Ultrasonic on-line anti-scaling and descaling system for heat-exchange device

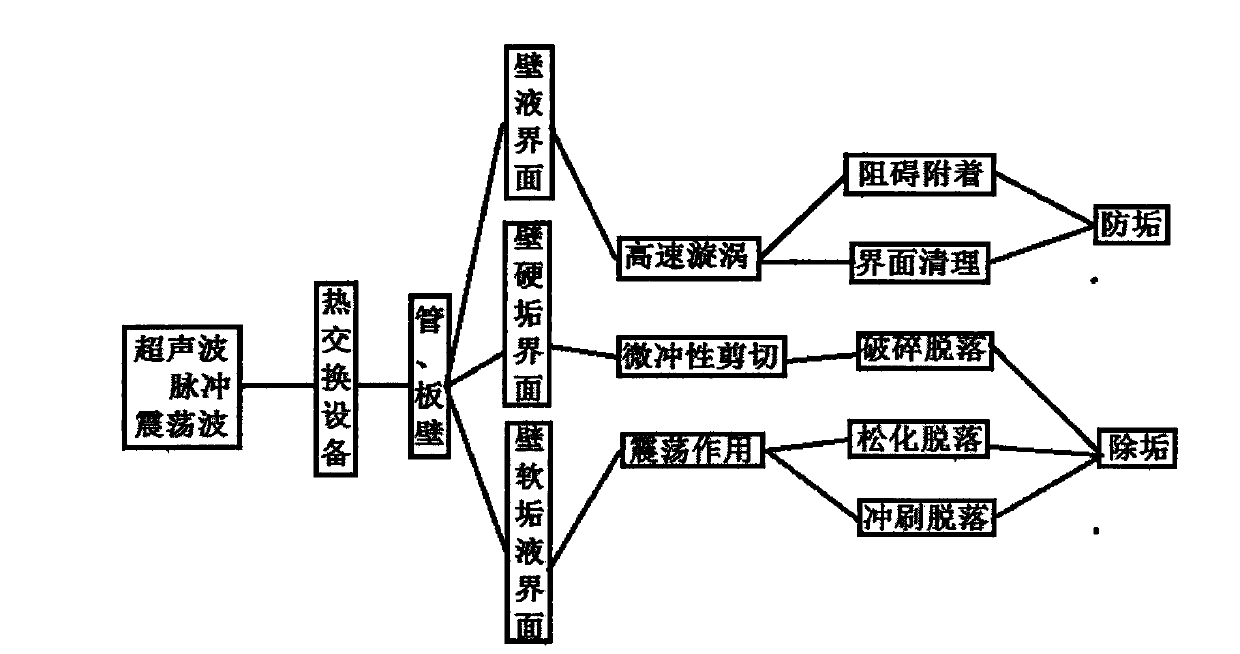

A kind of heat exchange equipment and ultrasonic technology, which is applied in the field of descaling and ultrasonic pipeline anti-scaling to achieve full anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The ultrasonic on-line anti-scaling and descaling system for heat exchange equipment includes an ultrasonic sounding unit and a transducer electrically connected to the ultrasonic sounding unit, and the ultrasonic sounding unit includes a commissioning and control unit. The transducer is a strong magnetostrictive transducer. Due to its scalability, it can be flexibly installed in any position where different pipes and pipes need to be installed.

[0017] In this embodiment, the commissioning and control unit can be directional designed for ultrasonic acoustic parameters in different application environments. The commissioning and control unit includes a central controller and an ultrasonic signal feedback unit. The commissioning and control unit uses the central controller to determine the ultrasonic acoustic parameters according to the ultrasonic attenuation information inside the pipeline fed back by the ultrasonic signal feedback unit. Perform commissioning. The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com