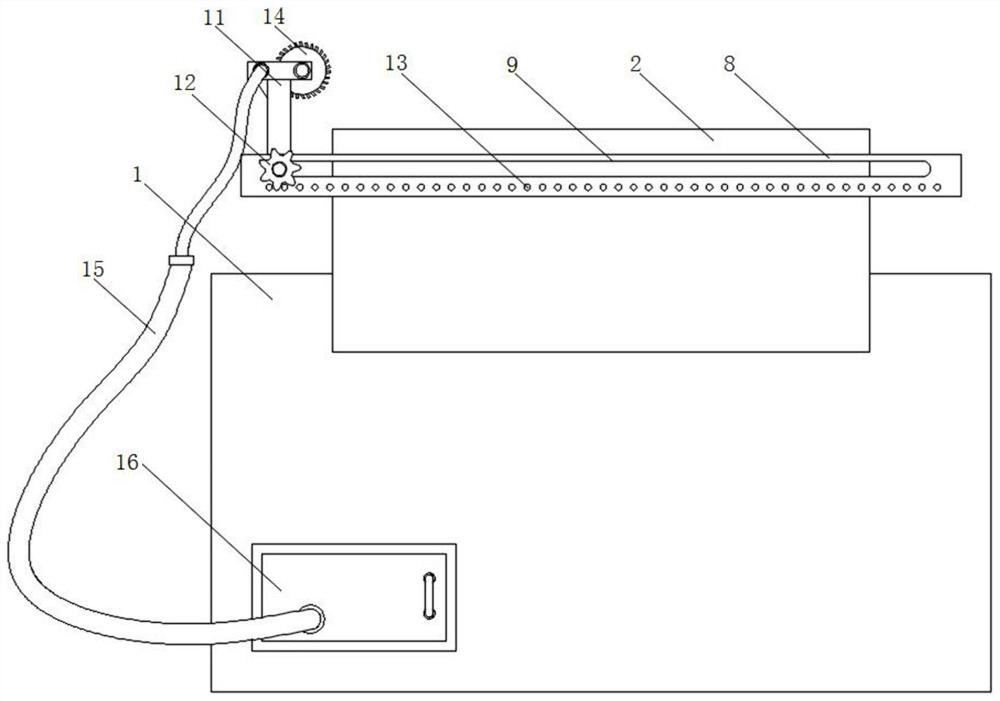

PendingCN112123644AEasy to cleanThorough cleaning effectDispersed particle filtrationElectric machineGear wheel

The invention discloses an injection mold with a mold cavity cleaning structure, and belongs to the technical field of injection molds. The injection mold comprises a base, wherein the top of the baseis fixedly connected with a lower mold; the bottom of the lower mold penetrates through and extends into the base; an upper mold is arranged above the lower mold; the inner bottom wall of the base isfixedly connected with a first motor; the top of the first motor is fixedly connected with a screw rod through a coupler; and the outer part of the screw rod is in threaded connection with a liftingframe. According to the injection mold, impurities on the inner wall of the lower mold can be scraped off in the ascending process of a scraping plate, a second motor can drive a connecting shaft to rotate, so that a gear fixed outside the second motor can rotate; and the gear is meshed with a convex block, so that the gear can move rightwards, the connecting shaft moves rightwards, cleaning frames can be driven to move rightwards, the tops of the two cleaning frames are fixedly connected with a cleaning assembly, the cleaning assembly can move rightwards to clean the scraping plate, and therefore the cleaning effect is more thorough.

Owner:苏州福满堂电器科技有限公司

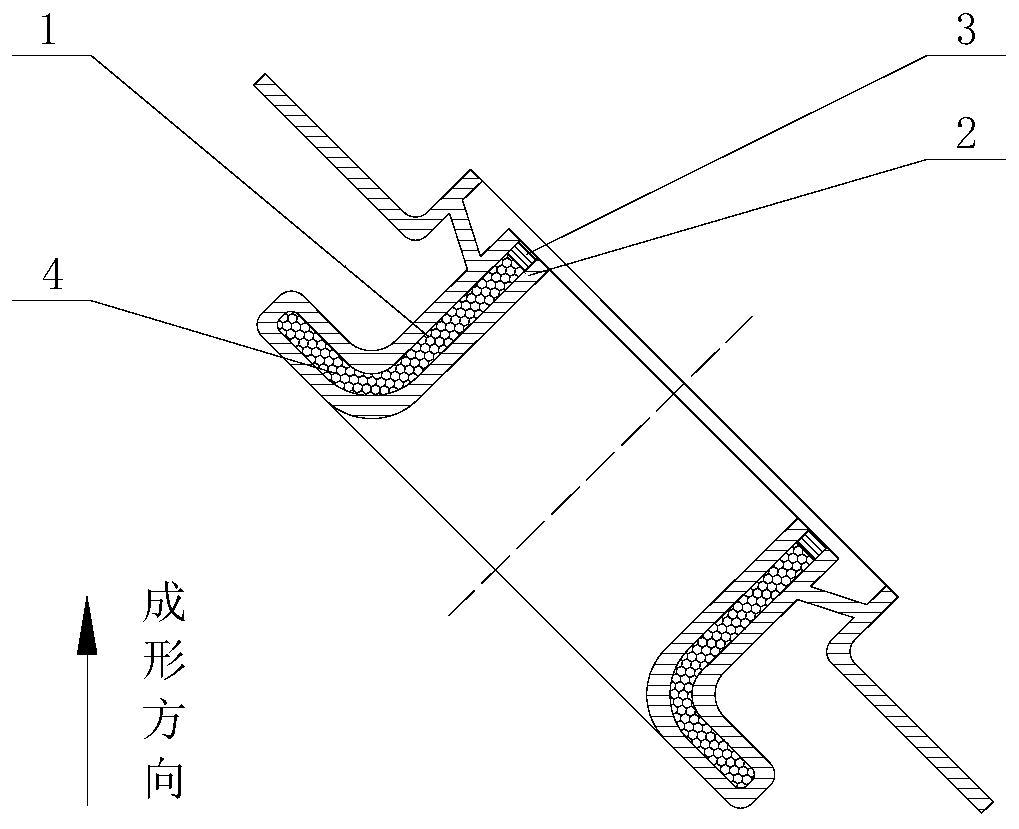

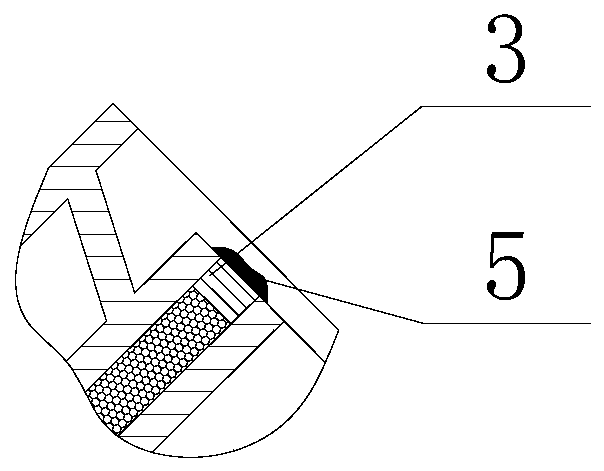

Manufacturing method for micro holes of additive manufacturing part

ActiveCN110153426APrevent outflowGood removal effectAdditive manufacturing apparatusIncreasing energy efficiencyFilling materialsAdditive layer manufacturing

The invention discloses a manufacturing method for micro holes of an additive manufacturing part. The manufacturing method comprises the following steps: step I, sealing an outlet end of a cavity structure with support while forming a part with the cavity structure through laser selective melting and additive manufacturing, and enabling the outlet end of the cavity structure to face towards a forming direction, thereby obtaining the part with the cavity structure; step II, drying the obtained part; step III, completely sealing the outlet end of the dried part with a sealing material; step IV,performing micro hole processing on the completely sealed part; step V, removing the sealing material and the support after micro hole processing is accomplished; and step VI, clearing powder in the cavity structure. The laser selective melting and additive manufacturing technical feature is adopted to take powder in a forming process as a cavity protective material to perform micro hole processing, so that a follow-up special material filling process is saved, and powder in the cavity is filled more compact, and therefore, damages and pollution on the inner wall of the cavity in a micro holeprocessing process can be affectively avoided.

Owner:AECC AVIATION POWER CO LTD

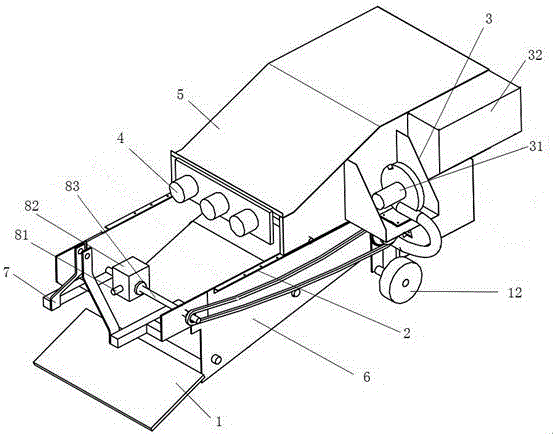

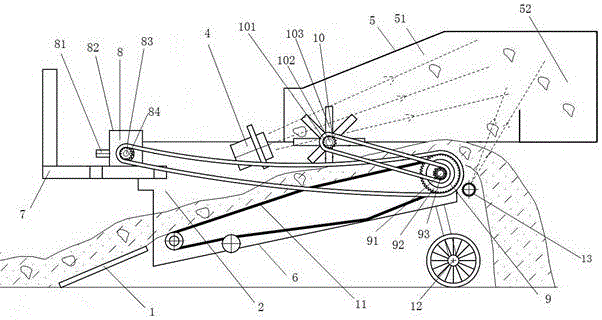

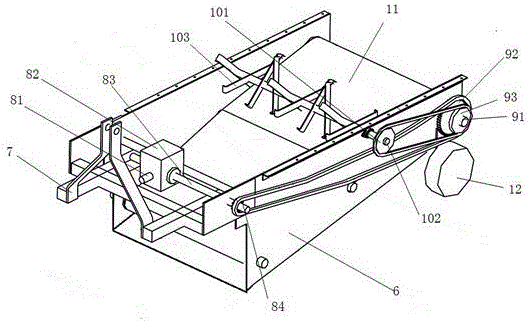

Plastic film residue pickup machine

ActiveCN106171067AReduce pollutionMaintain sustainable developmentRenewable energy machinesGatherer machinesPlastic filmWind power generation

The invention discloses a plastic film residue pickup machine. The plastic film residue pickup machine comprises a soil shoveling plate, a pickup vehicle body, a wind power generation device, first air outlet devices and a plastic film residue collection box, wherein an inlet is formed in the front end of the pickup vehicle body, an outlet is formed in the rear end, the soil shoveling plate is obliquely arranged in front of the pickup vehicle body, the high end of the soil shoveling plate is connected with the inlet of the pickup vehicle body, a soil conveying part and a stirring part are arranged in the pickup vehicle body, the soil conveying part is arranged in the direction from the inlet to the outlet, the stirring part is arranged above the soil conveying part, the plastic film residue collection box is arranged at the top of the pickup vehicle body, the first air outlet devices are arranged in front of the stirring part and connected with the wind power generation device through air pipes, air flows out of the first air outlet devices in the direction blowing from the stirring part to the plastic film residue collection box, and air inlets are formed in corresponding positions of the plastic film residue collection box. The problems that a conventional plastic film residue recovery machine cannot clean and recover plastic film residues in deep soil, cleans and recovers the plastic film residues in shallow soil incompletely and requires manual secondary cleaning are solved.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

