Coating machine heating control method and coating machine

A technology of heating control and coating machine, which is applied in the field of heating control of coating machine and coating machine, which can solve problems such as troublesome installation and disassembly, inconvenient use, unreasonable design, etc., and achieves convenient installation and disassembly, convenient cleaning, excellent structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

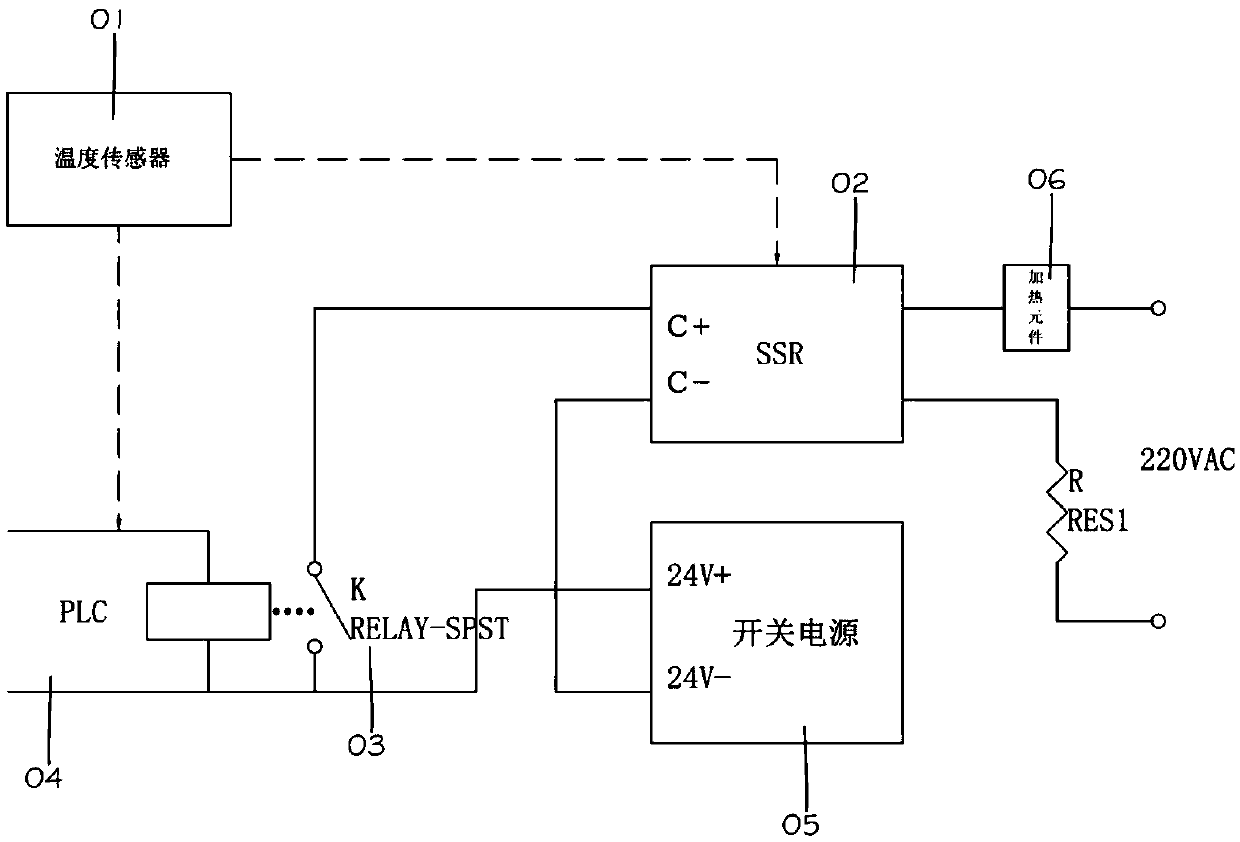

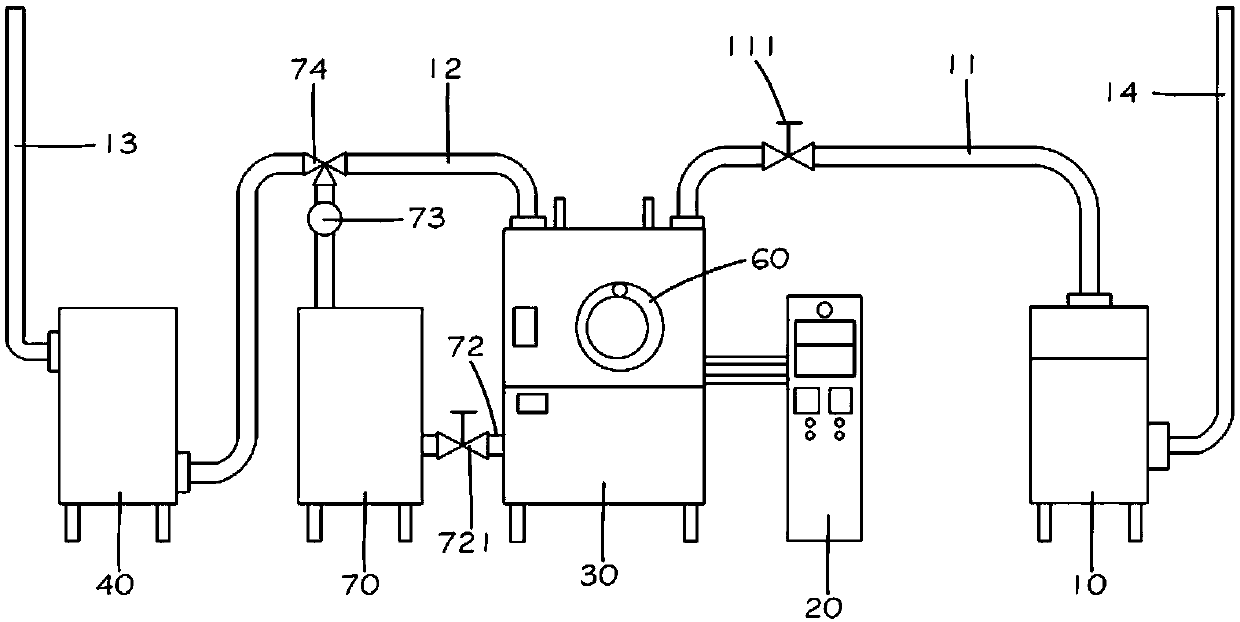

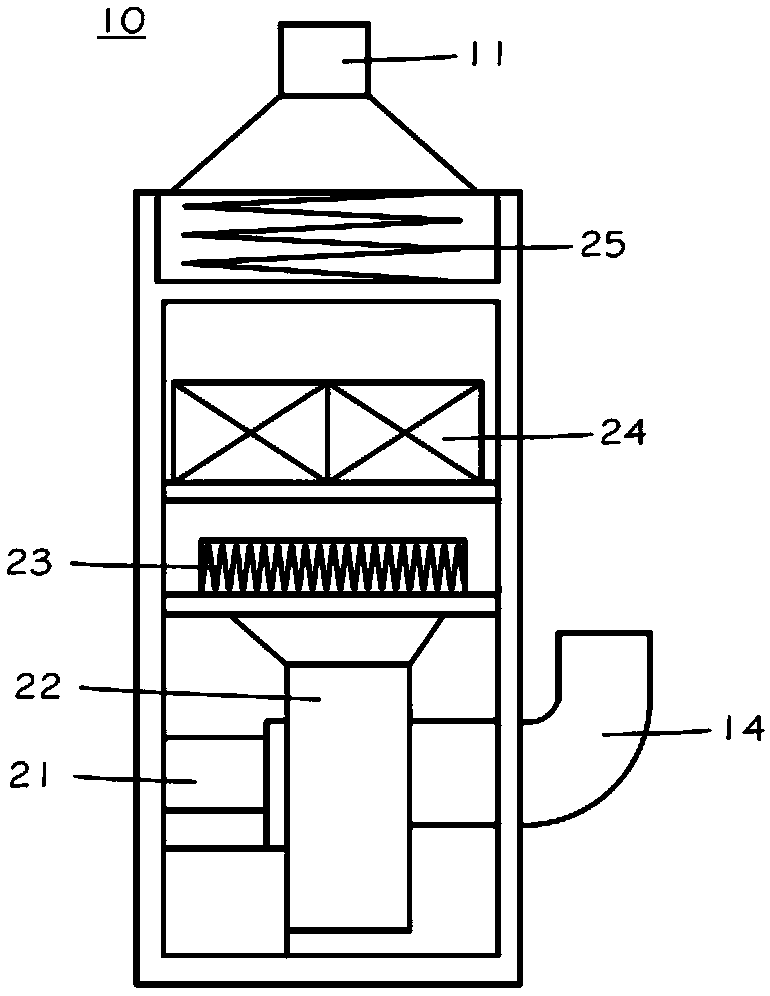

[0039] Such as figure 1 The heating control method of this coating machine of the present invention shown, it comprises temperature sensor 01, solid state relay 02, SPST relay 03, PLC controller 04, switching power supply 05, a heating element 06, wherein temperature sensor 01 It is used to detect the temperature value in the drum of the coating machine; the solid state relay 02 is used to control the on-off frequency of the heating circuit, which includes a PID calculation element, which is connected to the temperature sensor 01, and the PID calculation element can calculate the temperature value and its internal The deviation between the set values; the SPST...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com