Power system with reverse blow-down capacity, vehicle body and aerial work platform

A power system and reverse technology, applied in the power system, car body, and aerial work platforms, can solve the problems of complex structure of the power system, debris or dust falling, unfavorable manual cleaning, etc., and achieve high cleaning efficiency and good effect , clean up thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further described below with reference to the accompanying drawings and exemplary embodiments, wherein like numerals in the drawings refer to like parts throughout. Also, if a detailed description of known art is not necessary to illustrate the features of the present invention, it will be omitted.

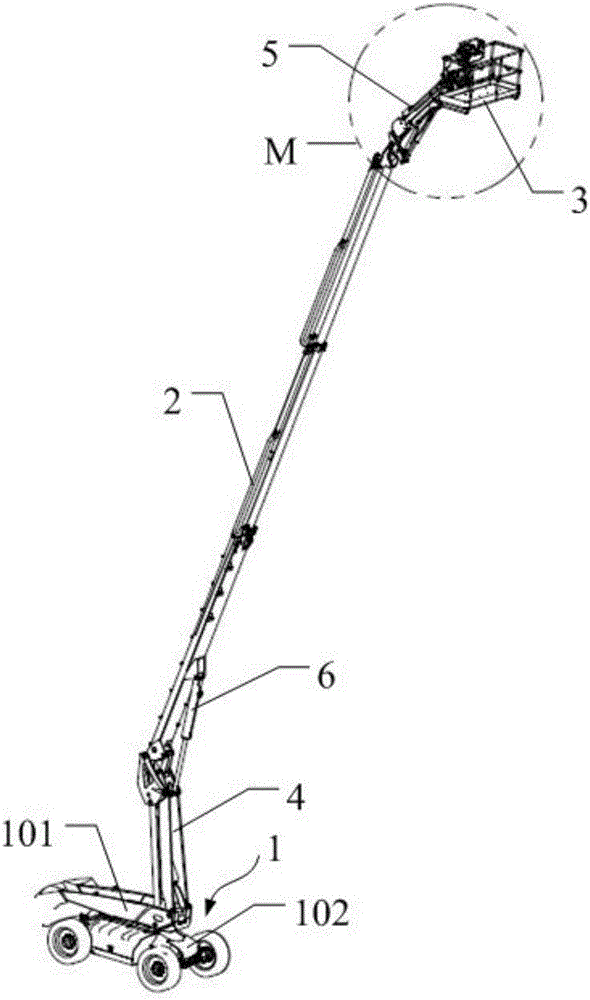

[0045] A schematic structural diagram of a typical embodiment of an aerial work platform provided by the present invention is as follows: Figure 1-17 As shown, the aerial work platform includes a vehicle body 1 , a telescopic transmission assembly 2 pivotally connected to the vehicle body 1 , and an operation table 3 connected to the end of the telescopic transmission assembly 2 through a telescopic connecting assembly 5 .

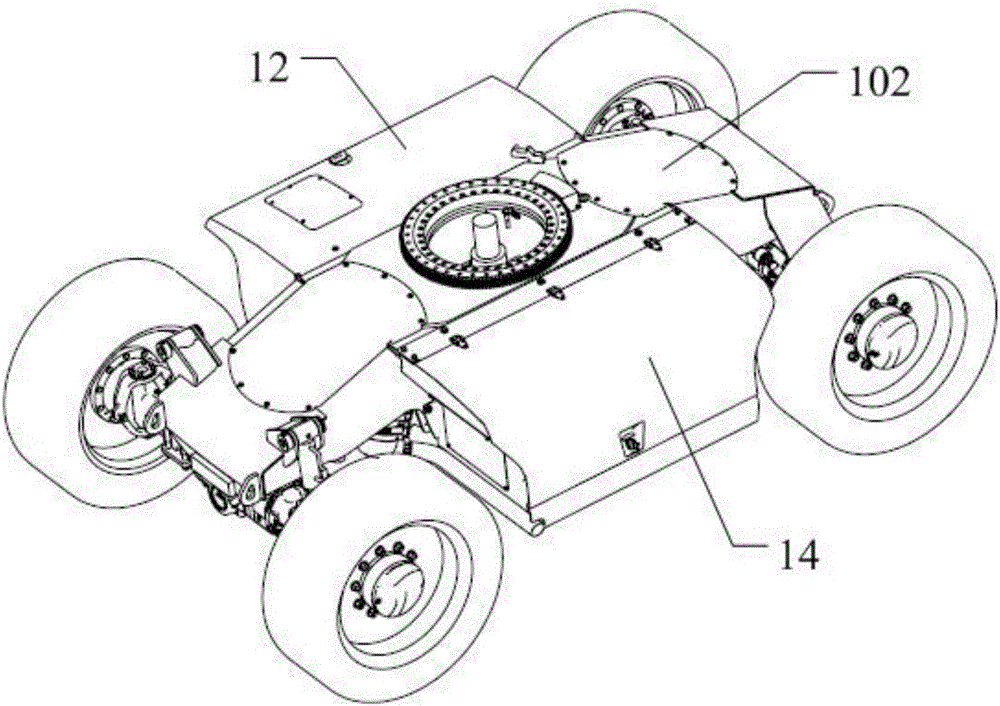

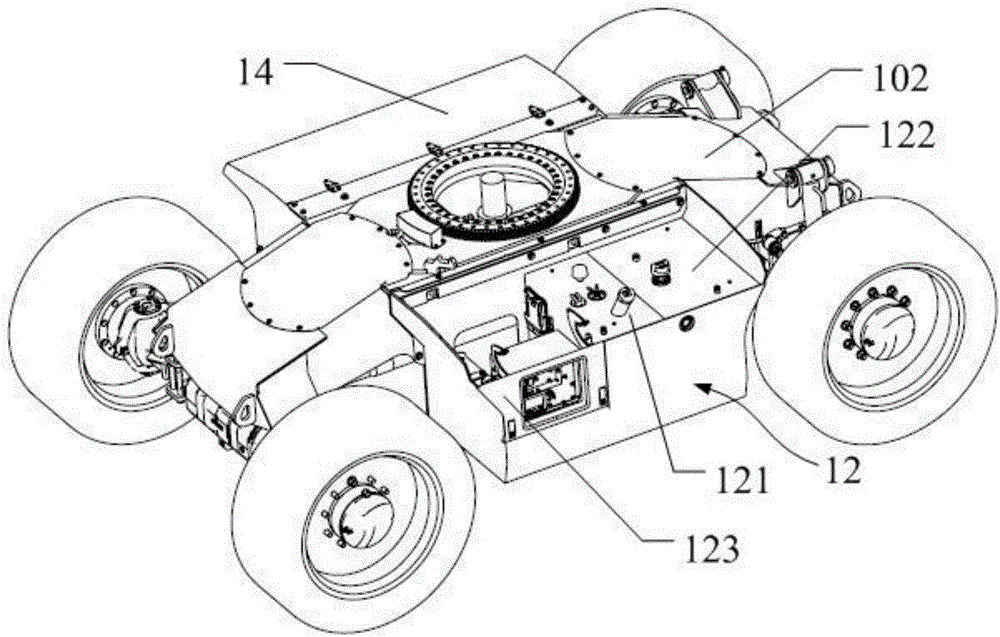

[0046]It should be noted that the vehicle body 1 includes a frame 102, a drive system, a fuel tank 121 and a hydraulic oil tank 122; the drive system includes a power system 14, a transmission mechanism, a control system, a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com