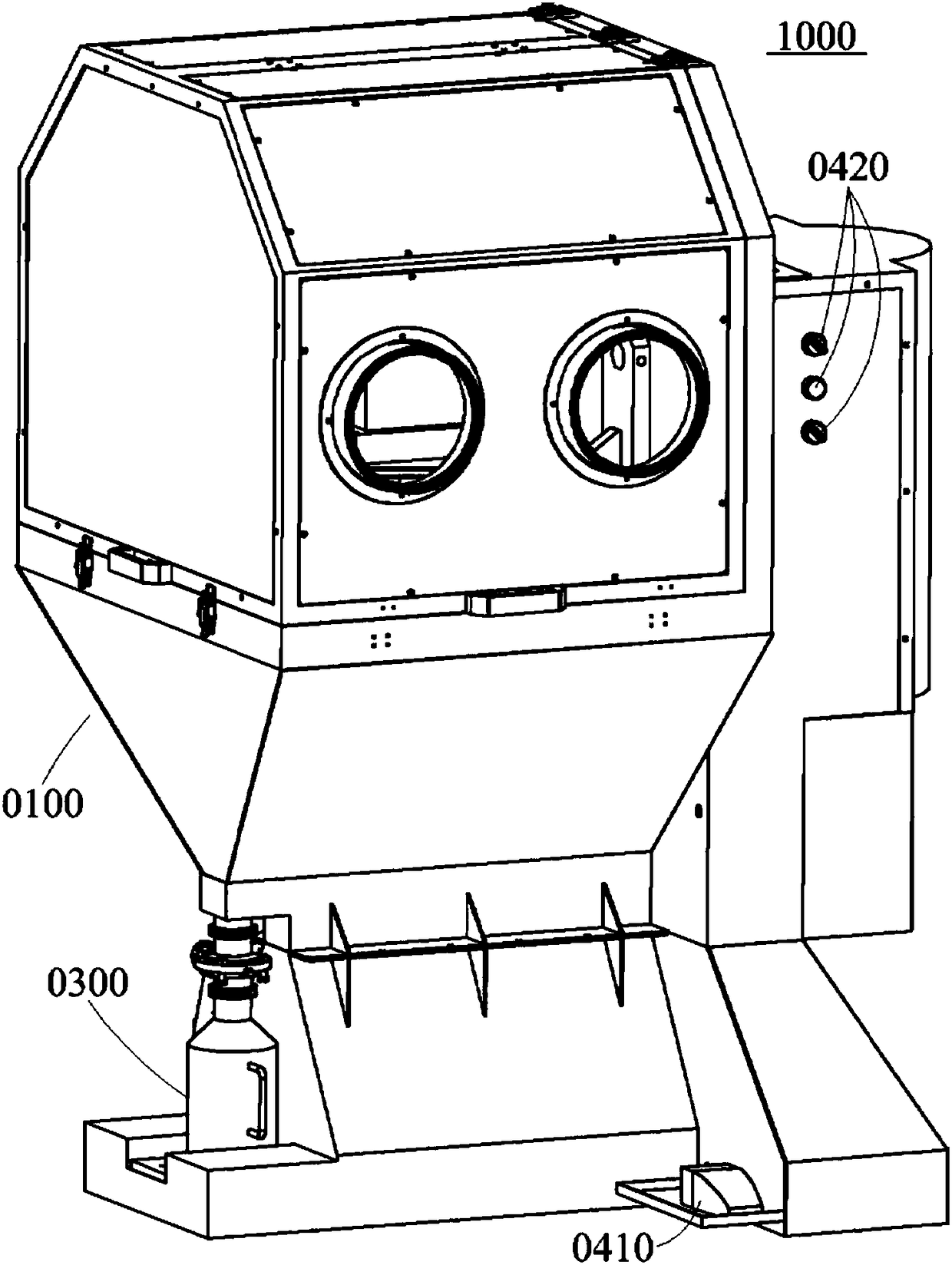

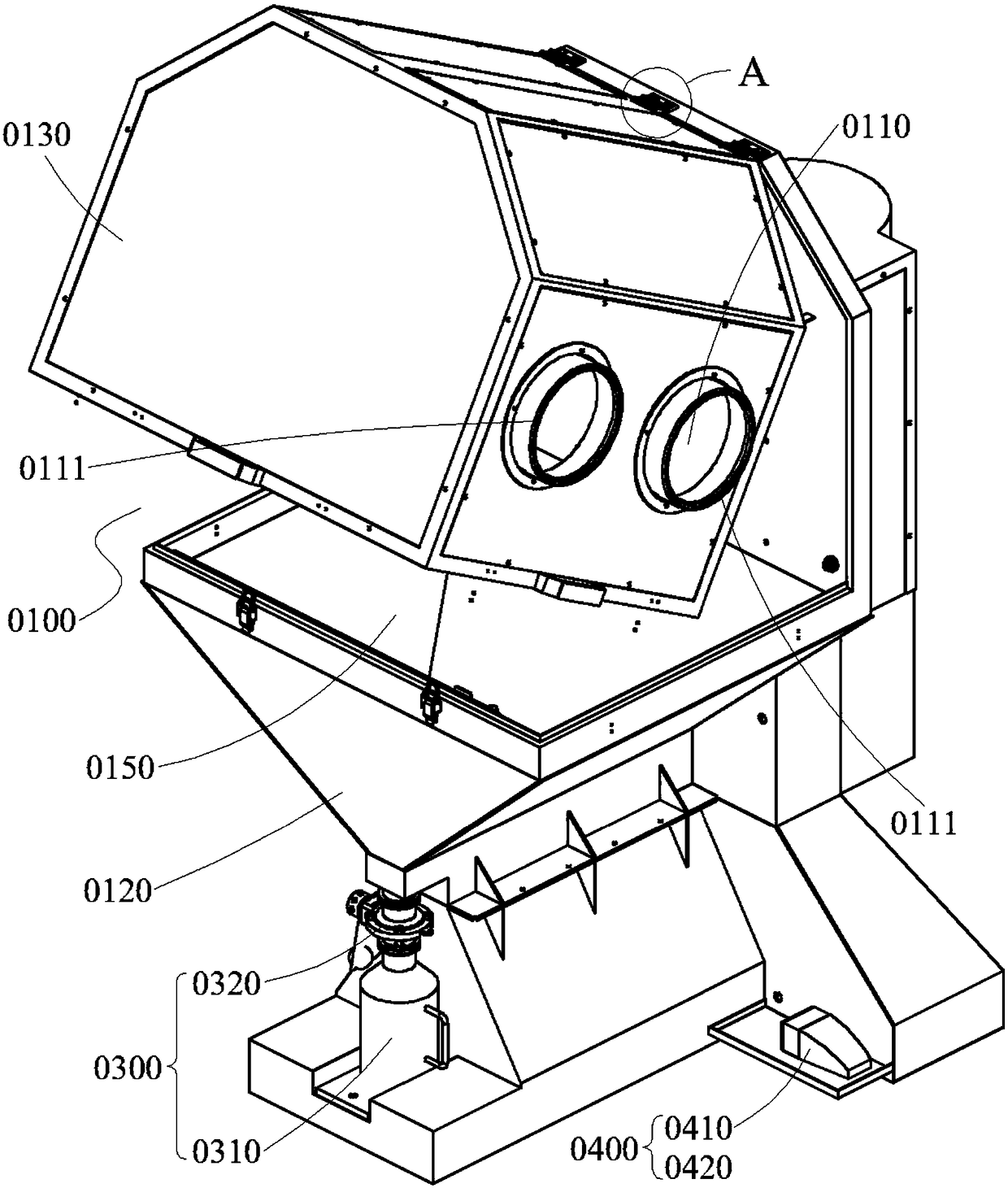

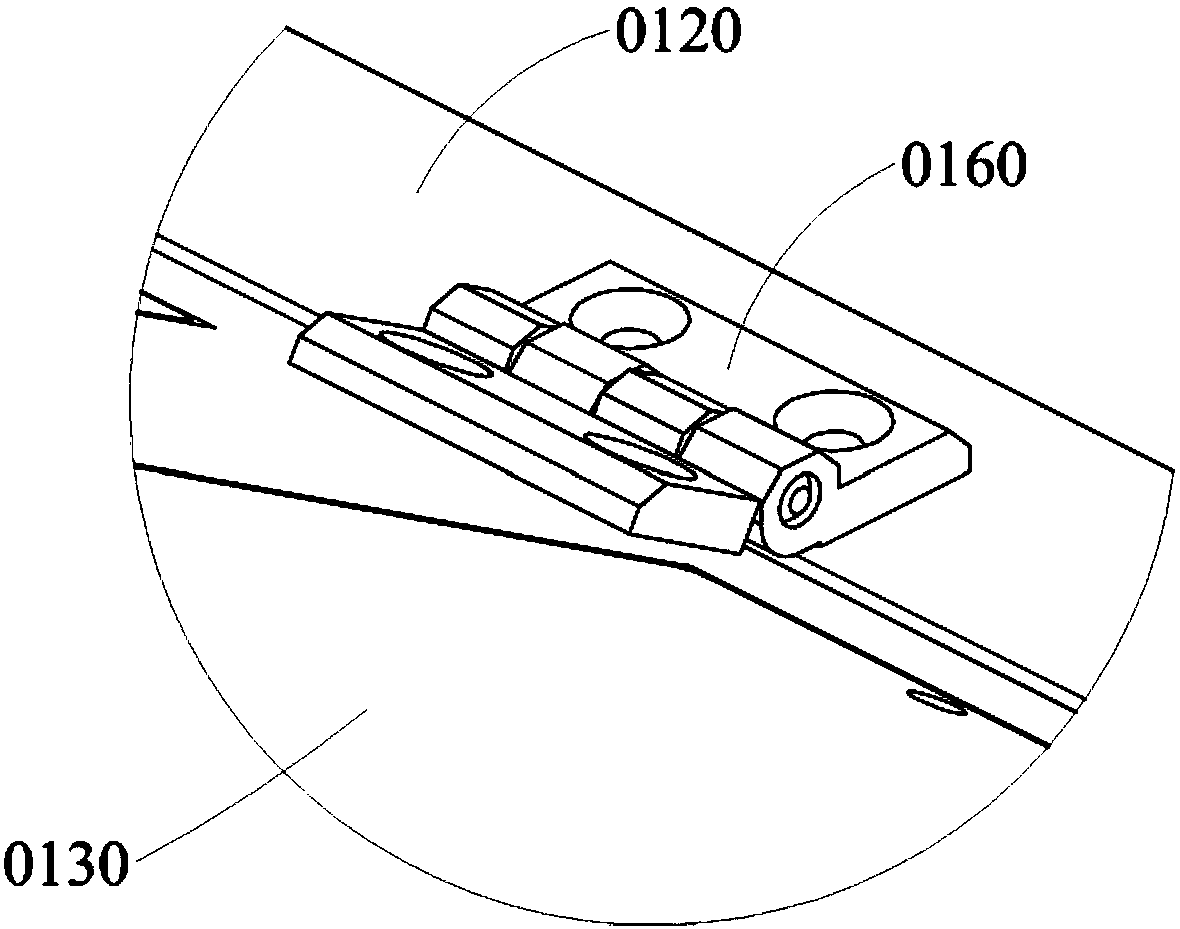

Workpiece automatic clearing device

PendingCN108582770AAchieve cleanupImprove cleaning efficiencyAdditive manufacturing apparatusManufacturing recyclingEngineeringMechanical engineering

The invention discloses a workpiece automatic clearing device. The workpiece automatic clearing device comprises a dust-free operation cavity, a blowing device and a collecting device; the dust-free operation cavity is provided with operation glove openings used for installing an operation glove; the blowing device is arranged in the dust-free operation cavity, and comprises a clamping unit and ablowing unit, wherein the clamping unit is used for clamping a workpiece, and the blowing unit is used for blowing the workpiece, and at least two directions of relative rotation degrees are arrangedbetween the clamping unit and the air blowing unit; and the collecting device is used for collecting powder materials in the dust-free operation cavity. According to the workpiece automatic clearing device, automatic powder clearing can be achieved in an inert gas environment, meanwhile, the multi-direction automatic cleaning capability is achieved, so that the cleaning efficiency and the safety are effectively improved.

