Rotary-drilling and bottom-expanding construction process for cast-in-place pile

A technology for bottom-expanding cast-in-place piles and construction technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as unguaranteed performance, excessively thick pile bottom sediment, and calculation of bearing capacity, so as to improve the allowable bearing capacity. force, change the size of the pile bottom, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

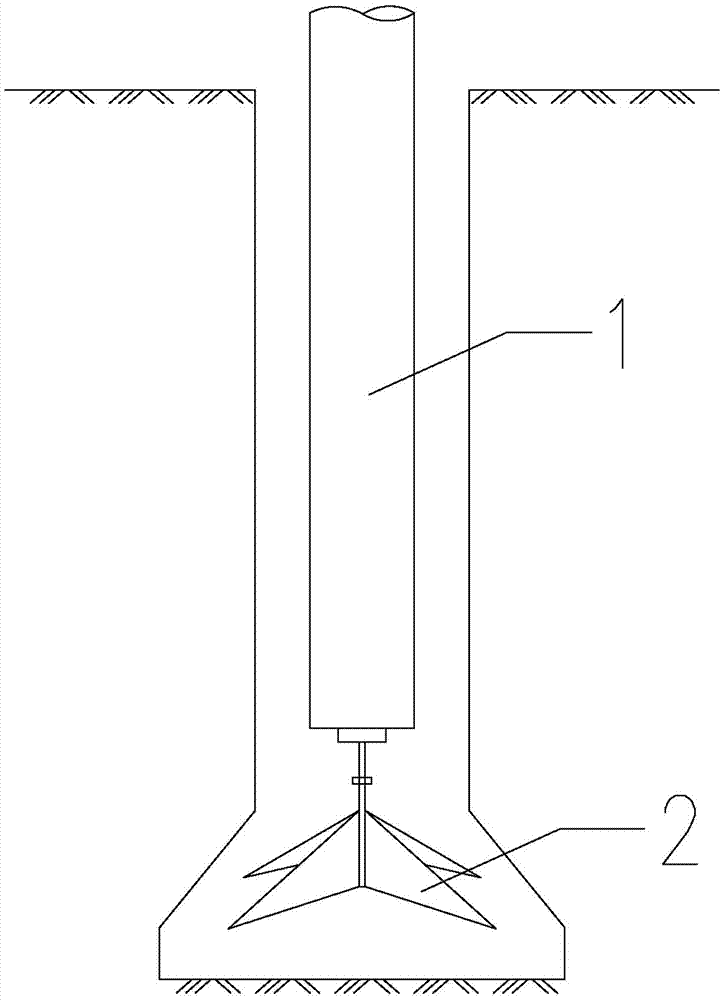

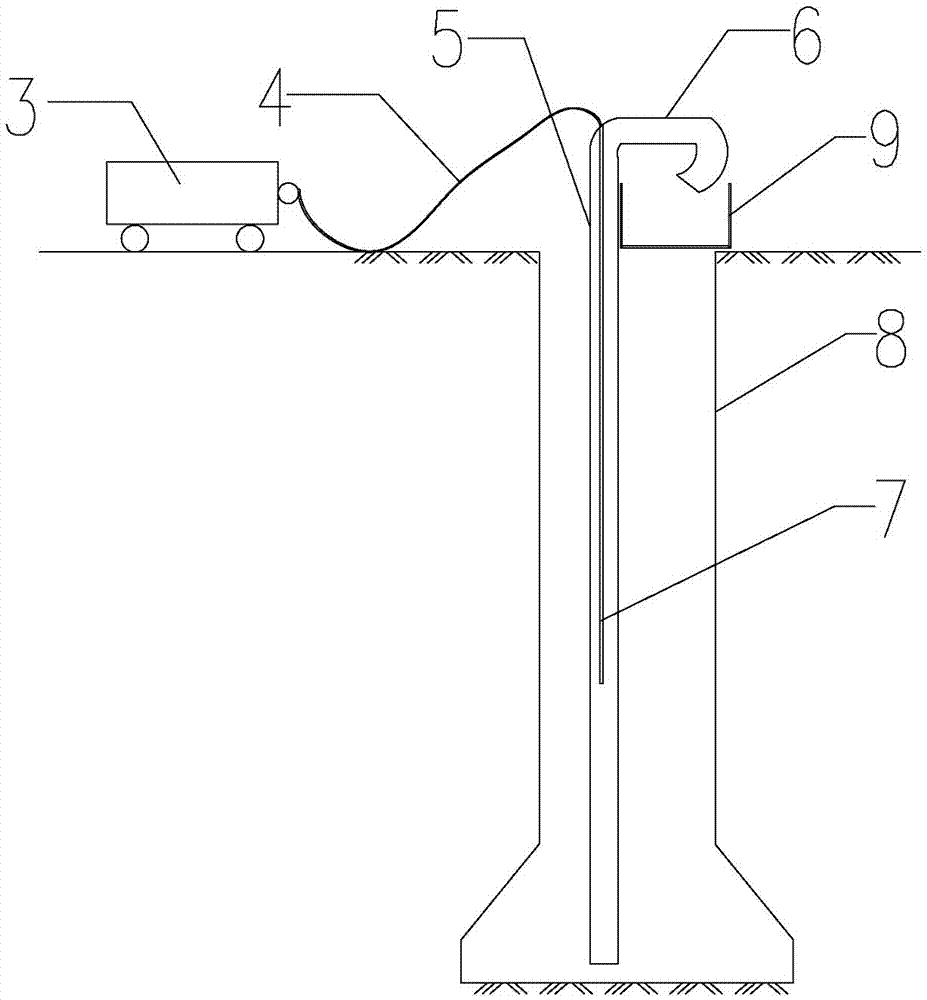

[0049] A construction technique for rotary-dug bottom-expanding cast-in-place piles, which adopts a rotary drilling rig to rotary-dig to form a hole. The screw diameters of the middle part of the drill bit of the rotary drilling rig are equal, and the diameters of the upper screw and the lower screw are gradually reduced, that is, the drill bit The screw is composed of equal-diameter screw, upper screw and lower screw. Generally, the length of the equal-diameter screw is 1 to 2 meters.

[0050] Its construction process includes the following steps:

[0051] Step 1: Stake out and position

[0052] Including control point surveying and pile position surveying; firstly, control point surveying, that is, according to the control network points provided by the owner, the main axis of the building is measured on the ground, and pile positions, roads, and stockyards are required to be avoided; secondly, On the basis of the survey and design of the control points, the polar coordinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com