Square micro-needle massager manufacturing technical process

A technological process and massager technology, applied in the directions of micro-needles, needles, medicines, etc., can solve the problems of inconvenient disinfection and cleaning, hidden dangers, high product prices, etc., achieve thorough disinfection and cleaning, improve practical effects, and appearance. Smooth and neat effect

Inactive Publication Date: 2014-12-24

QINGDAO KANGWEILONG COMMODITY COMPANY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is inconvenient to disinfect and clean, which affects the use, and the aesthetics of the product is greatly reduced due to the impact of the gap

And due to the impact of the structure, the original product can only be a one-time consumer product, which makes the product expensive; and the original microneedle roller can not be sterilized better because it cannot be sterilized by high temperature and high pressure, which will affect the beauty and beauty. The plastic surgery process brings the hidden danger of infection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

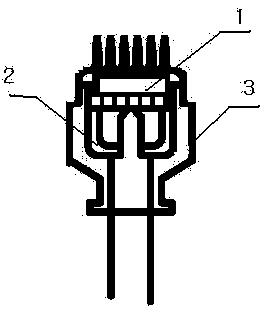

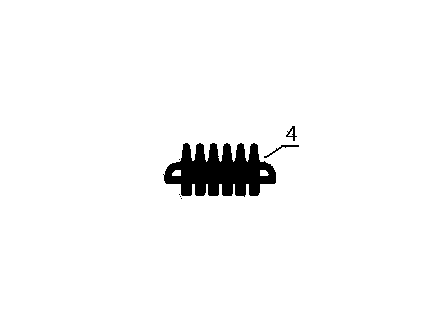

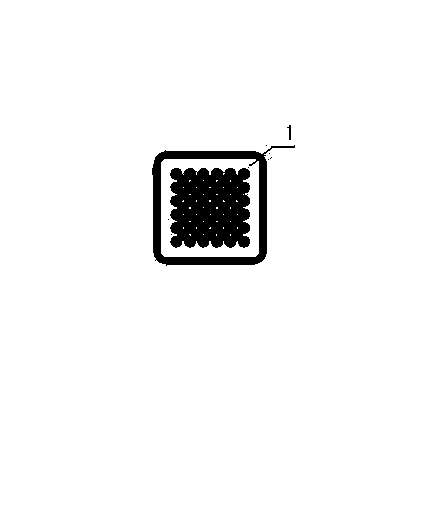

The invention relates to a square micro-needle massager manufacturing technical process. The technical process includes a square micro-needle massager structure and the manufacturing technical process thereof. The square micro-needle massager structure comprises a plastic needle piece suit, a square cover and a protecting cover, a plastic needle piece and a hole shell are arranged inside the plastic needle piece suit, the plastic needle piece comprises a plurality of rows of needle holes same in spacing and a plurality of rows of vent holes same in spacing, the rows of the needle holes and the rows of the vent holes are arranged in a crisscross manner, the hole shell is provided with a plurality of rows of square holes same in spacing, the square holes and the vent holes in the plastic needle piece are identical in spacing and communicated mutually, the hole shell is nested in the square cover, the vent holes are arranged in the rear portion of the square cover, and the square cover is nested in the protecting cover. The square micro-needle massager manufactured in the technical process is smooth and tidy in appearance, free of gaps and hygienic and convenient during use, sterilizing and cleaning can be performed thoroughly, the number of times in use of a product is increased, and attractiveness of a micro-needle roller is improved.

Description

Technical field [0001] The invention relates to a beauty auxiliary tool, in particular to a manufacturing process of a square microneedle massager. Background technique [0002] There are two types of microneedle massagers currently on the market. One is composed of overlapping discs and discs, and the other is composed of straight sheets inserted from both ends of the needle wheel. There are many gaps in the microneedle rollers of these two structures, so that dirt such as blood stains and dander will remain between the gaps during use. It is inconvenient for disinfection and cleaning, which affects the use, and the aesthetics of the product is greatly reduced due to the influence of the gap. And because of the structure, the original product can only be a disposable consumer product, which makes the product expensive; and the original microneedle roller cannot be sterilized better because of the inability to high temperature and high pressure sterilization. The plastic surg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61M37/00A61B17/00

CPCA61M37/0015A61M2037/0023

Inventor 解云龙

Owner QINGDAO KANGWEILONG COMMODITY COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com