Owner:苏州倍丰智能科技有限公司

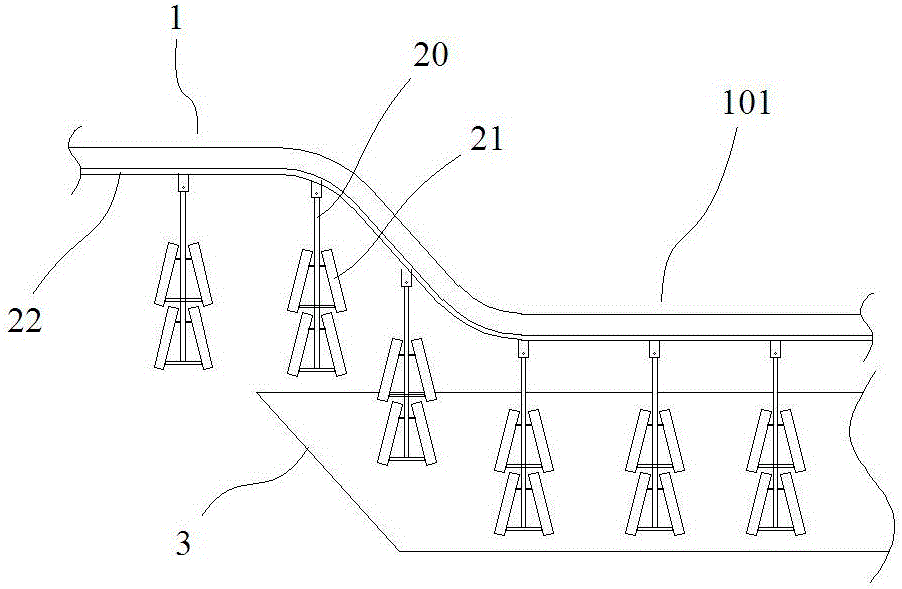

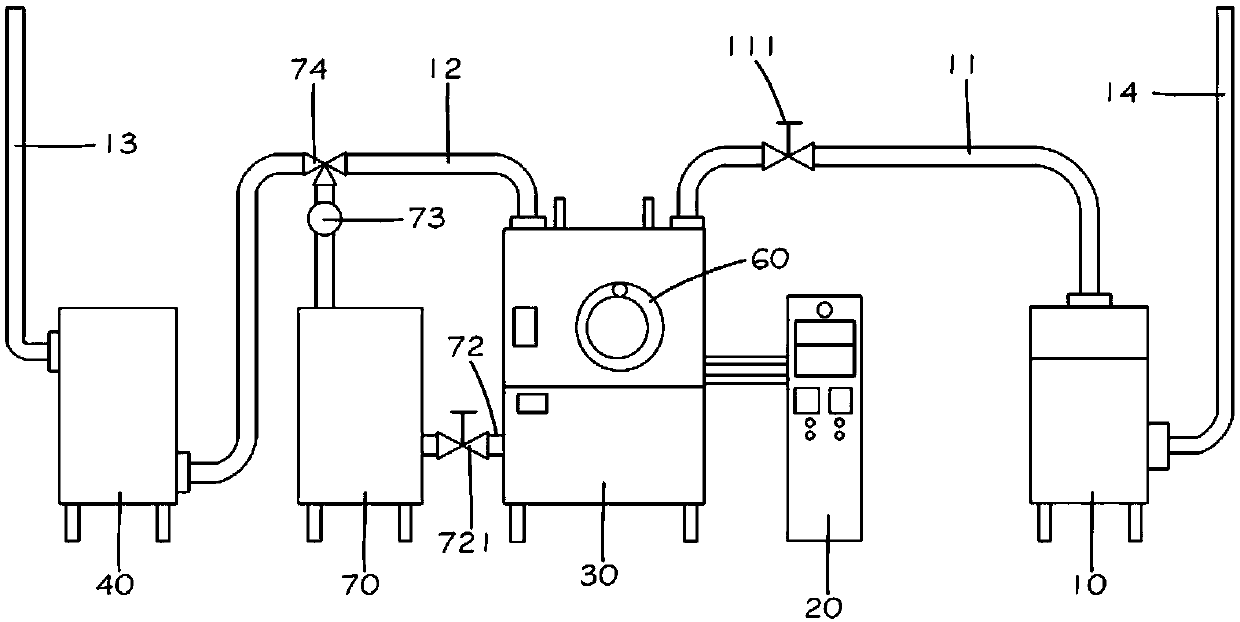

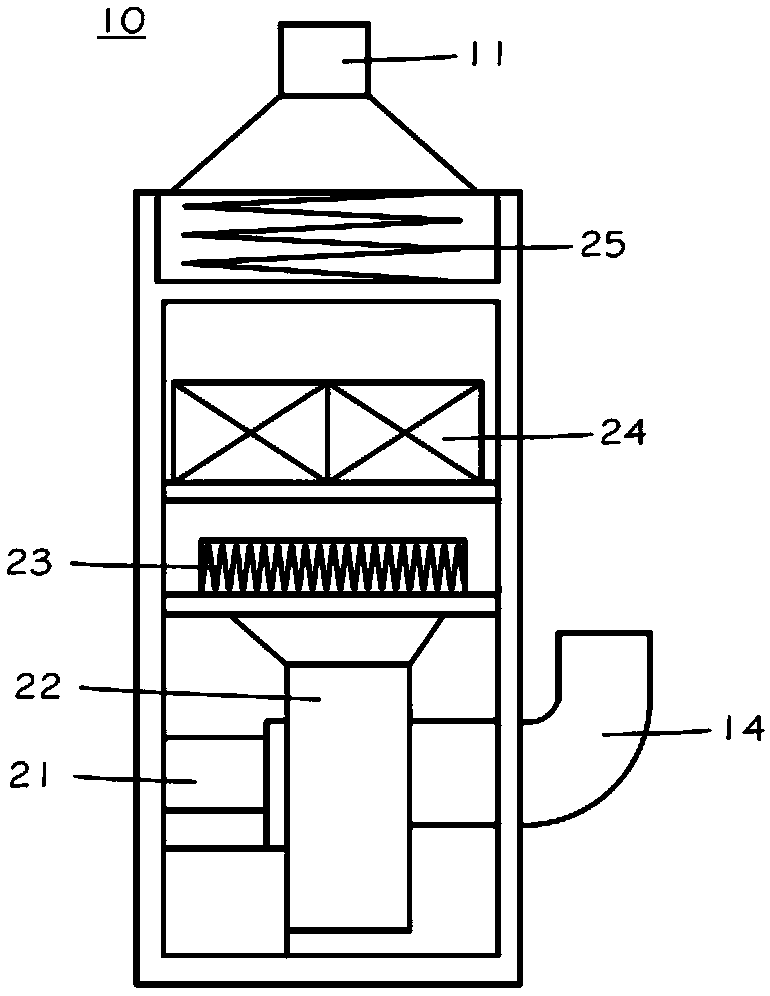

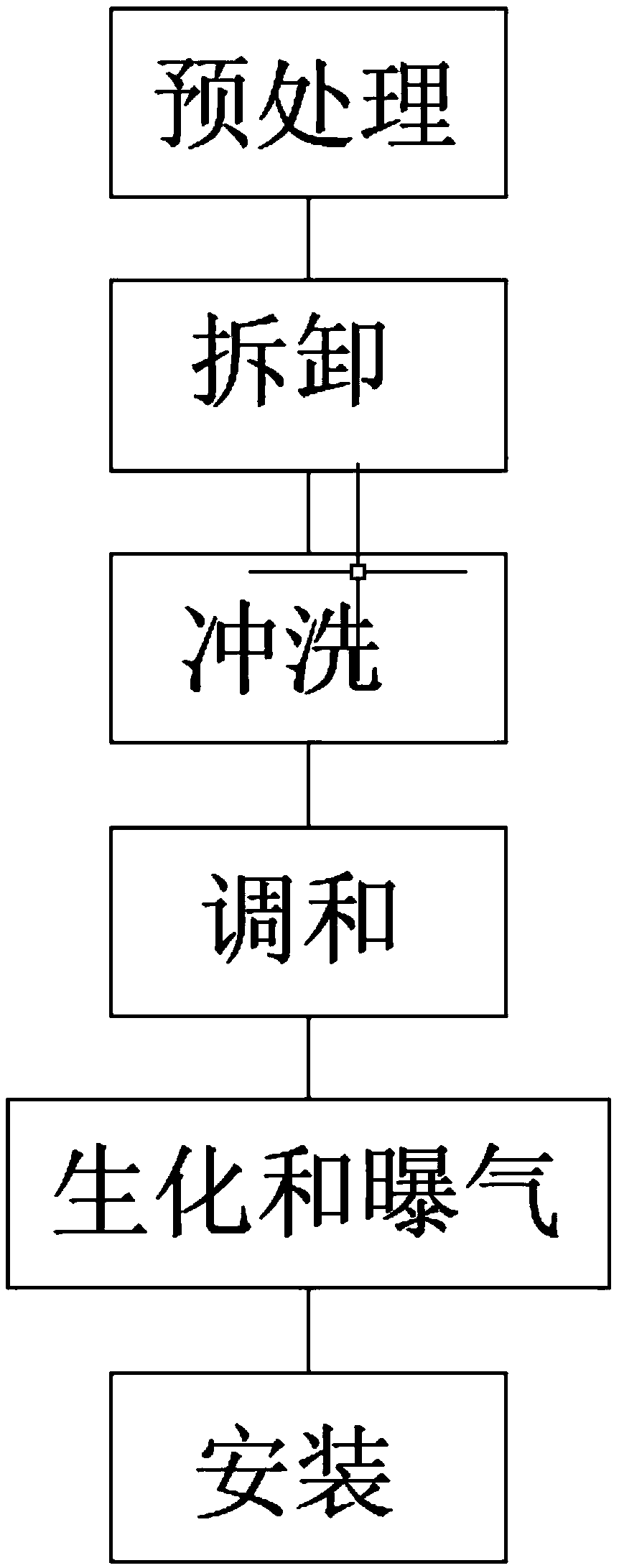

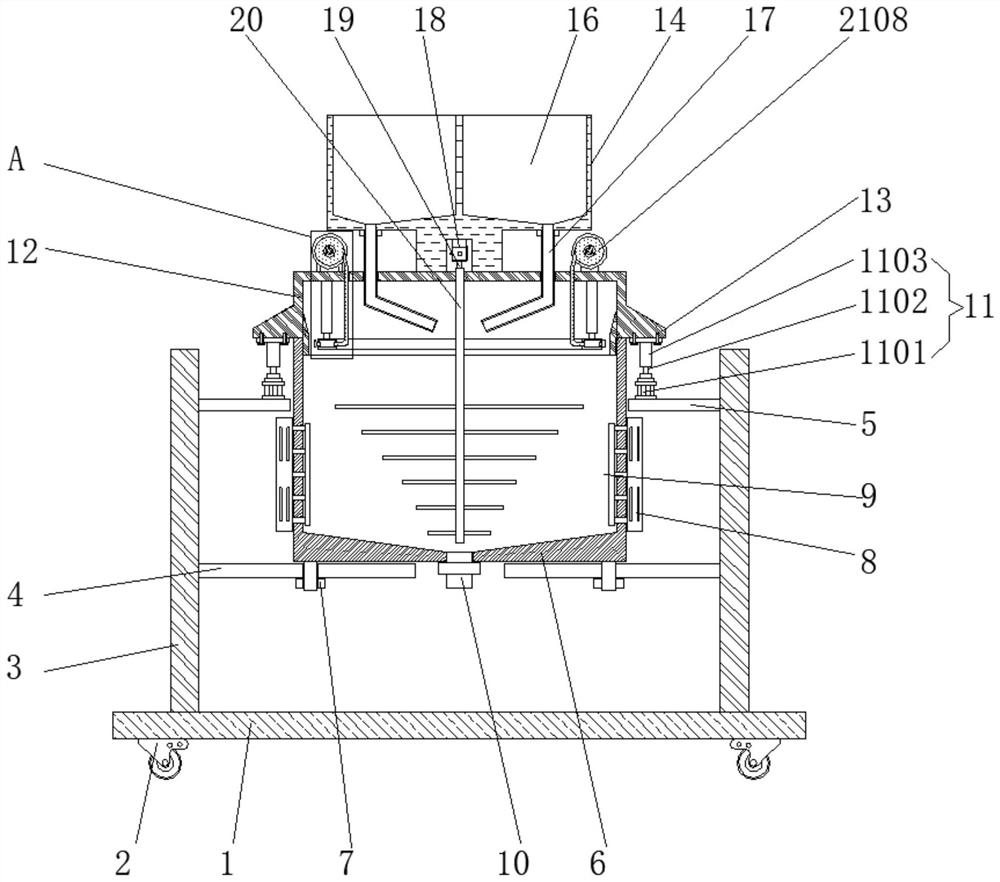

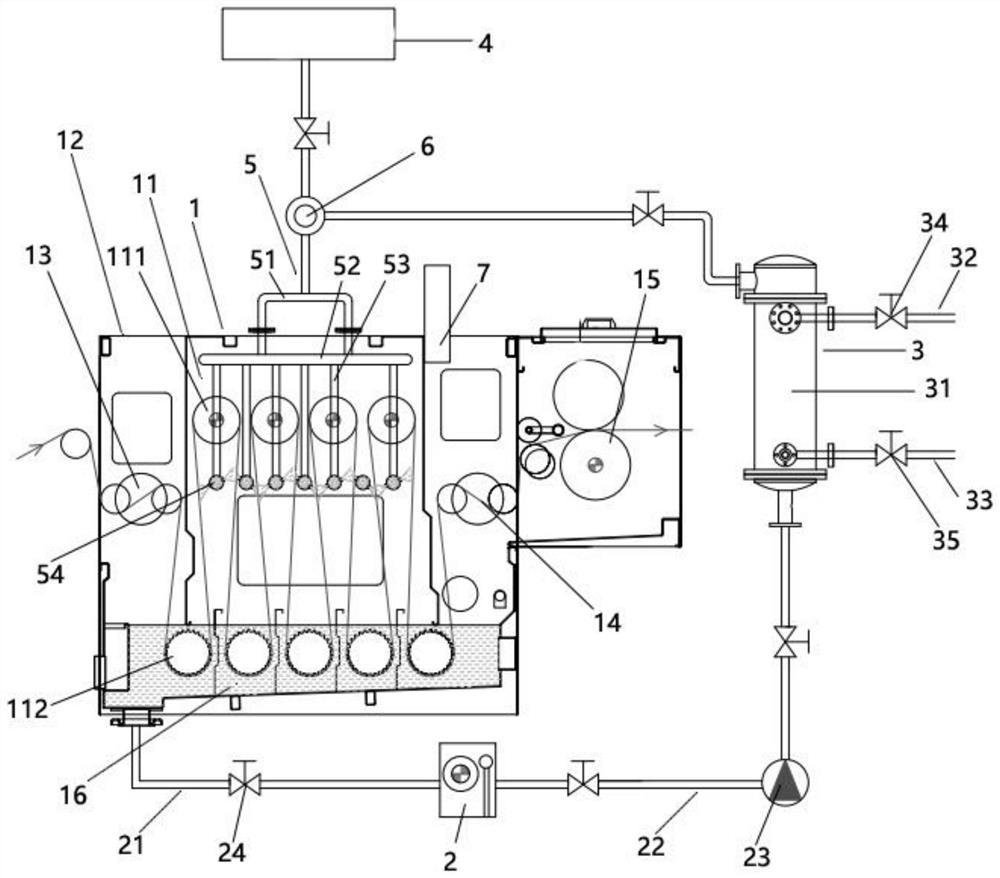

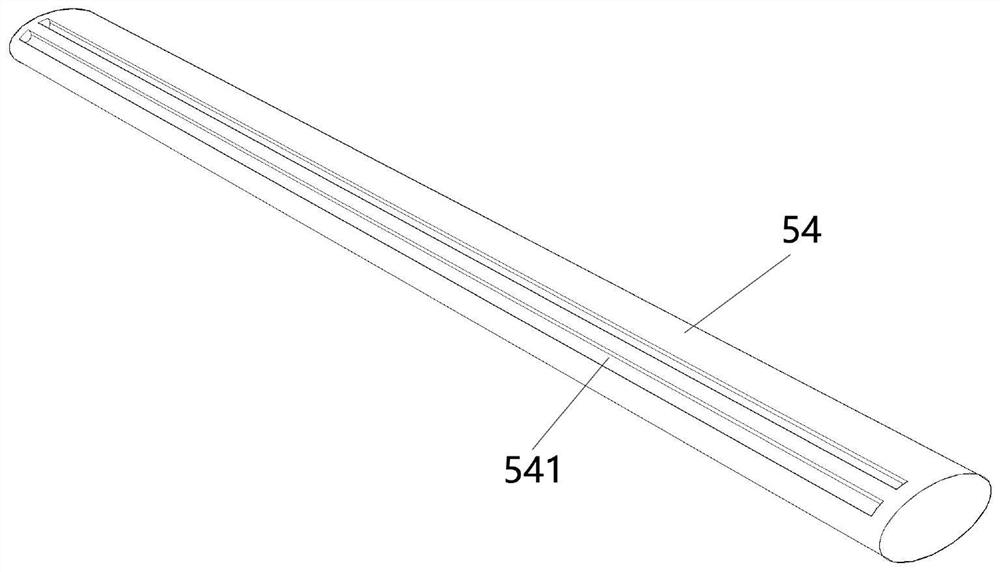

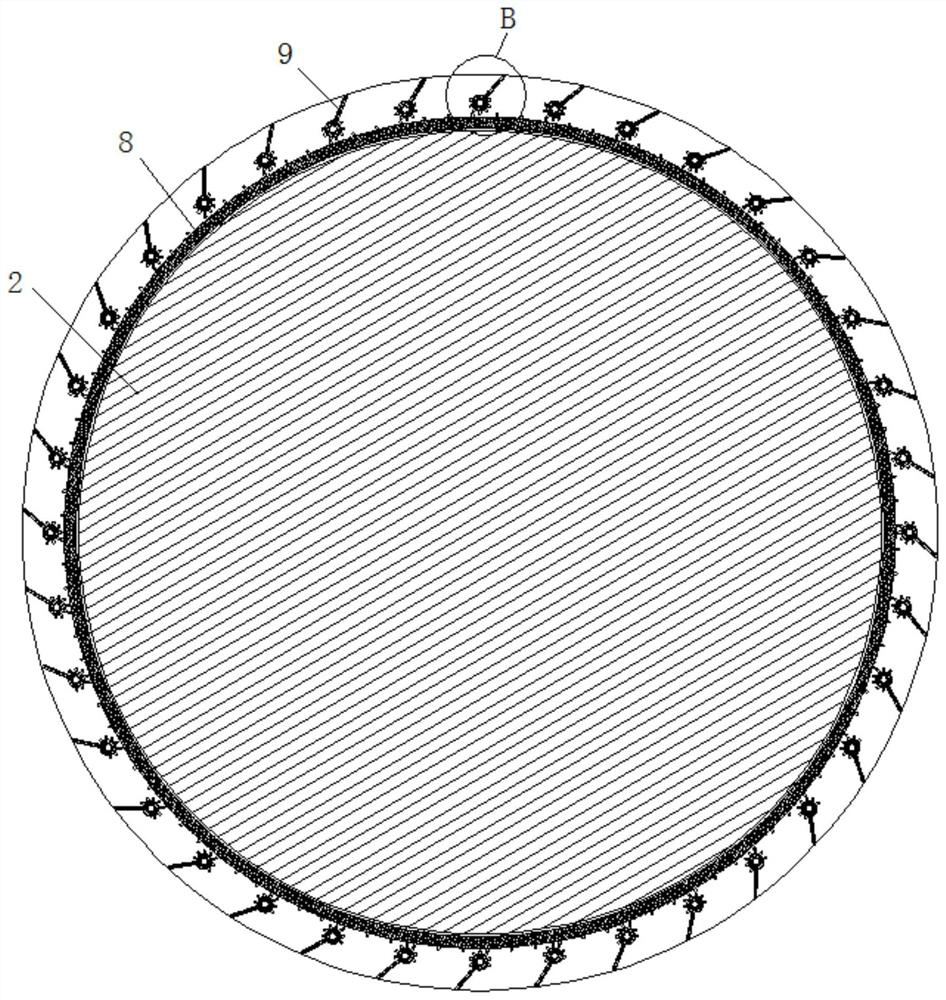

Crude oil bin cleaning system and method for FPSO (floating production storage and offloading) unit in offshore drilling platform

ActiveCN108394532AEfficient dischargeThorough cleaning effectTank vesselsTank cleaningSprayerWell drilling

The invention discloses a crude oil bin cleaning system and method for an FPSO (floating production storage and offloading) unit in an offshore drilling platform. The system comprises: a plurality ofbaskets positioned at the bottom of a crude oil bin; suction pumps arranged in the baskets to suck precipitate accumulated at the bottom of the crude oil bin; water sprayers arranged on the baskets close to their inlets and communicated with an external water supply system; vibrating motors arranged on the baskets and driving the baskets to vibrate under high frequency; a discharge pipe communicated with outlets of the suction pumps and used to discharge the sucked precipitate out of the crude oil bin; a separating tank for collecting a mixture discharged from the discharge pipe and for preliminarily filtering the precipitate, wherein the mixture is formed by mixing crude oil, the precipitate and water. The precipitate at the bottom of the crude oil bin can be effectively cleaned under high cleaning efficiency.

Owner:深圳市南星海洋工程服务有限公司

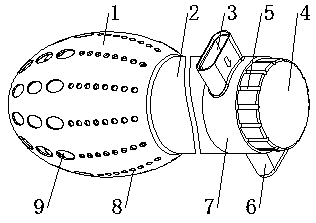

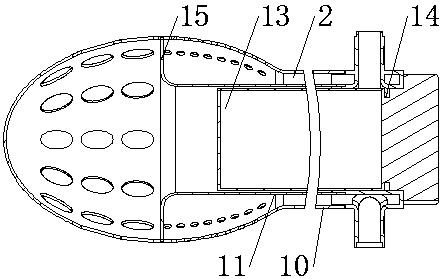

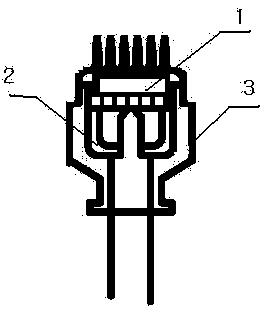

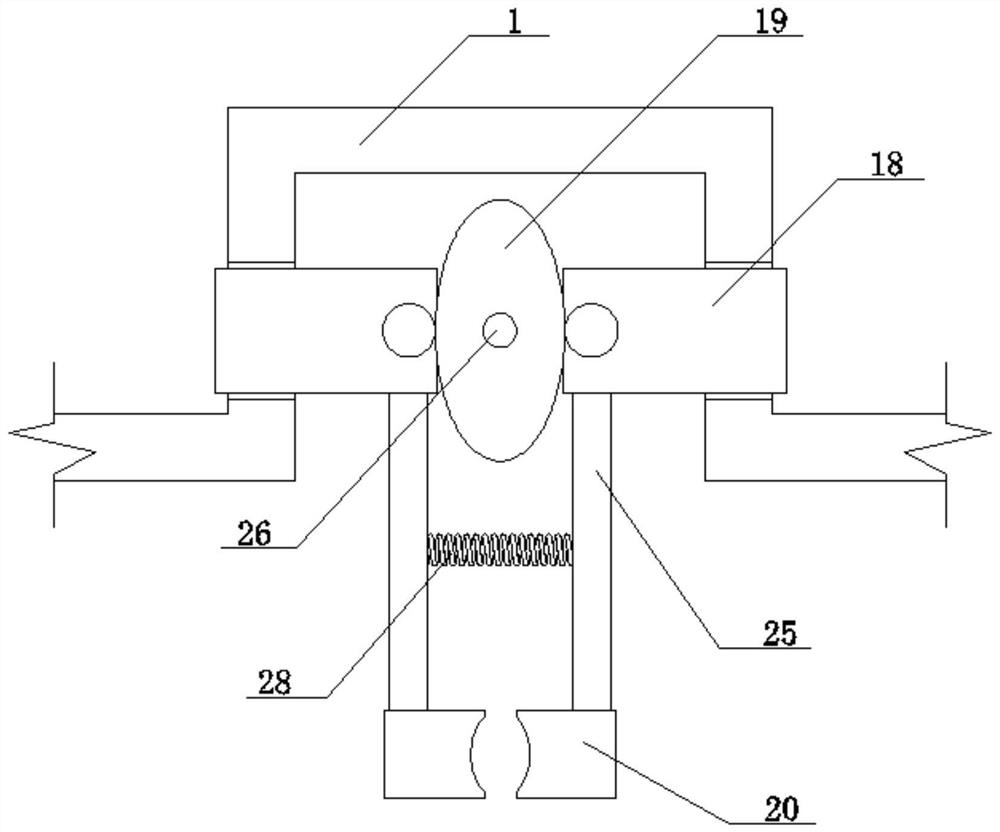

Clinical multi-head enhanced type stomach pump for gastroenterology department

InactiveCN110180048AEasy connectionThorough cleaning effectCannulasEnemata/irrigatorsGastric canalStomach pump

The invention discloses a clinical multi-head enhanced type stomach pump for gastroenterology department. The clinical multi-head enhanced type stomach pump comprises a balloon, wherein the balloon adopts an ellipsoidal structure, a partition board is fixedly arranged at the middle position in the balloon, a through hole is formed in the middle of the partition board, a mounting opening is formedin the upper end of the balloon, a gastric canal is fixedly arranged at the mounting hole in the upper end of the balloon, and comprises an outer canal and an inner canal, the outer canal is fixedly connected with the balloon, the inner canal penetrates through the mounting hole in the surface of the balloon, the inner canal is mounted in the through hole in the surface of the partition board in amatched manner, and a connecting body is mounted at the upper end of the gastric canal in a matched manner. The clinical multi-head enhanced type stomach pump for gastroenterology adopts the balloonstructure, through cooperation with the gastric canal with the inner canal and the outer canal, injection and pumping out of cleaning liquid are realized, the connecting body with a plurality of interfaces is arranged at the upper end of the gastric canal, thus the equipment is guaranteed to be convenient to connect, and the cleaning effect is thorough.

