Plastic film residue pickup machine

A technology for picking up and recovering residual film, applied in the field of agricultural machinery, can solve the problems of unclean cleaning and recycling of plastic film residues, no loosening effect, and inability to clean and recover plastic film residues, so as to maintain sustainable development and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

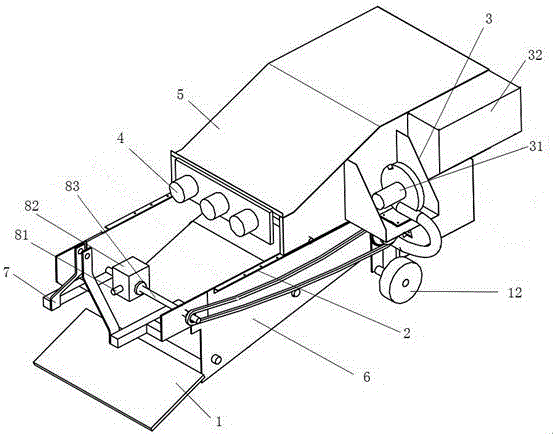

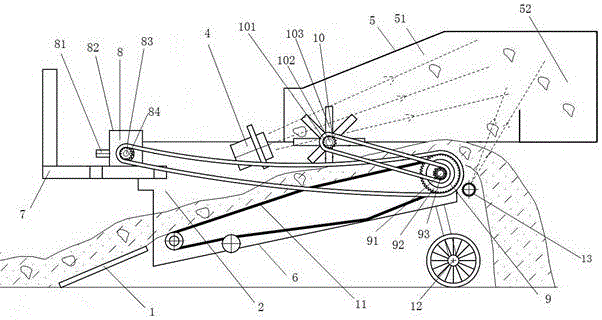

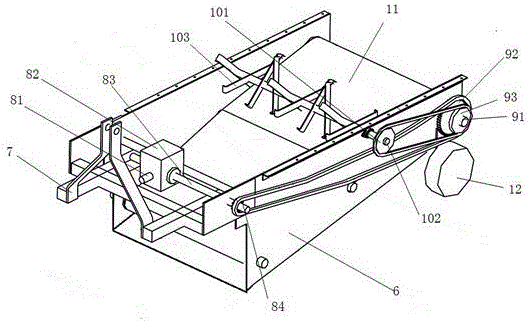

[0027] figure 1 Shown is a kind of residual film pick-up machine, comprising mound plate 1, picking up car body 2, wind power generating device 3, No. 1 air outlet device 4 and residual film collecting box 5, the front end of picking up car body 2 is provided with inlet, rear The end is provided with an outlet, and the soil lifting plate 1 is arranged obliquely in front of the picking-up car body 2, and the high end is connected with the entrance of the picking-up car body 2, and the interior of the picking-up car body 2 is provided with a soil conveying part 11 and a stirring part 10, and the soil Conveying section 11 is arranged along the direction of import to exit, and stirring section 10 is arranged on the top of soil conveying section 11, and residual film collection box 5 is arranged on picking up vehicle body 2 tops, and No. 1 air outlet device 4 is arranged on the place ahead of stirring section 10, And link to each other with wind power generating device 3 by air duc...

specific Embodiment 2

[0029] figure 2 Shows a cross-sectional structure of a residual film pick-up machine. This embodiment further optimizes the structure of the present invention on the basis of the specific embodiment 1. There is a second outlet at the end of the exit of the above-mentioned picking-up car body 2. Wind device 13, and the setting height is lower than the height of one end of the soil conveying part 11 near the outlet, the No. 2 air outlet device 13 is connected with the wind power generating device 3 through the air duct, and the air outlet direction of the No. 2 air outlet device (13) faces The air inlet on the residual film collection box (5).

[0030] No. 2 air outlet device 13 is set outside one end of the pick-up car body 2 outlet because when the soil comes out from the outlet, a parabola can be formed, and below the parabola formed by the soil, upward blowing can remove the mulch that has not been cleaned up in the loose soil Residues are blown into the residual film coll...

specific Embodiment 3

[0031] This embodiment further optimizes the No. 2 air outlet device 13 on the basis of the specific embodiment 2. The No. 2 air outlet device 13 is tubular, and more than two air outlets are arranged on the tube wall. This is based on the principle of aerodynamics. Because the diameter of the pipe is small, the wind pressure generated under the same conditions is greater, and the wind speed from the air outlet is also greater. In this way, a small-power fan can be used to generate a higher wind speed, which is more conducive to The collection of residual film is more convenient for installation due to the small space occupied by the tubular air outlet device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com