Scale removing device for heat exchange pipe

A technology of heat exchange tubes and sleeves, which is applied in the descaling device of heat exchange tubes and the field of heat exchange in metallurgical production. The effect of increasing the heat exchange area, sufficient and effective waste heat, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

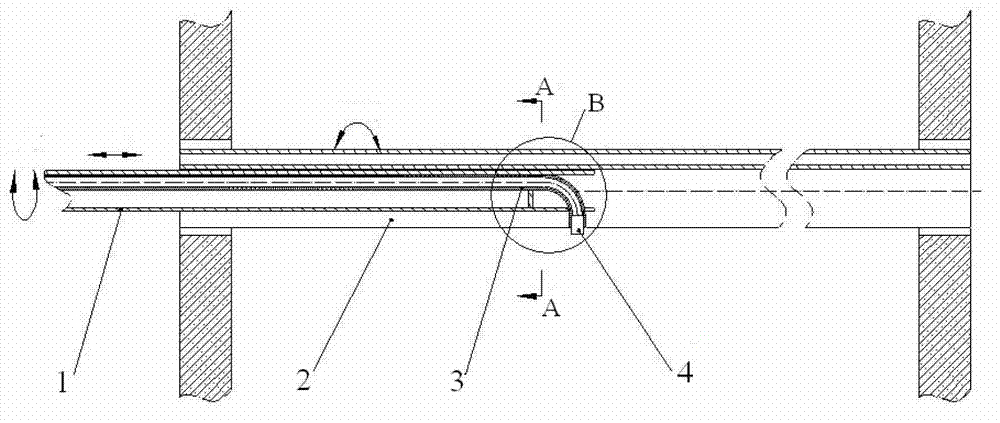

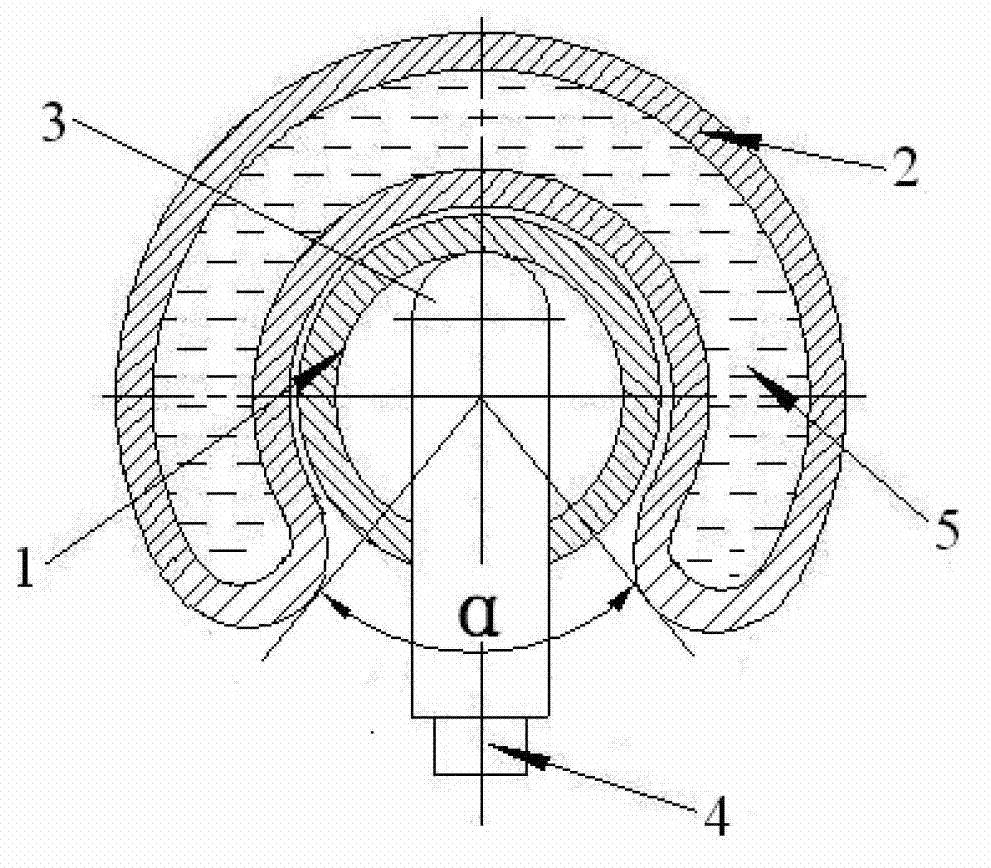

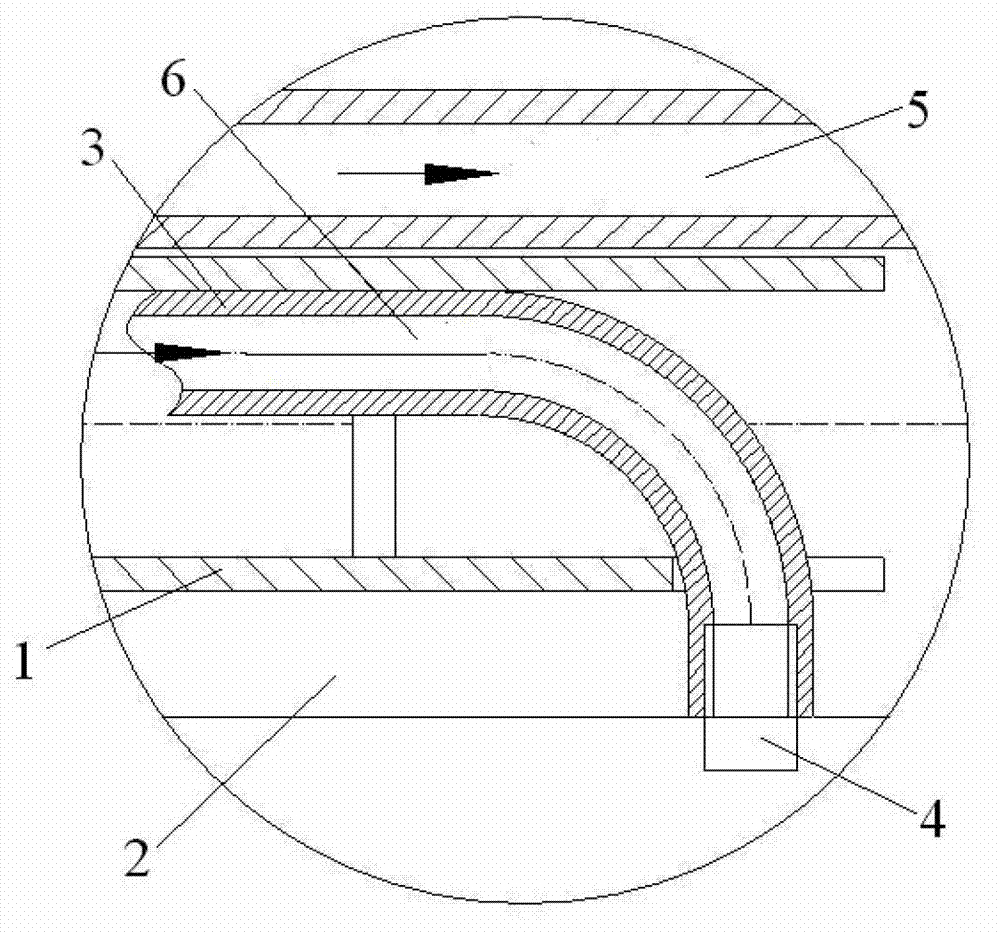

[0021] Such as figure 1 , figure 2 and image 3 The expressed structure of the present invention is a descaling device for heat exchange tubes. The invention adopts a rotatable, stepping and moving spraying method to descale the heat exchange tube, and is a high-efficiency descaling method that uses powdery high-speed particle beams to impact the surface of the heat exchange tube. It is suitable for metallurgy, steelmaking, thermal power, ceramics and other industries, as well as various industries with large heat exchange stations for waste heat utilization. These enterprises consume a lot of energy. If they cannot fully excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com