Owner:陈铭莲

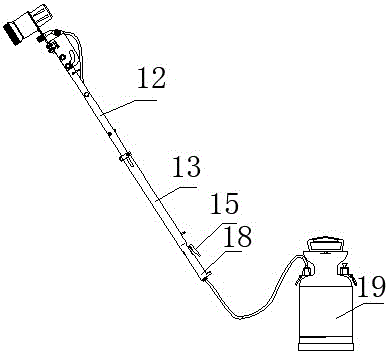

Handheld rotary vaginal cleaner

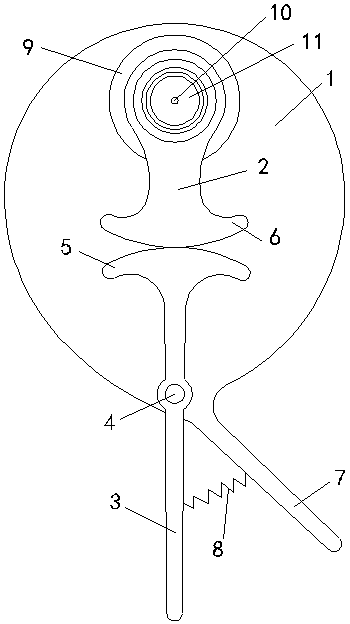

A handheld rotary vaginal cleaner comprises a fixed disc, a rotating disc, a cleaning rod and a liquid inlet tube. The rotating disc is mounted on the fixed disc, is connected with a rotating device and is provided with the cleaning rod, and the liquid inlet tube is inserted into the cleaning rod. The outer end of the liquid inlet tube is connected with an infusion bottle through an infusion apparatus. The cleaning rod extends into the vagina, and the liquid inlet tube is inserted into the cleaning rod. The cleaning rod rotates while medical agents such as physiological saline are delivered from the infusion bottle. The rotating cleaning rod cleans and brushes the inner wall of the vagina, and the physiological saline and other medical agents clean and sterilize the vagina while dirt is flushed out. The handheld rotary vaginal cleaner has the comprehensive functions of cleaning, debridement, nursing and drug administration, makes cleaning, debridement and nursing thorough, is clean, hygienic, is simple, convenient, quick to use and easy to operate, can be operated and used by a user without assistance from others, makes privacy protected very well and can be reused after sterilization.

Owner:刘汉俊

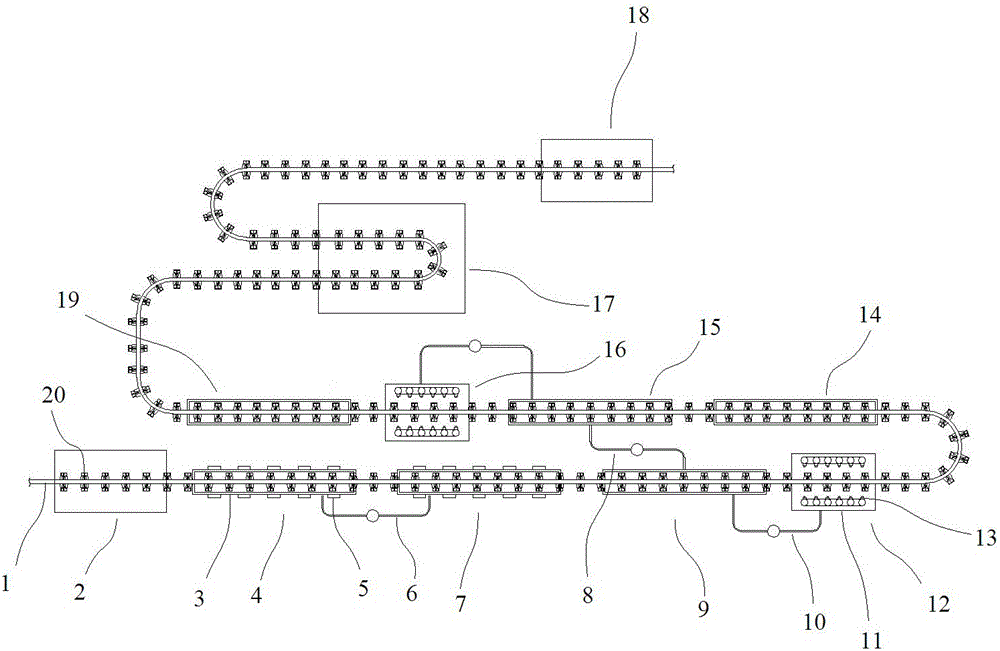

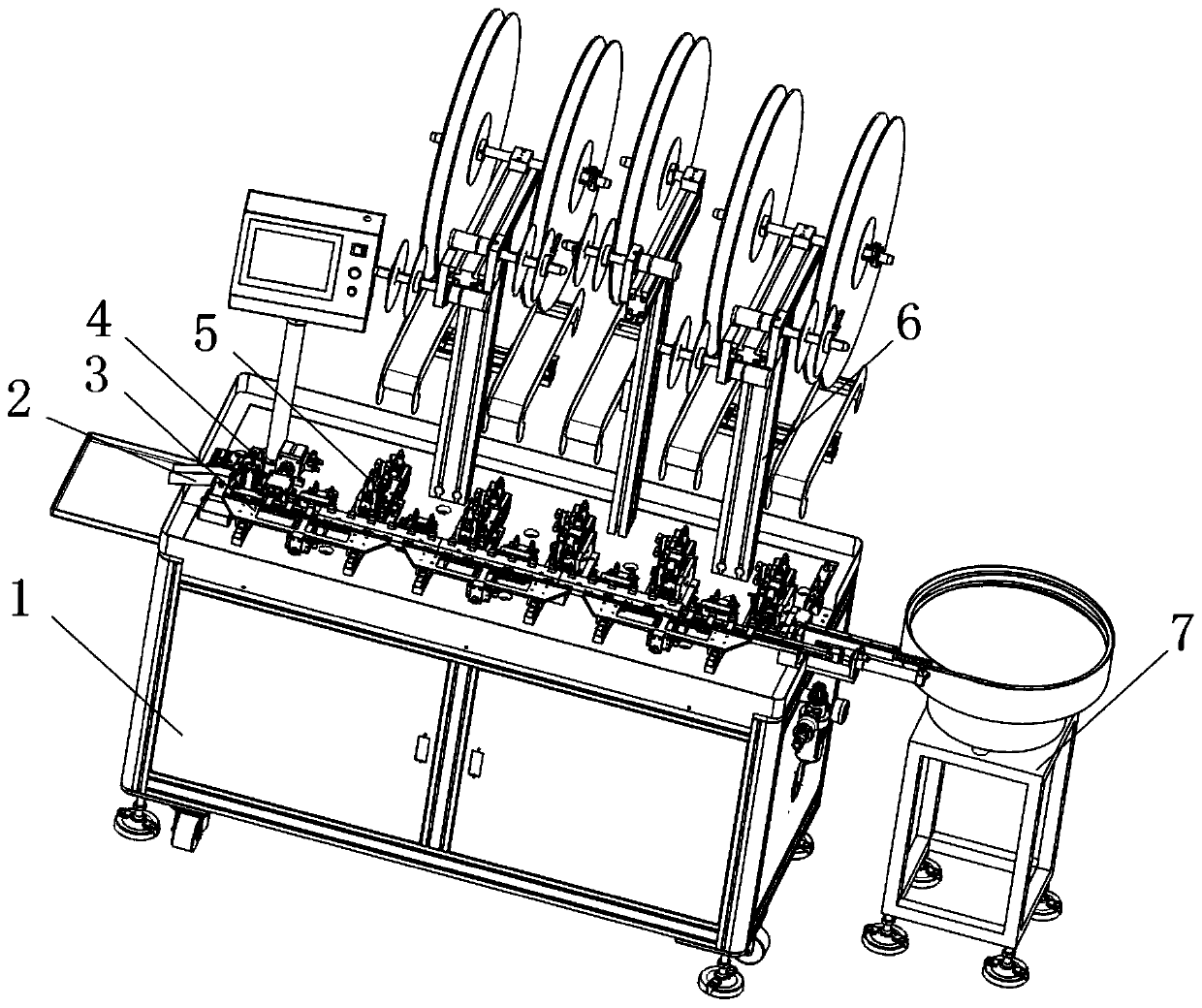

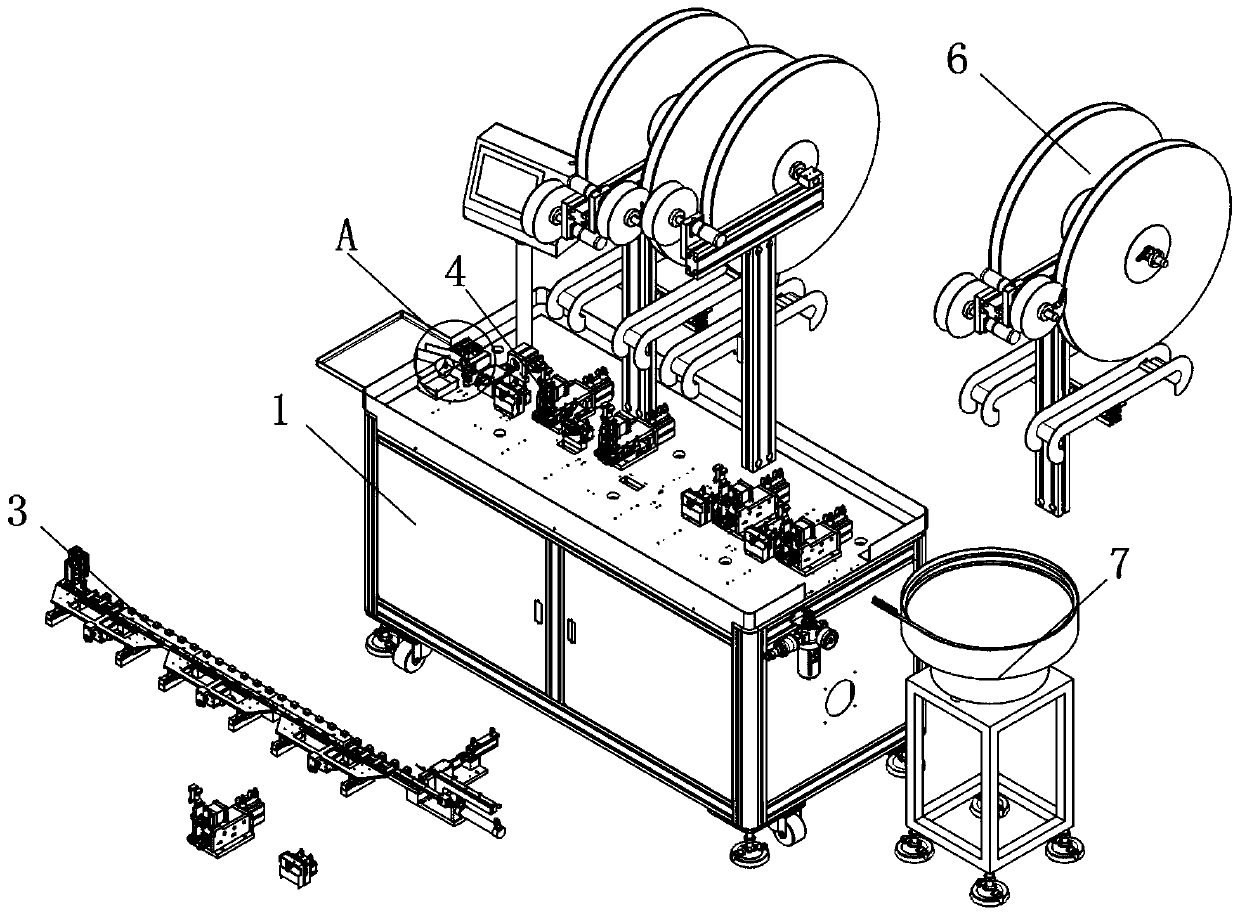

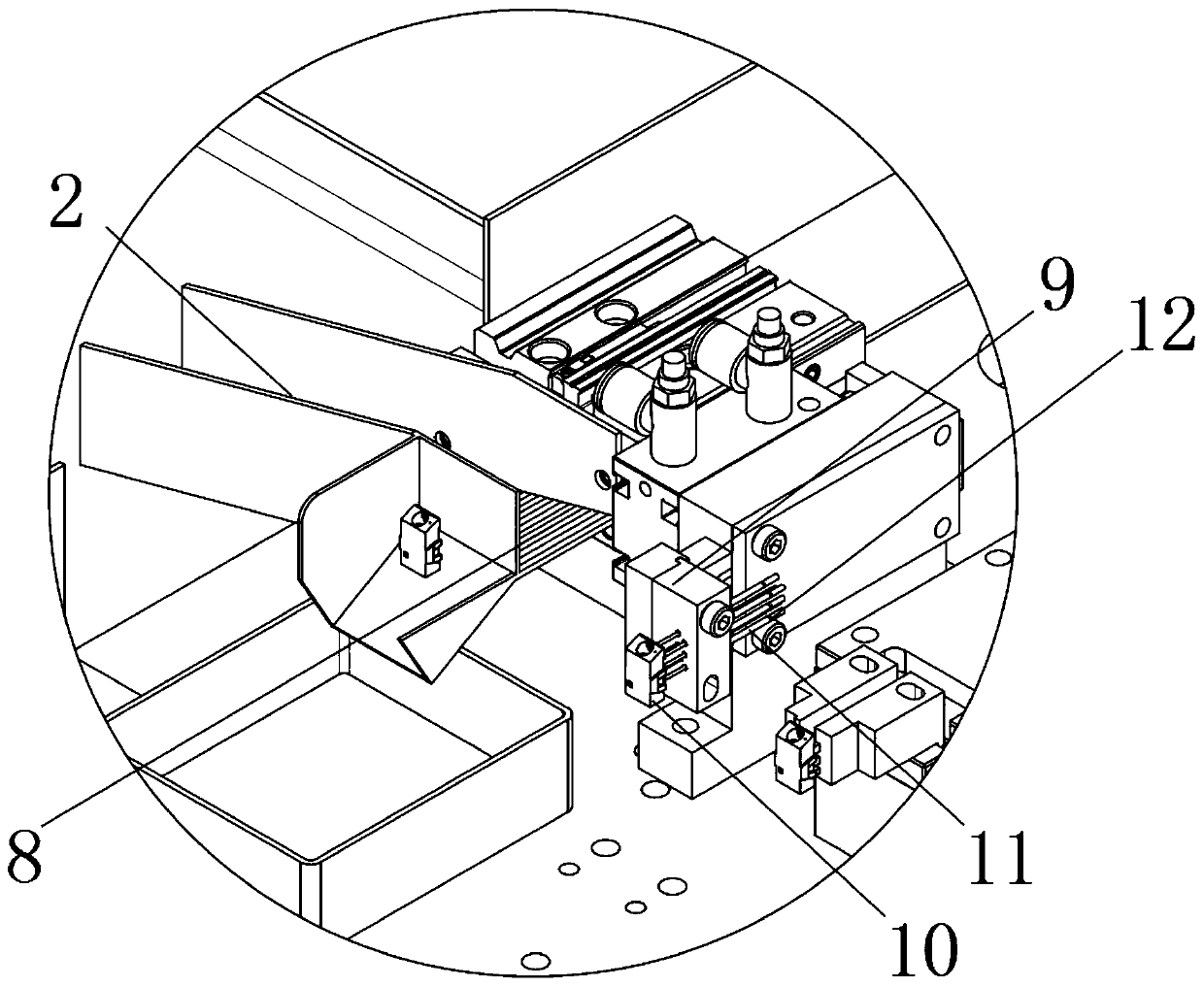

Hole cleaning and threading device used during machining of titanium alloy connector for aeronautic equipment

ActiveCN110497268AEasy to fixHigh degree of automationEdge grinding machinesGrinding carriagesHydraulic pumpEngineering

The invention discloses a hole cleaning and threading device used during machining of a titanium alloy connector for aeronautic equipment. The hole cleaning and threading device comprises a workbench,a connector hopper, a carrying disc, front cleaning tables, a rear cleaning table, a cable bearing disc and a loading disc. The workbench is of a cuboid-shaped structure, and the connector hopper isobliquely arranged at one end of the upper end face of the workbench. The carrying disc is arranged on one side of the connector hopper, and the multiple front cleaning tables are arranged on one sideof the carrying disc at equal intervals. The hole cleaning and threading device has the beneficial effects that first motors drive rotary polishing barrels to rotate to conduct polishing and removalburrs or projections in preformed holes in the connector, the effect that the inner walls of the preformed holes of the connector are smoother and rounder is ensured, and scraping damage between a metal cable and the hole walls of the connector is prevented during threading of the titanium alloy connector in the preformed holes; and in addition, the first motors are arranged in an equal-height mode, first hydraulic pumps correspondingly drive different-height first motors and the rotary polishing barrels to conduct hole cleaning treatment on the preformed holes in different-height positions onthe titanium alloy connector, and working adaptive universality of the hole cleaning and threading device is ensured.

Owner:SUZHOU XIANGYI NETWORK TECH

Square micro-needle massager manufacturing technical process

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

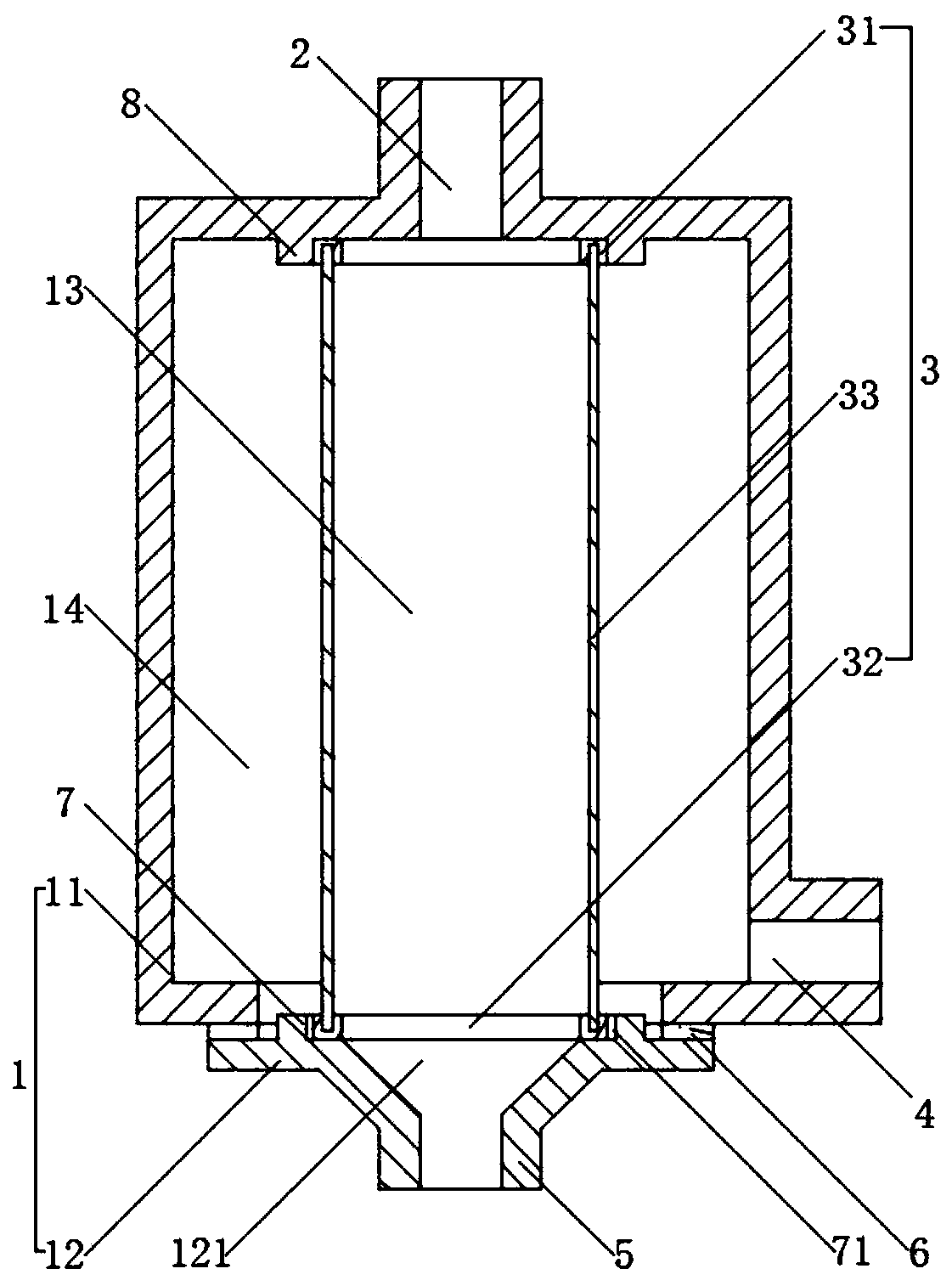

Self-sterilization type clinical tubular appliance flushing device for gynaecology and obstetrics

ActiveCN111790698AThorough cleaning effectImprove cleaning efficiencyHollow article cleaningEngineeringApparatus instruments

The invention relates to the technical field of medical instruments, in particular to a self-sterilization type clinical tubular appliance flushing device for gynaecology and obstetrics. The self-sterilization type clinical tubular appliance flushing device comprises a shell, a cleaning cavity is formed inside the shell, a cleaning assembly and a fixing assembly are arranged in the cleaning cavity, the cleaning assembly is further connected with a telescopic assembly and a rotating assembly, an opening is formed in the side wall of the shell, and a cover plate is arranged at the opening. By arranging the cleaning assembly, the tubular appliance can be flushed and brushed, so that a more thorough cleaning effect is achieved; meanwhile, the cleaning assembly is driven by the telescopic assembly and the rotating assembly so that the cleaning efficiency can be effectively improved; and by arranging the fixing assembly, the fixing assembly can be matched with a fixing groove to effectivelyand rapidly fix the tubular appliance, so that the cleaning operation is facilitated.

Owner:沈阳安联妇婴医院有限公司

Chemical sewage filtering device and clearing method thereof

PendingCN109052830APrevent leakageEasy loading and unloadingWater treatment parameter controlTreatment using aerobic processesDraining tubeSewage

The invention provides a chemical sewage filtering device and a clearing method thereof. The chemical sewage filtering device comprises a shell, wherein the upper end of the shell is connected with awater inlet pipe; an annular filtering plate is arranged in the shell; the annular filtering plate divides an inner cavity of the shell into a center cavity and a filtering cavity; the water inlet pipe is communicated with the center cavity; the filtering cavity is positioned around the center cavity and is communicated with the center cavity; a drain pipe communicated with the filtering cavity ismounted on the lower side of the cylindrical surface of the shell; the lower end surface of the shell is communicated with a slagging pipe communicated with the center cavity. The chemical sewage filtering device provided by the invention is convenient for cleaning the filtering plate.

Owner:盐城英贝吉环保科技有限公司

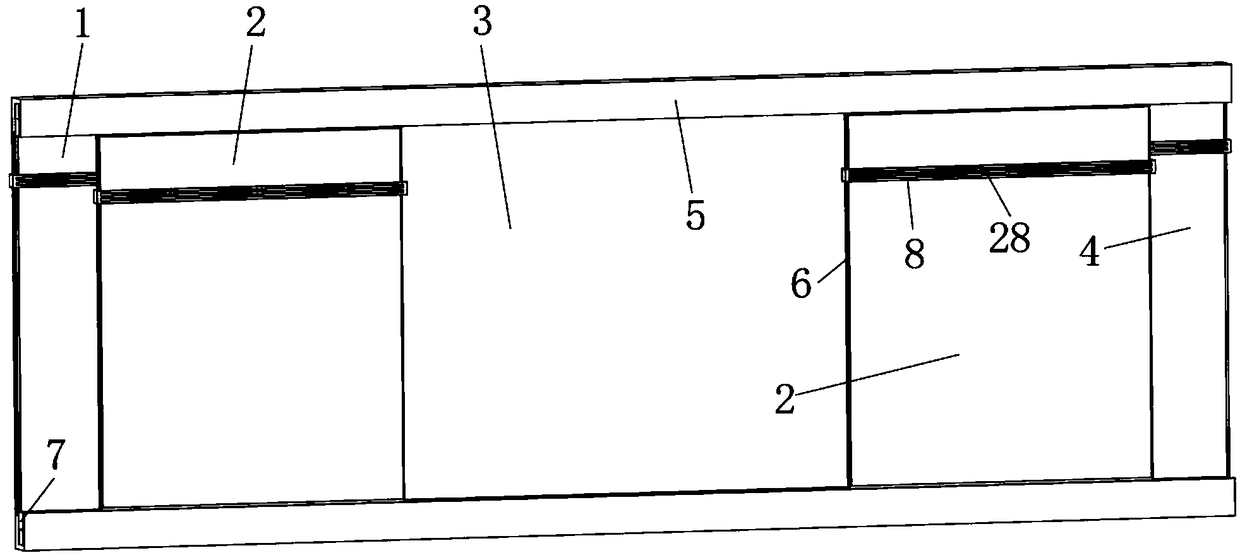

Push-pull blackboard for teaching

InactiveCN109228741ASimple structureEasy to installBoard cleaning devicesWriting boardsWhiteboardPush and pull

The invention provides a push-pull blackboard for teaching. U-shaped guide rail grooves with openings opposite to each other are formed in the upper end and the lower end of a mounting frame, a fixedblackboard A, an interactive electronic whiteboard and a fixed blackboard B are fixedly connected to the mounting frame, a push-pull blackboard body is arranged between the upper U-shaped guide rail groove and the lower U-shaped guide rail groove, a strong magnet A is fixedly connected to the groove bottom of each U-shaped guide rail groove, strong magnets B are fixedly connected to the upper endand the lower end of the push-pull blackboard body, the polarities of the opposite ends of the strong magnet B on the upper portion of the push-pull blackboard body and the corresponding strong magnetA are the same, guide components cooperating with the strong magnets B are arranged on the two side walls of the U-shaped guide rail grooves, iron sliding portal frames are arranged on the outer surfaces of the fixed blackboard A, the fixed blackboard B and the push-pull blackboard body, and two long-strip-shaped through holes used for fixing a rubber brush head and a felt brush head are formed in the top face of each portal frame. According to the blackboard, smooth push and pull can be achieved, and the blackboard can be cleaned rapidly and thoroughly.

Owner:JIANGSU UNIV OF TECH

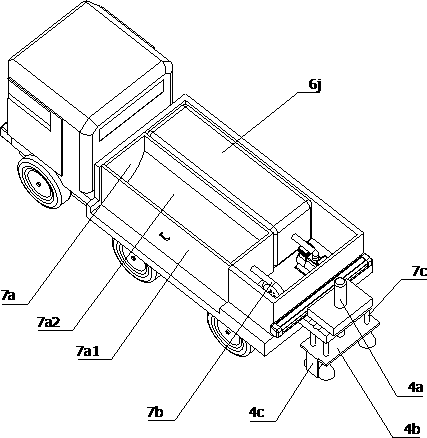

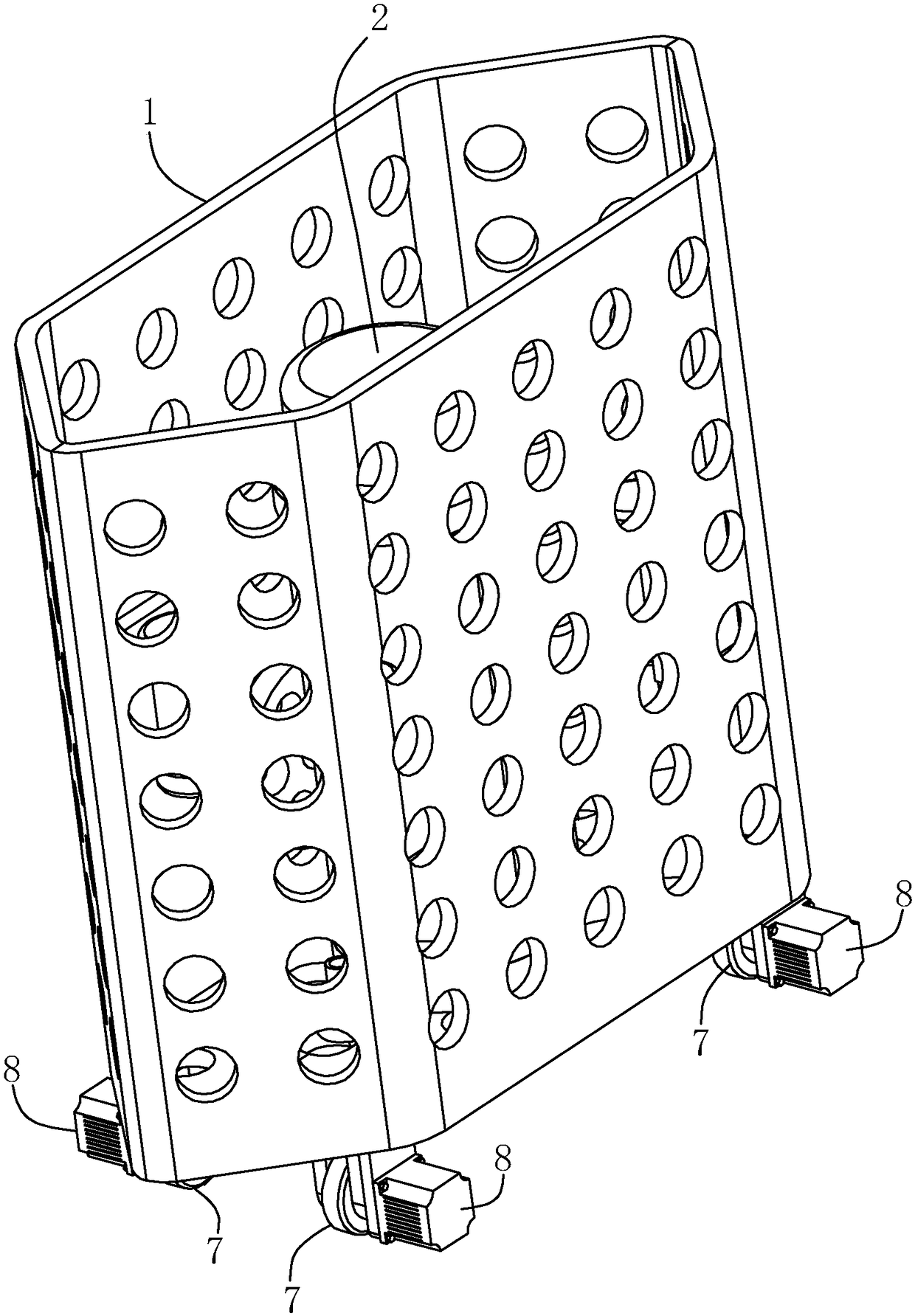

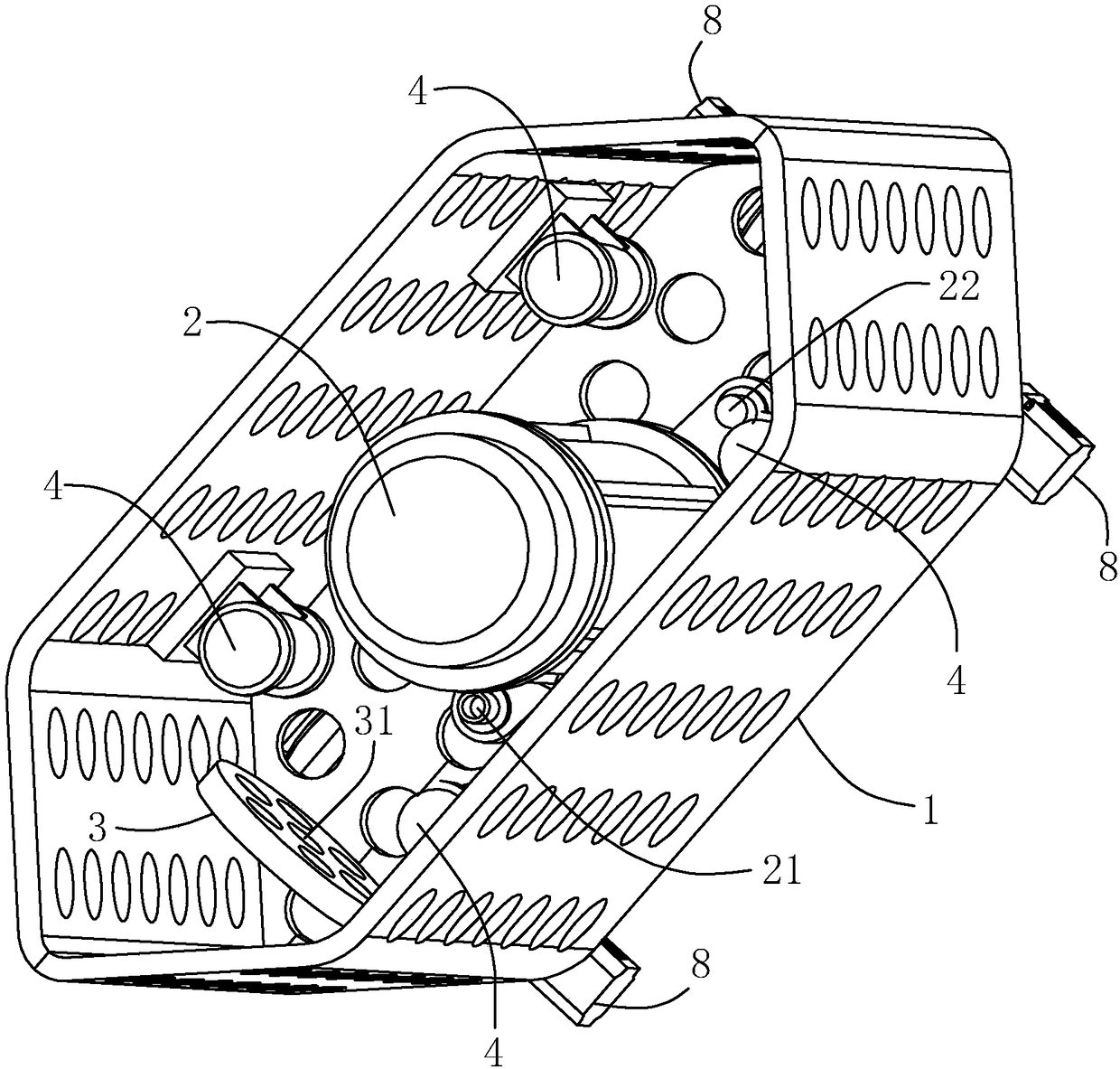

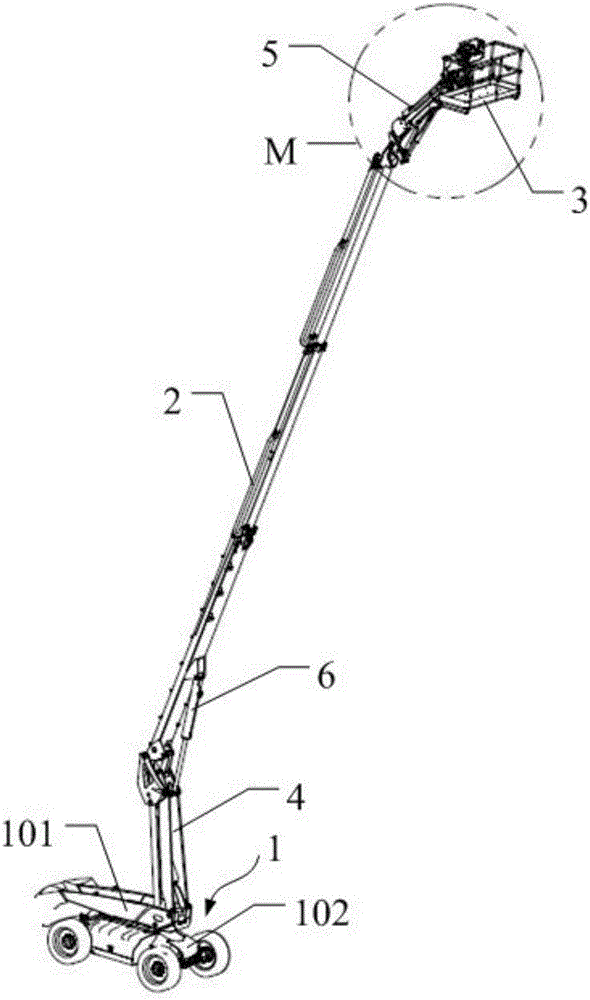

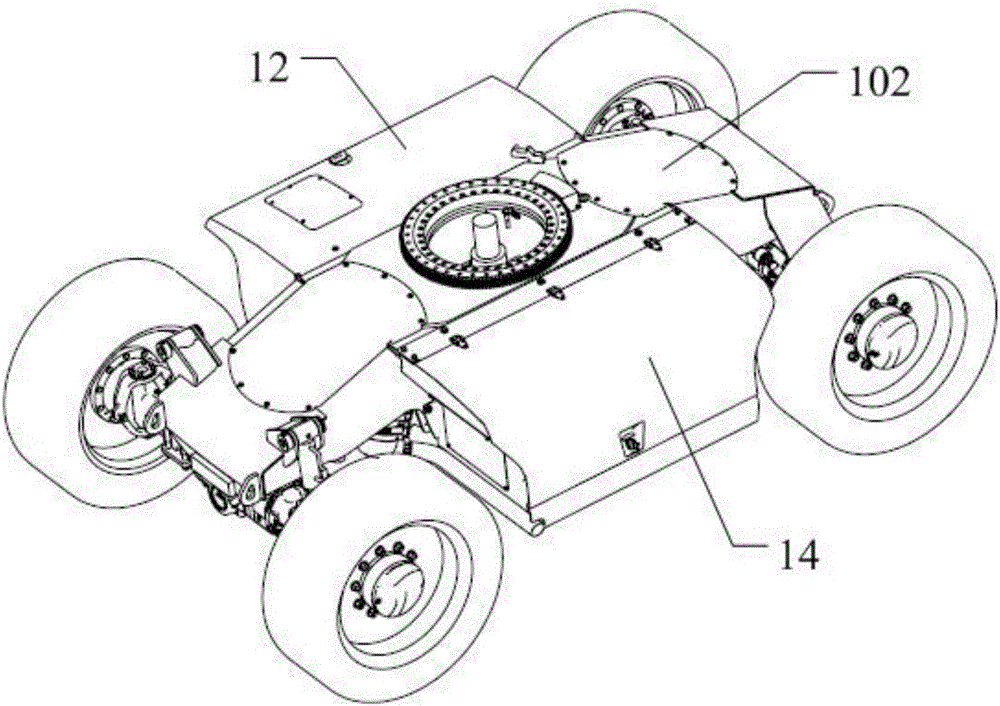

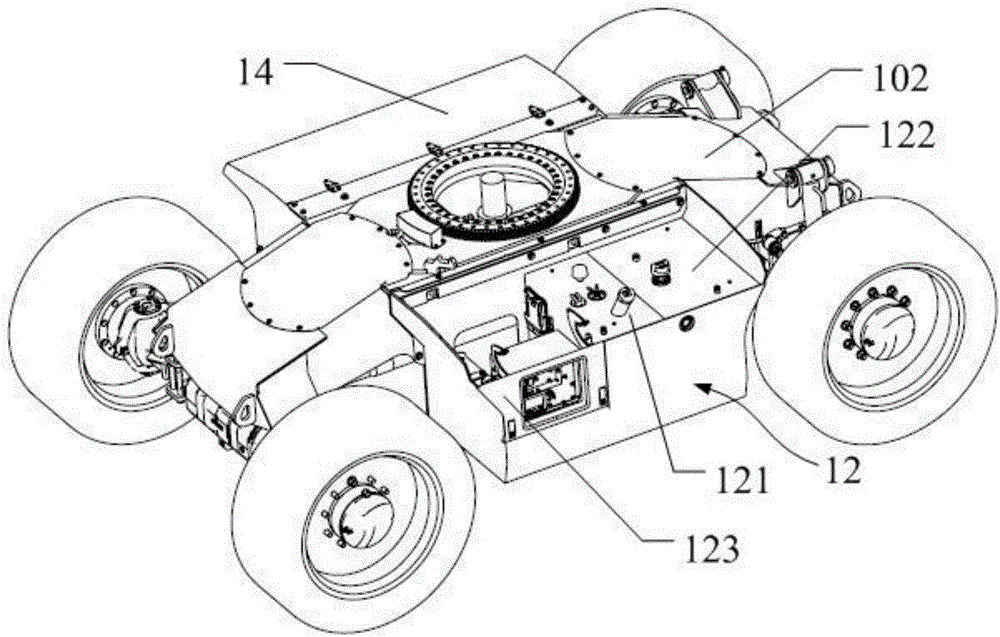

Power system with reverse blow-down capacity, vehicle body and aerial work platform

InactiveCN106347105ATo achieve the purpose of heat dissipationImprove cleaning efficiencyLifting devicesComponent optimizationCooling effectEngineering

The invention relates to the field of engineering machinery, in particular to a power system with reverse blow-down capacity, a vehicle body and an aerial work platform. The power system comprises a first box, an engine, a cooler and a fan assembly arranged between the engine and the cooler, wherein the first box is provided with vent holes; the engine, the cooler and the fan assembly are all arranged in the first box; the fan assembly comprises fan blades, a driving device for driving the fan blades to rotate and a control valve group for controlling the rotating direction of the driving device; a cooling connection pipe allowing circulation of a coolant is arranged between the engine and the cooler. Therefore, sundries or dust in the power system are cleaned automatically, the cleaning efficiency is higher, the labor intensity is lower, cleaning is more complete and the cleaning effect is better, the internal burning rate of the engine and the output power of the engine can be increased, pollutants in exhaust gas can be reduced, energy saving and environmental protection are realized, and a better cooling effect is realized.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

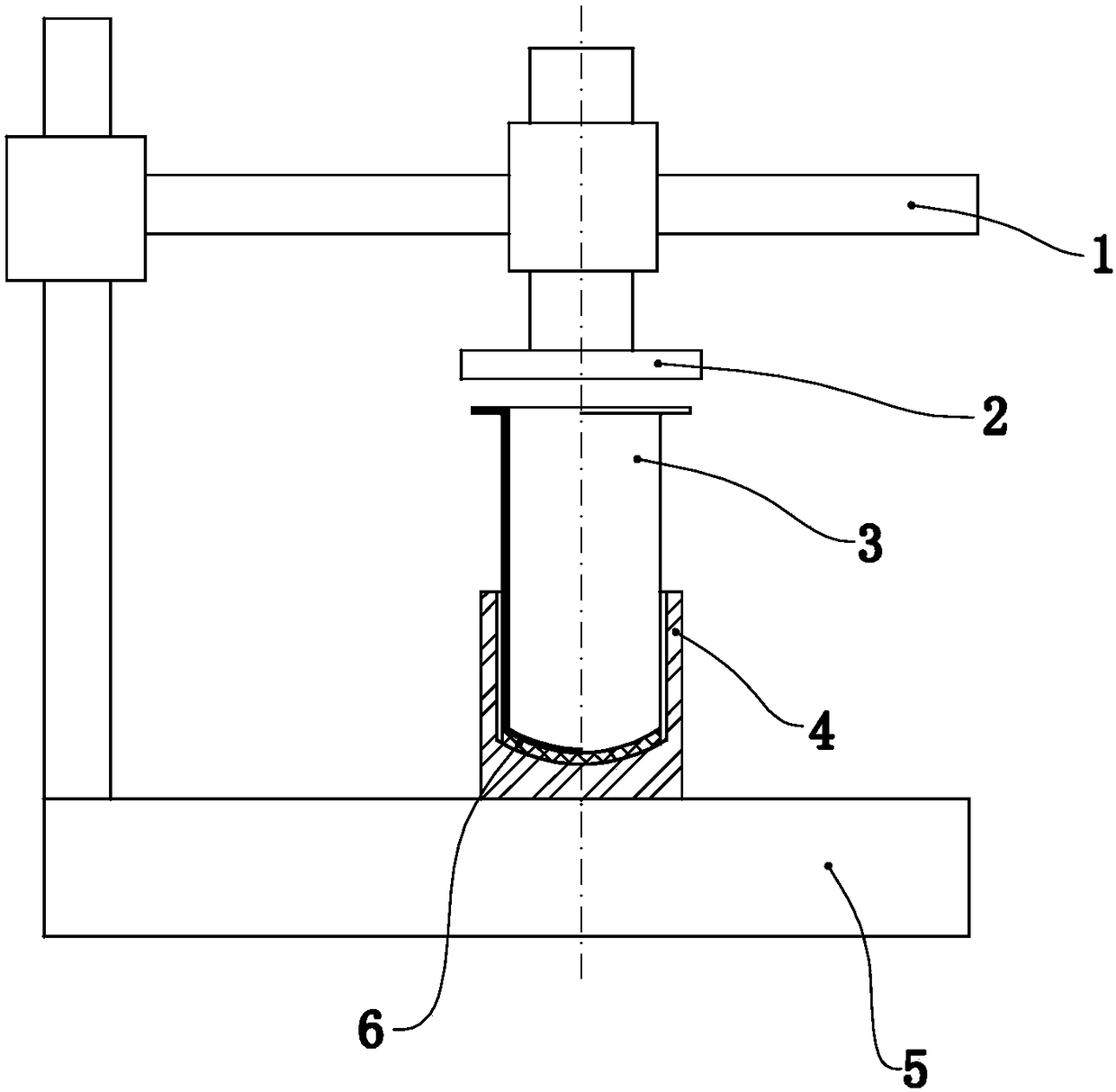

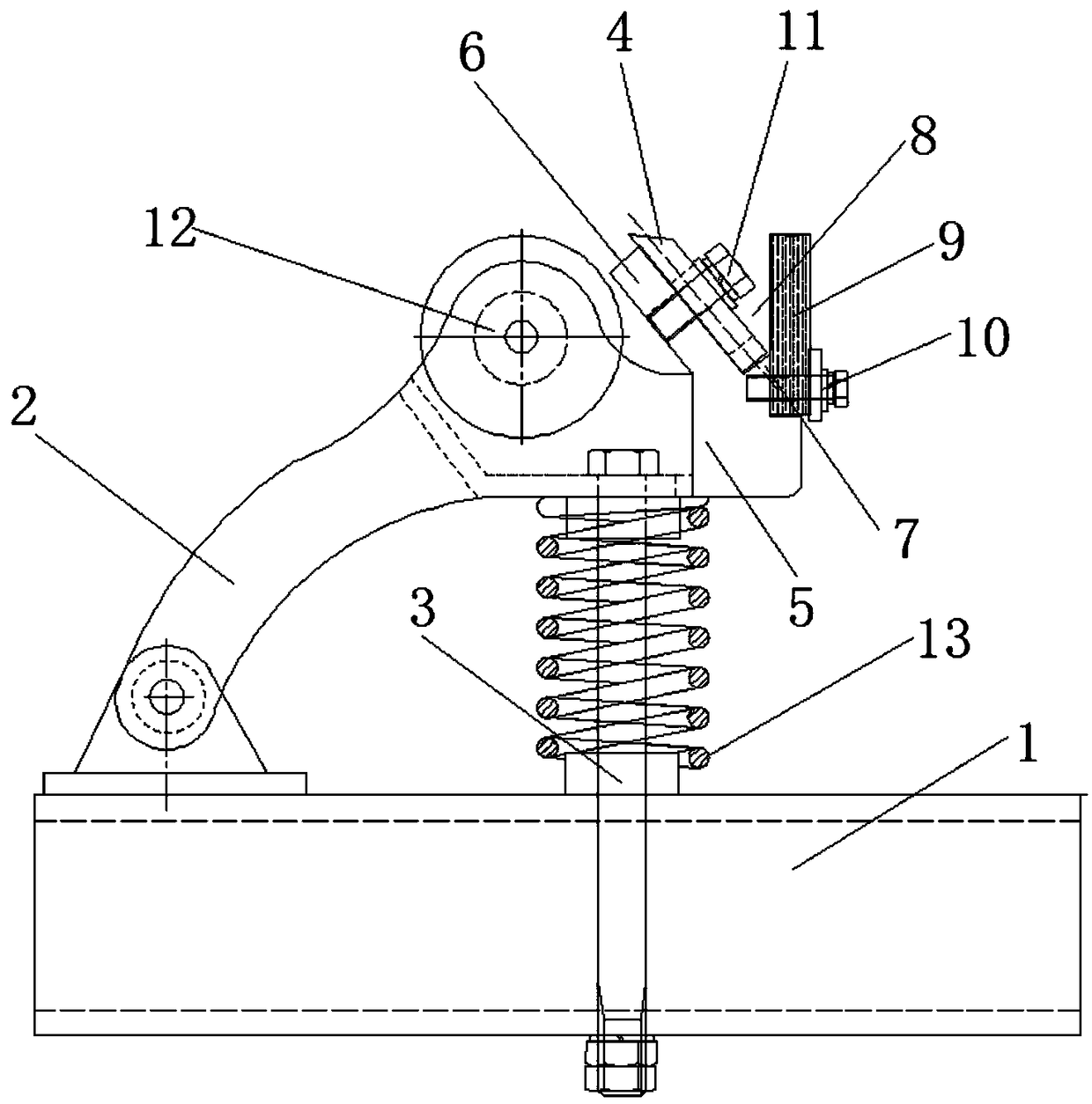

filter tank cleaner

The invention discloses a slag removal device for a tank opening of a filter, and belongs to the field of filter cleaning devices. The slag removal device comprises a pedestal, an assembly machine frame arranged on one side of the pedestal and a base arranged on the upper end face of the pedestal; the assembly machine frame comprises a vertical arm and a horizontal arm, the vertical arm is assembled on the pedestal, and the horizontal arm is assembled on the vertical arm in a rotating mode; a drive motor is arranged on the horizontal arm of the assembly machine frame, a rotation shaft of the drive motor is vertically arranged, and a grinding head is assembled at the lower part of the rotation shaft of the drive motor; the base is provided with a groove, an opening of the groove is arranged upwards, a rubber sheet is arranged at the inner bottom of the groove, and the groove is located below the grinding head. According to the slag removal device, mechanization of the slag removal work of the tank opening of the filter is realized, the efficiency of the slag removal work is improved, clearing is uniform and complete, and the clearing quality is high.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

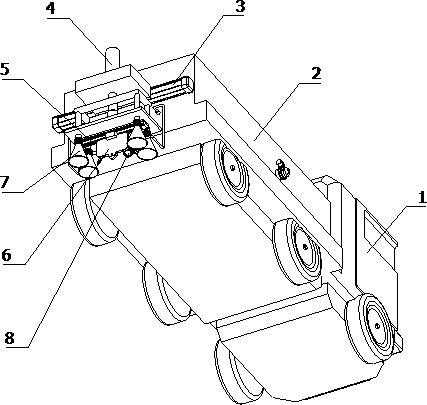

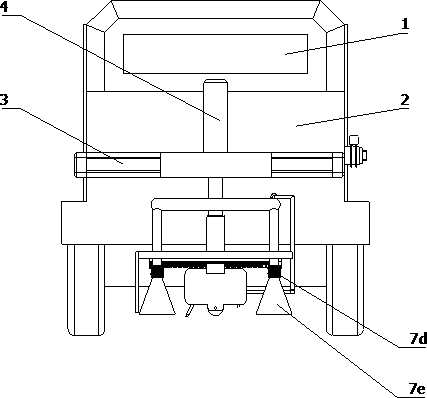

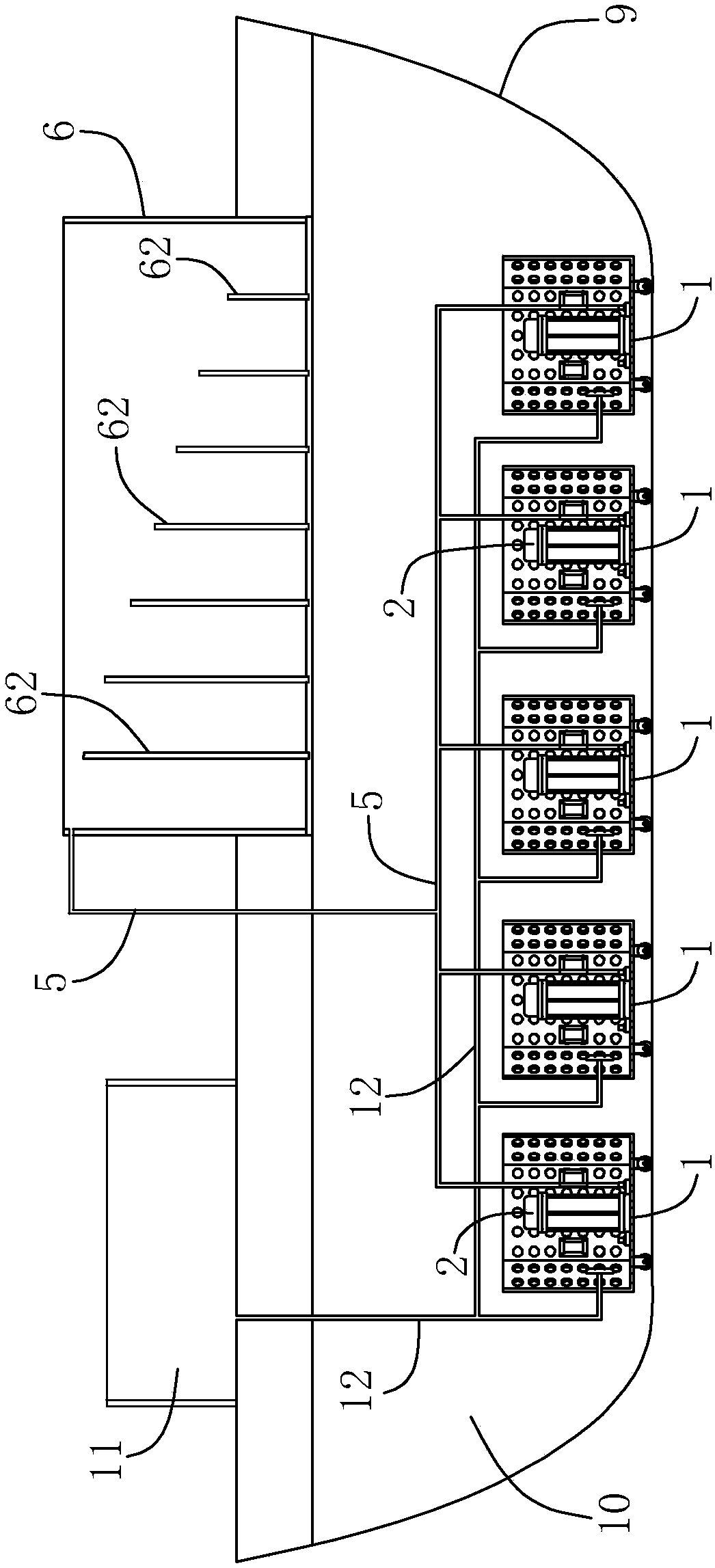

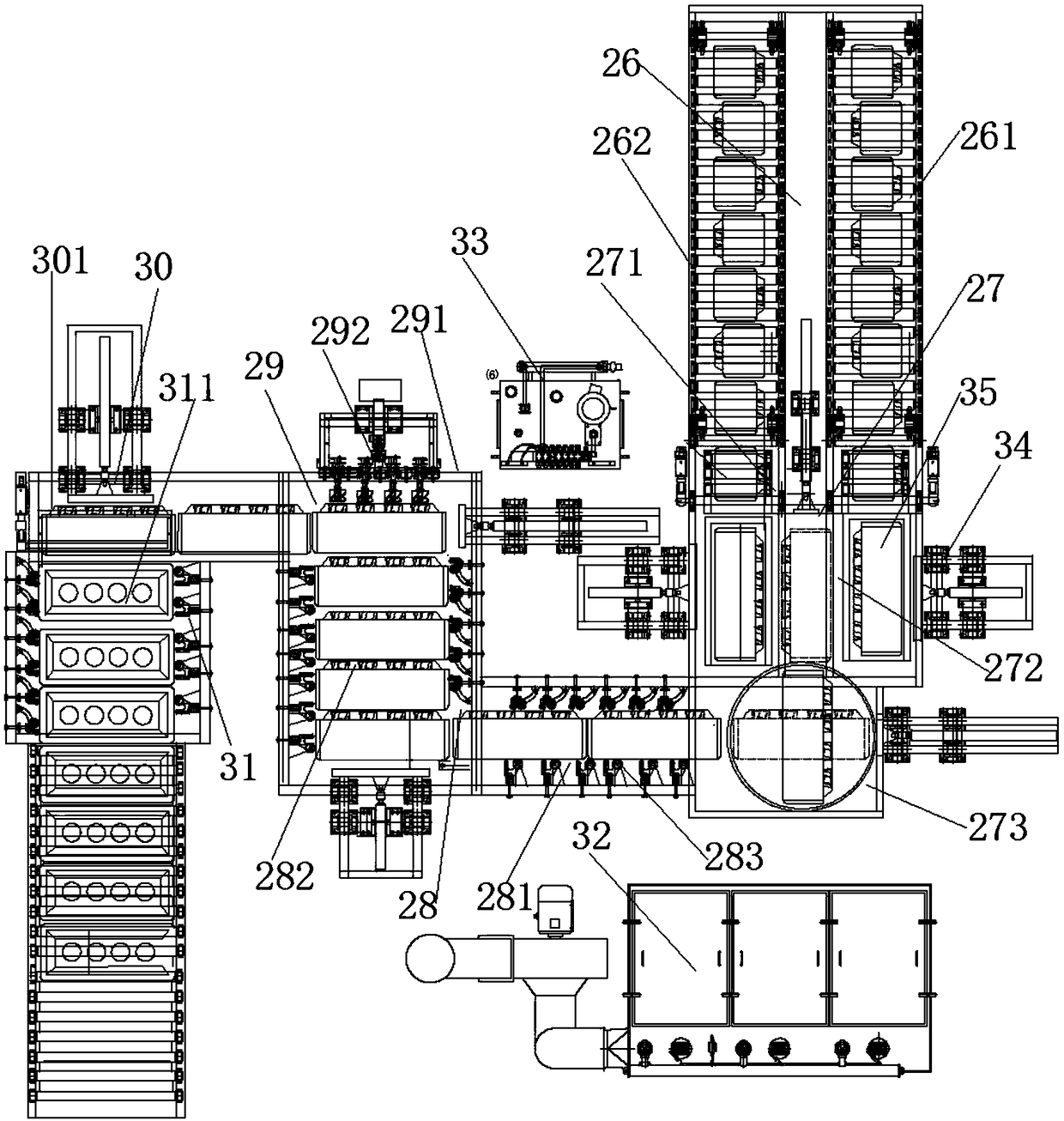

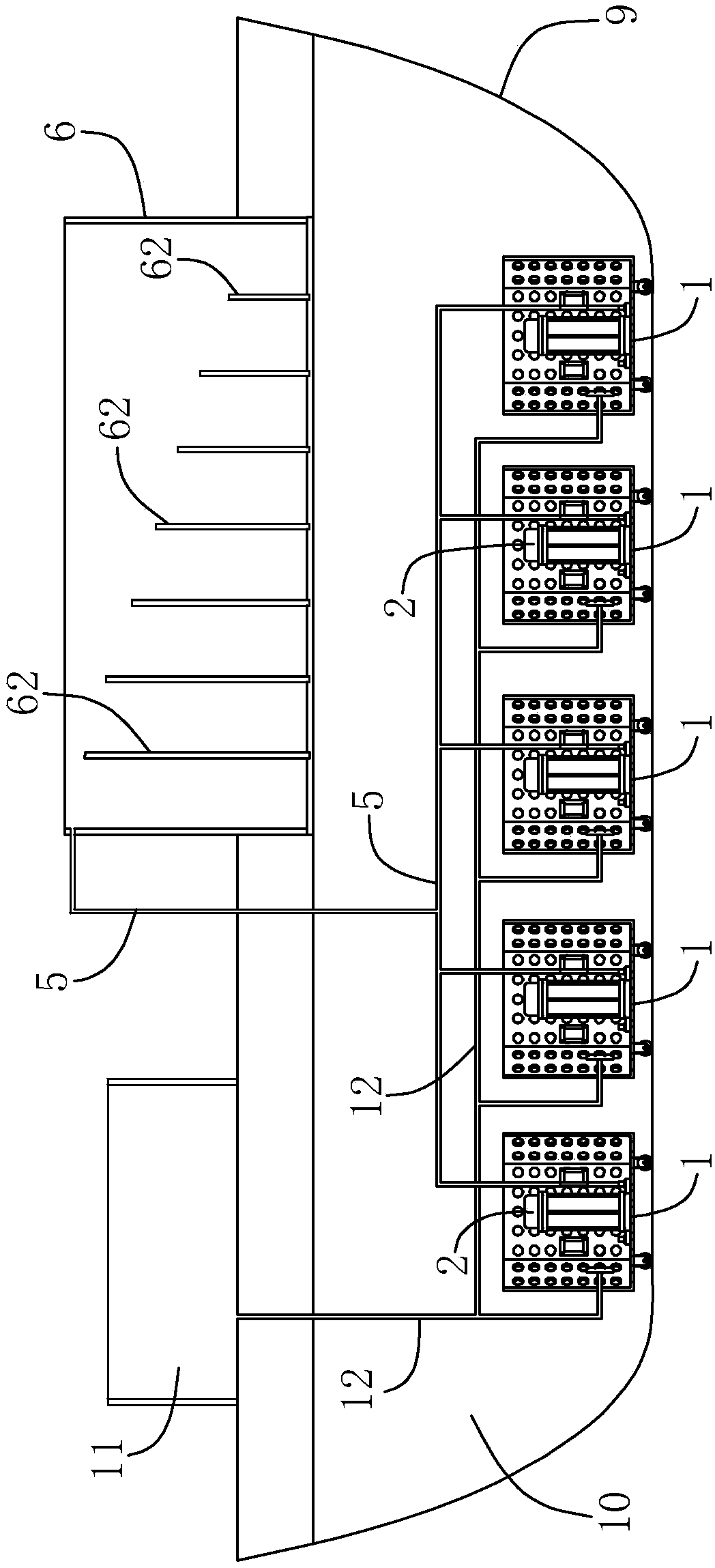

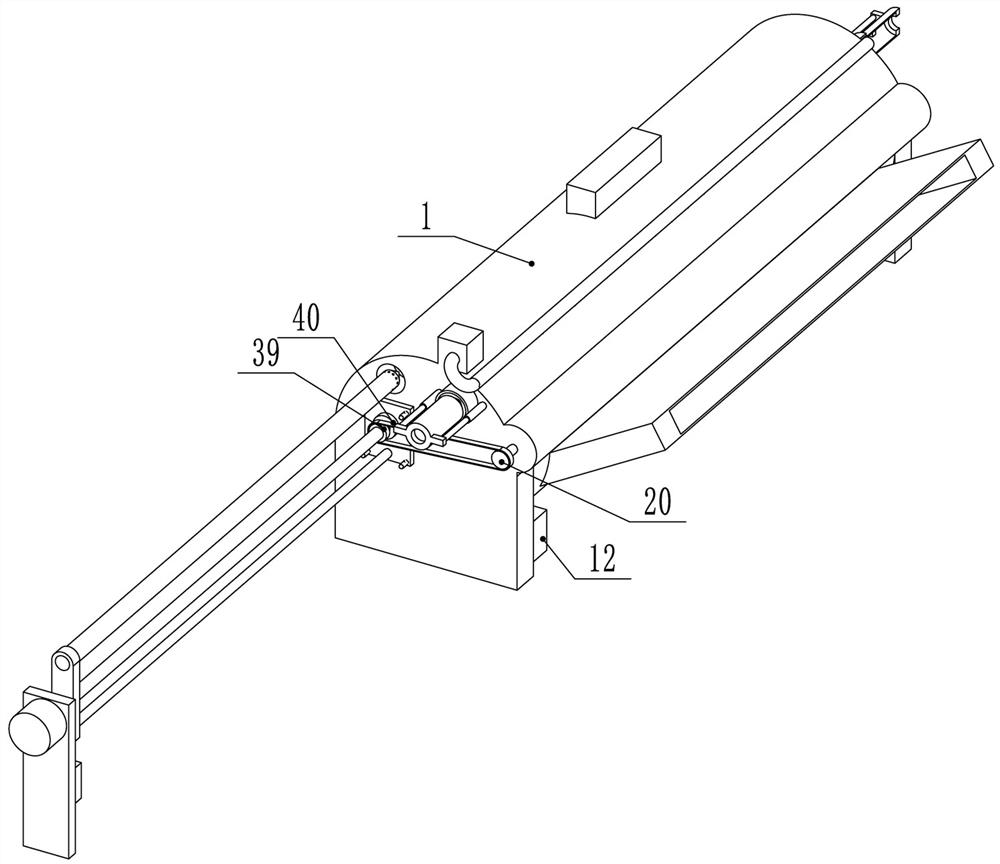

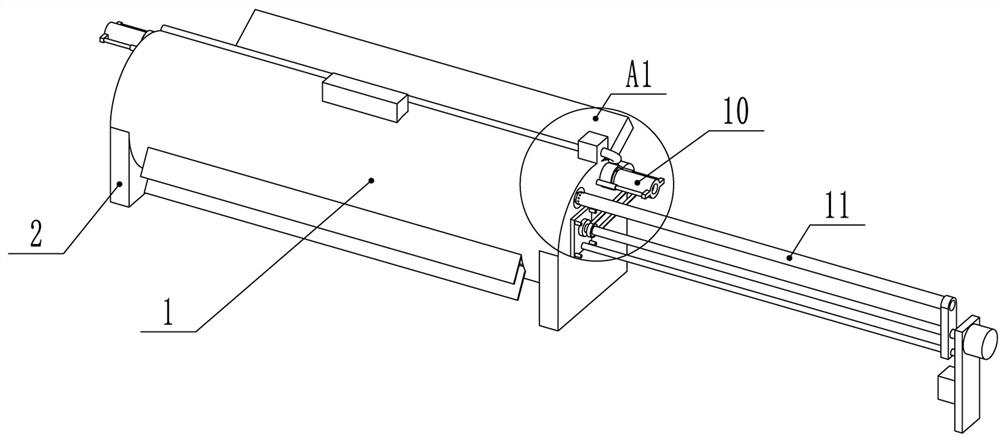

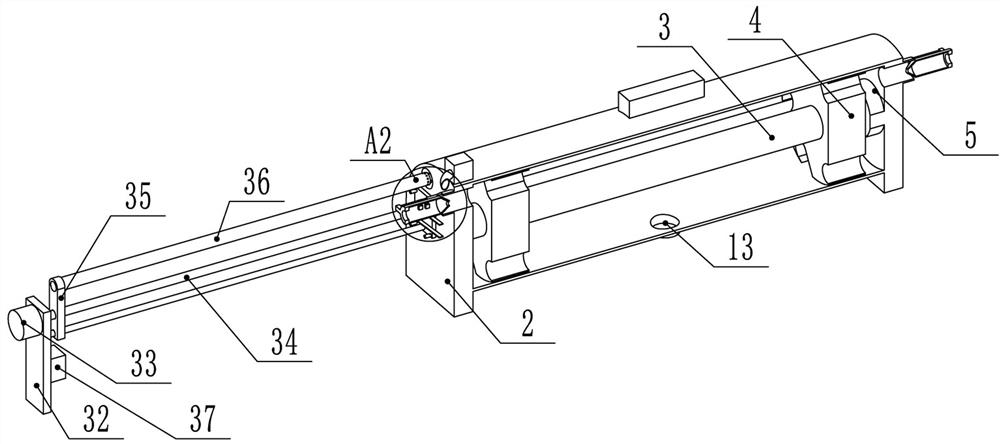

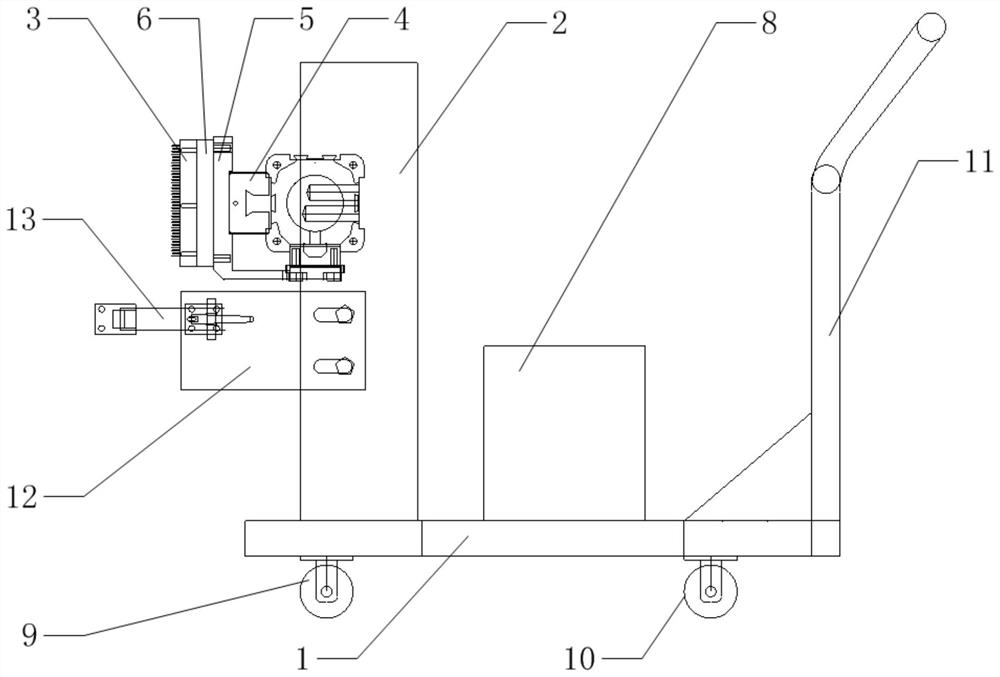

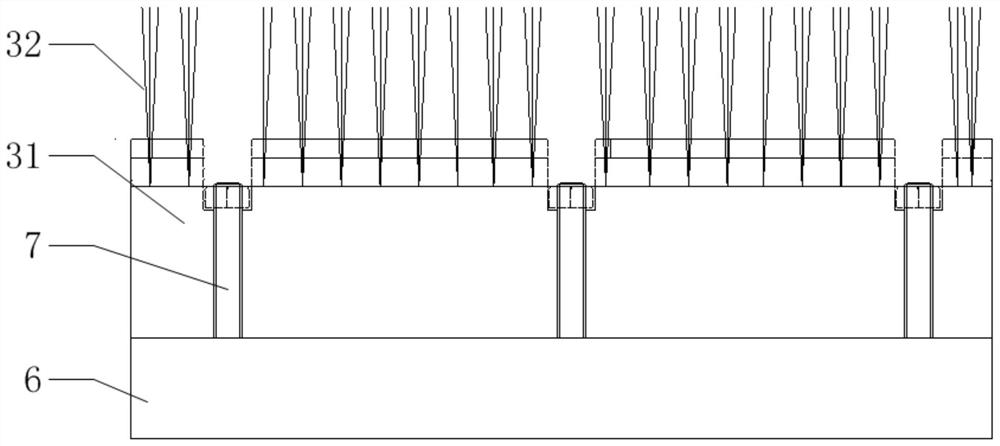

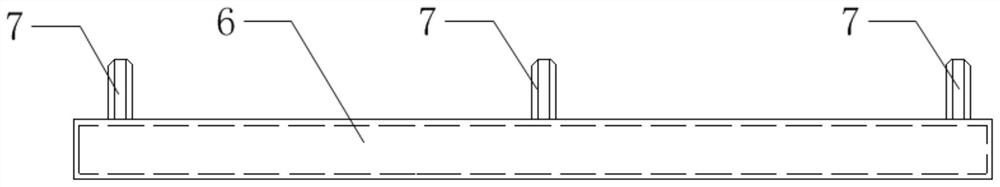

Automatic prebaked anode carbon block ungrouping and cleaning unit

The invention discloses an automatic disuniting and cleaning unit for prebaked anode carbon blocks. The disuniting and cleaning unit sequentially comprises a primary transportation section, a carbon block direction adjusting section I, a shape cleaning section I, a carbon bowl cleaning section, a carbon block direction adjusting section II and a shape cleaning section II in the anode carbon block conveying direction. Aimed at the defects that for a conventional anode carbon block disuniting and cleaning unit, the automation degree and working efficiency are low and the processing effect is bad, the invention provides the automatic disuniting and cleaning unit for the prebaked anode carbon blocks, which can adapt to the modern carbon production technology, is higher in automation degree and working efficiency, and is safe and reliable to use, the disuniting and cleaning unit is integrated, the design is reasonable, the treatment is ordered, the prebaked anode carbon blocks do not need to be hoisted by a travelling crane, the security coefficient is high, and the cleaning is thorough.

Owner:HAIAN YONGHENG VIBRATION MACHINERY CO LTD

Crude oil storage tank cleaning system and cleaning method for fpso in offshore drilling platform

ActiveCN108394532BEfficient dischargeThorough cleaning effectTank vesselsTank cleaningSprayerStorage tank

The invention discloses a crude oil bin cleaning system and method for an FPSO (floating production storage and offloading) unit in an offshore drilling platform. The system comprises: a plurality ofbaskets positioned at the bottom of a crude oil bin; suction pumps arranged in the baskets to suck precipitate accumulated at the bottom of the crude oil bin; water sprayers arranged on the baskets close to their inlets and communicated with an external water supply system; vibrating motors arranged on the baskets and driving the baskets to vibrate under high frequency; a discharge pipe communicated with outlets of the suction pumps and used to discharge the sucked precipitate out of the crude oil bin; a separating tank for collecting a mixture discharged from the discharge pipe and for preliminarily filtering the precipitate, wherein the mixture is formed by mixing crude oil, the precipitate and water. The precipitate at the bottom of the crude oil bin can be effectively cleaned under high cleaning efficiency.

Owner:深圳市南星海洋工程服务有限公司

A portable small advertising cleaning machine

InactiveCN104874559BAdjustable angleShort working hoursCleaning using toolsSprayerUltimate tensile strength

Owner:LUOYANG INST OF SCI & TECH

Perfluoropolyether functional intermediate purification device

ActiveCN112250857AControl the amount of feedAdequate responseChemical industryPerfluoropolyetherElectric machinery

The invention discloses a perfluoropolyether functional intermediate purification device which comprises a base, a bearing box, a lifting mechanism, a second valve, a motor and an air exhaust and cleaning mechanism; wherein the bottom of the bearing box penetrates through a first bearing frame to be in threaded connection with a fastener, a heating plate is arranged on the inner side of an electric heater, and the lifting mechanism is fixed to a second bearing frame; a feeding channel is fixed to the top of the top cover, the second valve penetrates through the top cover to be connected with the bottom of the feeding channel, the bottom of the feeding channel is rotationally connected with a stirring column, and the air exhausting and cleaning mechanism is fixed to the left side and the right side of the top of the top cover. According to the perfluoropolyether functional intermediate purification device, before the device is used, a connecting hose and an external air pump need to beconnected together through a connector, and a perfluoropolyether functional intermediate is obtained after raw materials and auxiliaries fully react; after the power of an electric heater is increased, the temperature of a heating plate is increased, and thereby small molecular impurities can be volatilized into gas to be separated from perfluoropolyether after being in contact with the heating plate.

Owner:太仓中化环保化工有限公司

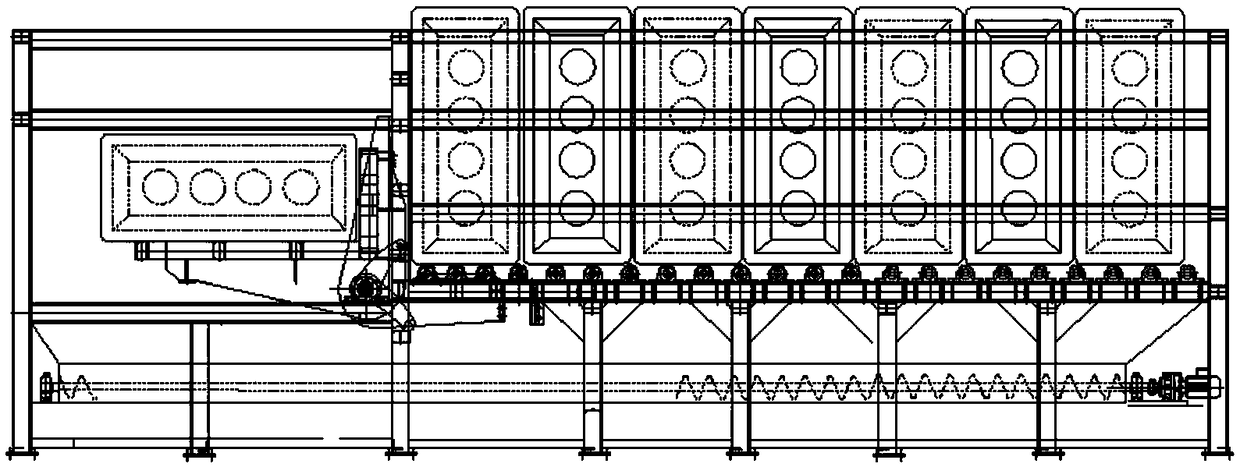

Washing device for textile printing and dyeing cloth

PendingCN114517372AHigh efficiency cleaningThorough cleaning effectTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringEnvironmental geology

The invention discloses a washing device for textile printing and dyeing cloth, and the washing device comprises a cleaning device which is provided with cleaning water for cleaning the passing cloth; the water inlet end of the filtering device is communicated with the cleaning water in the cleaning device so as to filter the cleaning water; the heating device is communicated with the water outlet end of the filtering device so as to heat the cleaning water entering the heating device; the air compression device is communicated with the heating device, so that compressed air is contained in the cleaning water; the spraying device is provided with a water vapor inlet pipe, a main water vapor pipe communicated with the water vapor inlet pipe and branch water vapor pipes communicated with the main water vapor pipe, the bottom ends of the branch water vapor pipes are communicated with spraying pipes, and the spraying pipes are arranged between the cloth guide rollers to spray cloth. According to the washing device for the textile printing and dyeing cloth, washing water is recycled, the cloth is subjected to two washing processes of water bath washing and high-pressure spraying water vapor washing, and washing with higher efficiency is achieved.

Owner:博格曼(江苏)纺织科技有限公司

Automatic cleaning device for oil pipe for oil field

InactiveCN113351585AThorough cleaning effectPrevent floodingHollow article cleaningDirt cleaningOil fieldElectric control

The invention discloses an automatic cleaning device for an oil pipe for an oil field. The automatic cleaning device comprises a protective cover, supports, a first servo motor and an electric control box, wherein the supports are installed at the two ends of the protective cover; the electric control box is installed on the side faces of the supports; the first servo motor is installed at one side of the inner wall of the protective cover; a mounting shaft is installed on an output shaft of the first servo motor; a pipe frame is arranged on the mounting shaft; and a pipe inlet end corresponding to the pipe frame is arranged at one side of the protective cover. According to the device, the oil pipe is cleaned in the protective cover, so that the situation that water used in the cleaning process flows around can be effectively prevented, and pollution to the surrounding environment is avoided; a spraying frame and a brushing frame are combined for use, so that the exterior of the oil pipe can be cleaned more thoroughly; and a steam cleaning structure and an inner pipe flushing structure are combined for use, so that the interior of the oil pipe can be cleaned more thoroughly.

Owner:LUOYANG GONGHANG MECHANICAL TECH CO LTD

Tobacco cutter row chain cleaning device

PendingCN113415605AReduce labor intensityEliminate slippageTobacco treatmentCleaningMechanical engineeringIndustrial engineering

The invention discloses a tobacco cutter row chain cleaning device which comprises a base and a fixing frame installed at the front end of the upper face of the base. A driving mechanism and a locking mechanism are installed at the front end of the fixing frame, the driving mechanism is provided with a brush and drives the brush to reciprocate, and the locking mechanism is detachably connected with a tobacco cutter body and can lock the relative position of the fixing frame and the tobacco cutter body, so that the brush is in contact with the tail end of a row chain. By means of the device, manual cleaning is replaced by automatic cleaning, the cleaning difficulty is lowered, the labor intensity of operators is relieved, the cleaning effect is thorough, operation is convenient, efficient, rapid and safe, maintenance personnel do not need to frequently disassemble and clean, the maintenance period is prolonged, the labor intensity of the maintenance personnel is relieved, and the slipping phenomenon of the row chain in the material conveying process is eliminated, so that the shredding width and the product quality are ensured.

Owner:JILIN TOBACCO IND

An edible oil storage tank breathing valve capable of automatically cleaning the filter membrane

ActiveCN110529639BAvoid easy cloggingReduce cloggingDispersed particle filtrationLarge containersEnvironmental engineeringEdible oil

The invention provides an edible oil storage tank breathing valve capable of automatically cleaning the filter membrane, comprising a valve body, an exhalation valve disc and a rain cover are installed on the top of the valve body, a central rod is fixedly connected to the bottom of the rain cover, and the exhalation valve disc There is a support ring fixedly connected to the bottom of the support ring, a filter membrane is laid on the support ring, a turntable is connected to the inside of the exhalation valve disc and located outside the central rod, and a swivel sleeve is installed on the outside of the turntable, and the interior of the exhalation valve disc is located on the outside of the swivel sleeve. The outer rotary connection has evenly distributed scrapers. A filter membrane is installed under the exhalation valve disc to prevent small particles in the external environment from entering the inside of the cooking oil storage tank. When the exhalation valve disc moves up and down to adjust the pressure, the scraper in the exhalation valve disc rotates and stretches out, The filter membrane is scraped to automatically remove the debris adhering to the filter membrane, reducing the possibility of the filter membrane being blocked, improving the safety of the breathing valve, and the multi-stage scraper can clean the filter membrane more thoroughly .

Owner:江苏复森特种阀门有限公司

A hole clearing and threading device for machining titanium alloy connectors for aviation equipment

ActiveCN110497268BEasy to fixHigh degree of automationEdge grinding machinesGrinding carriagesAviationElectric machinery

Owner:SUZHOU XIANGYI NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com